1. Introduction

Kevlar fiber is widely recognized for its potential and numerous advantages, prompting many researchers to conduct in-depth analyses of its mechanical properties. There is a famous study by PL Walton et al. [1]. The research focuses on the response of Kevlar 49 fiber under creep load. The experiment involved placing 49,900 mm long filaments under a creep load of 830 to 1830 MPa for 4,000 days. The experimental results reveal important insights into the behavior of Kevlar 49 fibers under creep conditions. It has been observed that the creep strain accounts for 13% of the initial elastic strain at a stress rate of 1830 MPa. Interestingly, after an extension of 4000 days, the creep strain increased to 14.6%. These results highlight the deformation properties of Kevlar 49 fibers over time and provide valuable information for understanding their long-term performance under continuous load. In another study cited, researchers explored the relationship between the number of layers of Kevlar fabric and its electrical resistance [2]. The results show that the resistance increases with the increase of fabric layers. This suggests that the protection of Kevlar fibers can be enhanced by the use of multiple layers, which has implications for applications that require improved bullet-proof properties or impact resistance. MS. Sebastian et al. studied the viscoelastic properties of Kevlar 29 fabric strips by transient and harmonic tests [3]. They concluded that the energy storage modulus of the fabric increases with the loading rate, which means that Kevlar 29 exhibits greater stiffness at higher loading rates. In addition, the loss factor (a measure of energy dissipated during cyclic loading) was found to decrease as the loading rate increased. These findings contribute to a comprehensive understanding of the dynamic response of Kevlar 29 fabrics and their potential applications in a variety of load-bearing scenarios. In a study conducted by D. Zhu et al., the dynamic tensile properties of Kevlar 49 fabrics with different scale distances were investigated in the range of different strain rates [4]. The researchers found that dynamic properties such as Young's modulus, tensile strength, maximum strain, and toughness are significantly affected by the strain rate. This means that the mechanical properties of Kevlar 49 fabric are highly sensitive to its rate of deformation. Understanding this dependence on strain rates is critical to designing Kevlar structures and protective materials that can withstand different load conditions. After we have understood these properties of kevlar here, we also need to understand some properties of some existing kevlar composite and their corresponding applications below.

2. Properties and applications of MS-Kevlar

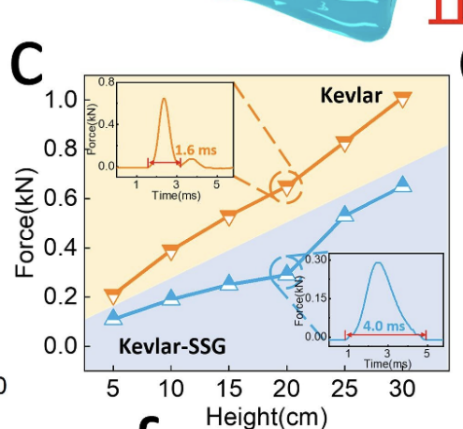

In Zhou Jianyu's research article, they conduct in-depth research on the development of new Kevlar composite materials [5]. It is called MS-Kevlar. The composite has excellent mechanical properties and enhanced thermal management capabilities for smart protection applications. These researchers show the optimized performance features of MS-kevlar. MS-kevlar exhibits excellent mechanical strength and modulus. This means it withstands high impact. Taking 20-layer MS-kevlar as an example, MS-Kevlar can dissipate 55.4% of the force under low-speed impact (Figure 1). In addition, the experiments demonstrated that the impact resistance of MS-Kevlar remained stable through multiple impacts. After a severe impact of 30 cm, MS-Kevlar's resistance increases.

Figure 1. The impact force of 20 layers MS-Kevlar [5].

In addition, the researchers successfully integrated thermal management functions into the Kevlar composite. By adding advanced thermal conductivity materials, such as phase change materials (PCM) or thermal conductivity additives, the composite effectively dissipated the heat generated during operation. This ability to regulate and manage thermal energy is critical for applications where temperature control is critical, such as electronic devices, aerospace components, and protective clothing. Jianyu Zhou and other researchers also said that because MS-kevlar has excellent mechanical properties and stable electrical properties, the intelligent protection capability of the composite is achieved through the integration of smart materials and sensing components. By embedding sensors or actuators in Kevlar composites, it is able to monitor, detect and respond in real time to external stimuli, such as shocks, temperature changes, or deformations. This capability enhances the overall safety and reliability of the composite material, making it suitable for applications requiring adaptive and responsive protection. The case mentioned in this paper is the realization of a wireless window intelligent alarm system. When the window is broken, it can send a signal to the phone's Bluetooth, so that it can accurately understand the impact location and stay away from the danger area in time.

3. Properties and applications of SSG@Kevlar

Ting Fan and other scientific researchers mentioned Kevlar fabric as the core protective layer, reduced graphene oxide (RGO), and nano-silica/shear thickening gel (STG) as the functional layer of three-layer composite materials [6]. The developed composite, SSG@Kevlar, was used in the manufacture of multi-functional soft body armor. The material manufacturing process consisted of dipping Kevlar fabric with three coaxial layers. Kevlar fiber, as the core material, had excellent mechanical properties and the ability to withstand impact loads. Conductive RGO nanosheets were introduced into the fabric surface to achieve strain sensing and electric heating functions. Shear thickening gels (STG) provided exceptional shock buffering for this composite. SSG@Kevlar composites offered a variety of desirable properties for soft body armor applications. It maintained good flexibility and wear resistance, similar to pure Kevlar fabric, with a low bending modulus. It also showed better air permeability compared to Kevlar, although slightly less than surgical masks. The mechanical properties of the composite were evaluated, and the tensile strength was slightly reduced compared to Kevlar fabric due to the addition of SiO2/STG. However, SSG@Kevlar fabric composites maintained excellent mechanical stability and structural integrity under cyclic tensile loads. In addition, SSG@Kevlar fabric composites exhibited piezoresistive properties that make them suitable for strain-sensing applications. The relative change of resistance (RCR) increased monotonically with the increase of tensile strain, and the composite exhibited high linearity in the strain range of 0-1.7%. The strain coefficient (GF) calculated for this range was significantly higher than that of conventional metal strain gauges and previously reported fabric-based strain sensors. SSG@Kevlar fabrics also demonstrated a shorter response time. In general, the SSG@kelvar developed by Ting Fan and other technicians solves the limitations of traditional soft armor and provides a solution to improve anti-elasticity, comfort, and functionality. Excellent mechanical properties, strain sensing capabilities, and improved impact and flame resistance provide enhanced protection and functionality for soft body armor designs.

4. Properties and applications of Kevlar-reinforced composites

M. Mohammed Mohaideen et al. studied Kevlar-reinforced composites (KRCs) and their potential applications in their article [7]. Their report provides valuable insights into the performance of KRC materials. The study likely involved testing the composites under various loading conditions, such as tensile, compressive, flexural, and impact tests. The results of these tests shed light on the specific mechanical behavior and performance characteristics of KRC

Bilal Zahid et al. introduced a vacuum bag method for fabricating Kevlar-based composites, enhancing mechanical properties through proper compaction of Kevlar fibers within the matrix material [8]. Herbert et al. focused on Kevlar-49 reinforced composites with thermoplastic and thermosetting matrices, utilizing theoretical models to predict mechanical properties and assessing their accuracy through experimental comparison [9]. This analysis elucidates the interplay between material composition, processing parameters, and mechanical attributes. Meanwhile, Ananda Rao et al. conducted empirical investigations on Kevlar/epoxy composites, contrasting their mechanical traits with mild steel and evaluating their potential as substitutes in diverse applications, involving tests under various loading conditions [10]. Based on the experimental results reported by Ananda Rao et al., the average tensile stress corresponding to KRC was found to be 944.48 N/mm². This result suggests that KRC exhibits excellent toughness and mechanical strength. Such favorable mechanical properties make KRC suitable for applications in automotive technology, where lightweight materials with high strength and toughness are desired. Additionally, KRC materials can also find applications in aerospace technology, where the combination of strength and low weight is crucial for achieving fuel efficiency and overall performance in aircraft structures. Overall, these studies provide valuable insights into the mechanical properties, fabrication methods, and potential applications of KRC, highlighting their promising characteristics for various industries.

5. Properties and applications of Kevlar aerogels

Yongfang Chen et al. reported that Kelvar also has breathable and unidirectional liquid permeation properties, which could help designers design versatile flexible wearable Kevlar aerogels [11]. Wearable materials have become an important part of daily life and an essential requirement for individuals. Functional wearable materials with regulated heat management, air permeability, and one-way liquid penetration characteristics are becoming more and more crucial to enhancing human comfort as the economy grows and living standards rise. At the moment, people use electric blankets, air conditioners, and other energy-hungry devices to keep homes at a comfortable temperature, which uses a lot of energy. To solve this problem, a personalized and accurate thermal management strategy for the human skin microenvironment was proposed. Radiation, thermal, and electric heating are a few thermal management strategies that might enhance human comfort. Radiative insulation, which involves adjusting the infrared reflectivity of a material's surface to reflect heat radiated by the human body, has shown promise in wearable materials. For instance, a fiber film with high infrared reflection and sunlight absorption can raise a person's skin surface temperature by 8.5 °C when compared to polyester fabric. Controlling the collision of air molecules within the fabric is another method for reducing heat convection in materials used for clothing. Aerogel materials exhibit superior thermal insulation qualities and have a smaller aperture than the typical free route of air molecules. Kevlar nanofiber aerogel/phase change material was created by Lyu et al. with a strong thermal management capacity and infrared emissivity, highlighting the film's remarkable thermal insulation capabilities [12]. The Joule thermal effect is used in the third method to control thermal energy by transforming electrical energy into heat. The graphene material is known for its high electrical conductivity and has been used to make wearable thermal management devices. In order to accomplish effective joule heating, Hazarik et al. developed a braided Kevlar fiber-based device with metal nanowires and a conductive network of graphene oxide [13].

Yongfang Chen and colleagues conducted experiments to fabricate and characterize a material known as Al-KAM-PDMS. This material consists of a Kevlar aerogel film coated with aluminum (Al) nanoparticles and a hydrophobic polydimethylsiloxane (PDMS) layer. The fabrication process involves dissolving Kevlar fibers in dimethyl sulfoxide (DMSO) using potassium hydroxide (KOH) as a solvent, resulting in nanofibers with ordered structures. A light-yellow material is created when these nanofibers are transferred to a solution of deionized water and tert-butanol for solvent exchange. By using freeze-drying, magnetron sputtering, and waterproof spraying to generate the Al-KAM-PDMS material, a structure with a hydrophobic PDMS side, a Kevlar aerogel membrane substrate, and connected Al nanoparticles is created. The successful production is confirmed by a number of characterization methods, with energy dispersive X-ray spectroscopy (EDS) revealing the existence of Al nanoparticles on the surface of the Kevlar aerogel. X-ray diffraction (XRD) patterns reveal changes in crystal phases, and Fourier transform infrared spectroscopy (FT-IR) shows distinct chemical bonds in the components. X-ray photoelectron spectroscopy (XPS) analysis provides insight into element composition and surface functional groups. The material exhibits unidirectional liquid permeability and enhanced infrared reflectance, making it suitable for applications such as aerogel film production, thermal management, and insulation. In summary, the multi-functional flexible material Al-KAM-PDMS has been successfully developed, combining unique properties such as unidirectional liquid penetration, enhanced thermal insulation, improved mechanical strength, high infrared reflectivity, and permeability. This innovative material is made by combining aluminum nanoparticles, Kevlar aerogel film, and PDMS chloroform solution to achieve unidirectional liquid penetration through asymmetric wettability. It is worth noting that the PDMS coating not only enables rapid liquid penetration but also greatly enhances mechanical strength. In addition, Al-KAM-PDMS exhibits excellent air permeability and improves the overall comfort of the wearer. This exceptional combination of properties makes Al-KAM-PDMS a promising candidate for future wearable materials with diverse functions.

6. Conclusion

Together, Kevlar and its composites revolutionize the field of materials science, providing superior strength, durability, and resistance. But there are problems. For example, UV sensitivity, relative brittleness at lower temperatures, and high production costs are among the issues. But for now, engineers can compensate for those shortcomings and amplify their advantages by combining Kevlar with other materials. The composite materials mentioned above are a good example. This class of materials has excellent resistance to impact and ballistic threats, as well as excellent chemical and heat resistance, making it a must-have for bulletproof vests, helmets, aerospace components, and industrial equipment. These composites are already used in the aerospace, automotive, sporting goods, and personal protective equipment industries. With the increase in the invention of composite materials, Kelvar products will be more widely used. For example, protective covers for vehicles can be made. At present, there is no good material on the plane to make a protective cover in case of emergency, but Kevlar material is very suitable for making such products. The possibilities for Kevlar's future are endless because of the composite material.