1. Introduction

Public buildings are buildings for people to carry out various public activities, including tourist buildings, commercial buildings, office buildings and so on. In the construction of traditional public buildings, most of China adopts reinforced concrete structure, and the actual operation involves many complex processes such as concrete mixing and pouring, which not only cannot guarantee the construction efficiency, but also easily cause serious pollution to the surrounding ecological environment, resulting in serious contradiction between the development of the construction industry and the requirements of energy-saving social construction. Under this situation, more and more experts and scholars began to explore new construction methods. The main purpose is to promote engineering construction to better adapt to the concept of green development, that is, to ensure the quality of the project while reducing environmental pollution as much as possible. The fabricated green steel structure was born under this background [1]. Steel structure is the main structure in prefabricated building engineering. The so-called prefabricated building refers to the construction project that processes the main parts of the construction project such as the structural system, the internal system, and the peripheral protection system through the prefabricated production method, and the various systems of this type of construction project can be coordinated and unified. Vigorously promoting prefabricated steel structure in China is an important means to comply with the requirements of supply-side structural reform and the strategy of urban green development. Its application in the construction of public buildings can successfully complete the construction task based on the concept of "assembly" and effectively reduce unnecessary waste of resources and energy. And it can minimize the pollution of the ecological environment in the construction process, improve the construction efficiency, and solve the problem of steel overcapacity [2]. Prefabricated steel structure in the domestic construction industry is no longer a new thing, in the new era, China's full implementation of the green development strategy, coupled with a series of support policies issued by governments at all levels, for the development of prefabricated steel structure has brought unprecedented opportunities. Especially in recent years, the continuous deepening of China's urbanization process, coupled with the in-depth implementation of the sustainable development strategy, has made the country pay more and more attention to the development of prefabricated steel structure buildings. China has introduced a series of policy measures, so that the proportion of prefabricated steel structures in the construction field has been increased. It has brought unprecedented good opportunities for the development of prefabricated steel structure, and prefabricated green steel structure has also been widely used in the construction of public buildings. This has laid a good foundation for the further development of assembled assembly technology. It has effectively improved the level of technical integration, continuously expanded the construction scale of China's prefabricated steel structure building projects, and achieved remarkable economic, social and ecological benefits [3-5].

Under the current environment and future construction demand conditions, the construction project established by using prefabricated steel structure highlights many advantages such as green environmental protection, seismic energy saving, recycling and reuse, which better conforms to the development requirements of the new construction industry and has more positive significance [6]. Therefore, this paper studies the development of prefabricated green steel structure and its application in the construction of public buildings, which has significant practical significance for both the construction technology reform and the sustainable and intensive development of the construction industry.

2. Overview of fabricated steel structures

2.1. The characteristics of fabricated steel structure

Prefabricated steel structure construction projects have the advantages and characteristics of steel structure buildings and prefabricated buildings, which can be summarized as follows. First, the strength is higher, the weight is light, the bearing capacity is larger, and the seismic ability is better. Second, the processing is convenient and the toughness is good. Third, the construction process is simplified, the intensity of manual work is reduced, and the construction efficiency can be improved while ensuring the quality of the project, and can greatly reduce the safety hazards of the construction site. Fourth, the space layout is relatively flexible, the integration level is high, simple and beautiful, and the service life is long. Fifth, it can save energy, protect the environment, and solve the problem of material and energy shortage, can be recycled to meet the requirements of sustainable development. Sixth, it can achieve the goal of public building industrialization and industrial green development, and effectively improve social and economic benefits [1, 7].

2.2. The existing problems of prefabricated steel structure

2.2.1. Poor sound insulation. The sound insulation effect of fabricated steel structure construction is relatively poor compared with that of reinforced concrete structure construction. Although the prefabricated steel structure has been applied to the large-scale construction of public buildings such as shopping malls and office buildings at this stage, there are more and more noise impact events received from building users. Especially for construction projects such as office buildings with high environmental quality requirements, it is urgent to solve the problem of steel structure noise.

2.2.2. The bad insulation effect. Steel itself has significant thermal conductivity characteristics, compared with reinforced concrete structure construction, insulation performance is relatively poor. Especially in the winter when the temperature is low, even if the prefabricated steel structure has a perfect heating system, the indoor temperature is still relatively low, which greatly reduces the satisfaction of building users. Therefore, how to solve the thermal insulation problem of the prefabricated steel structure has become a major problem facing the current construction.

3. Green construction technology

It can be seen from the above analysis that there are still many problems to be improved when the prefabricated steel structure is applied to the construction of public buildings, including large noise and poor thermal insulation performance. Therefore, this paper mainly selects new materials such as lightweight composite panels that meet the requirements of sustainable development, and puts forward effective optimization strategies adopted in prefabricated green steel structures, specifically from the following aspects for in-depth analysis.

3.1. Optimization of sound insulation in prefabricated green steel structures

In order to solve the problem of poor sound insulation effect of assembled steel structure, light composite wallboard can be preferred, which has the characteristics of good sound insulation effect, and the concave and convex groove at the connection position of the board can effectively absorb part of the noise. Combined with the actual testing situation, every increase of 10cm thickness of the lightweight composite wall panel used can reduce the noise of at least 40dB. Compared with the traditional process, it can significantly reduce the material and energy consumption and noise control costs, and effectively alleviate the noise problem [8, 9].

3.2. Optimization of poor thermal insulation performance in prefabricated green steel structures

As mentioned above, the steel structure itself has strong thermal conductivity, so for the problem of relatively poor thermal insulation performance, the construction unit can also start from the aspect of wall panel material, such as the priority choice of lightweight composite wall panel. This kind of inner core not only has good sound insulation effect and strong thermal insulation performance, but also can reasonably adjust indoor air humidity according to the seasonal changes of the environment where the construction project is located [8]. Compared with the traditional steel structure, the selection of lightweight composite wallboard is more convenient and efficient in actual construction, and can save materials and human resources while reducing miscellaneous construction steps.

3.3. Material saving and recycling of fabricated green steel structure

In the construction of prefabricated green steel structure buildings, attention is paid to effectively reducing the use of non-renewable energy. Products related to Ultra-high performance concrete (UHPC) can be used. The use of UHPC products in actual construction, such as silica ash, fiber, can replace the coarse aggregate in traditional building construction, which can improve the cement output while reducing water consumption, so as to save resources and ensure the structure has a high durability.

In addition, most of the construction materials used in the construction have the characteristics of recycling. Taking the light partition panel as an example, as an important part in the construction of prefabricated steel structure buildings, it is mainly used to divide the building space. According to relevant studies, recycling concrete waste in construction and mixing it with fly ash can replace part of aggregate and cement, and then make light partition panel. The compressive strength and bending strength of the recycled products are relatively higher, and they have strong dry shrinkage. In actual construction, cold-formed thin-wall steel can also be used as the keel, which has high reliability and can reduce the amount of steel, and has recyclable smelting. This has a positive effect on saving construction costs and improving material utilization [10].

4. Type of prefabricated green steel structure building system

4.1. New container type steel structure building system

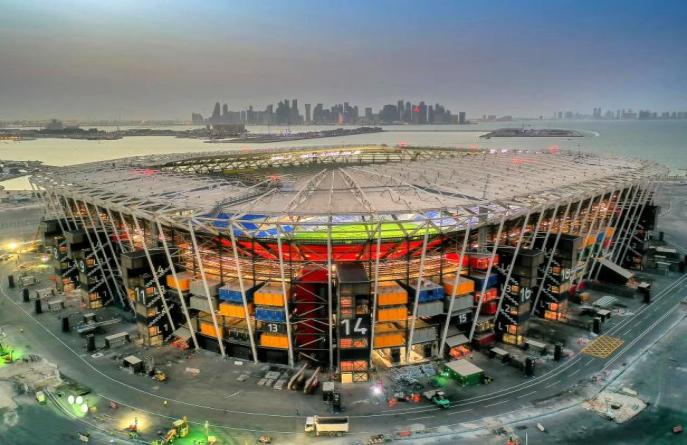

Among the many steel structure building systems, the problem of energy saving and recycling can be solved. It is the most important and intuitive demonstration of the "green" concept in the assembled steel structure system. In addition to the traditional steel structure system, in recent years there has been a leapfrog development in the concept of some new steel structure systems to adopt prefabricated green steel structure technology. Figure 1 shows the 974 stadiums for the 2022 Qatar World Cup, which is different from traditional concrete and steel stadiums, and adopts new technology and recycling and environmental design concept [11]. The modular splicing scheme was chosen. Each container of the stadium was used as an assembly module, detachable chairs, snack stalls, etc., can be preinstalled, and then unified construction. This modular design greatly reduces construction costs, construction time and material waste. After the World Cup, they dismantled the stadium, and each module can be re-spliced into small venues, restaurants, etc., according to new needs, and some of them are also donated to some small and poor countries, so as to recycle materials. This construction method reduces the construction waste generated in the construction process, and can protect the construction site environment well. Finally, when the main material recycling and recycling building is dismantled, the recovery rate of the main structural material of the steel structure is above 90% [9].

Figure 1. Qatar gymnasium [11] (https://www.huitu.com).

4.2. High-rise light steel assembly building system

In addition to implementing the energy-saving green concept of recycling, the green steel structure building system should also pursue the most concise structure to bring the most reliable and stable performance. Taking the Eiffel Tower in Paris, shown as Figure 2 as an example, the structural system of the Eiffel Tower is both intuitive and simple, adopting a staggered structural design, and the tower body is composed of four tall steel columns [12]. These four steel columns are connected by steel beams and steel members to form a stable structure. The hollowed mesh steel frame greatly reduces the weight of the tower. There are three kinds of basic frame elements of the tower body, and the many bars of the tower body are arranged and combined in an orderly manner according to the composition law, so that many form a unity. At the same time, the order of use of the three types of frame elements is also from the bottom up, which is gradually simplified and lightweight, and the stiffness of the structural members is reasonably distributed [13].

Figure 2. Eiffel Tower [12] (https://www.huitu.com).

5. Conclusion

Prefabricated green steel structure is widely used in the construction of public buildings, which can not only improve the construction efficiency and construction quality, but also reduce the environmental pollution in the construction process. At present, the construction project of this structure has become the main trend of the future development of China's construction industry, and the construction technology is bound to develop towards simplification, convenience and standardization. Professionals are required to further increase research efforts to lay a solid foundation for the development of prefabricated green steel structure. Especially in the new period, China has introduced various support policies for the prefabricated steel structure industry. It creates unprecedented opportunities for the development of the industry. the prefabricated steel structure industry is promoted to develop in the direction of energy conservation and environmental protection, overall planning and continuous progress. And from the technical analysis, China vigorously promotes the prefabricated steel structure building system. From the mode analysis, the project construction is gradually changing to the general contracting mode. Based on the advantages of simple steel structure production, modeling design implantation, recycling, and short construction period, it can further promote the optimization of resource allocation in the metallurgical industry and real estate industry, so that limited resources can play a maximum role. It can be seen that prefabricated steel structure buildings are highly consistent with the development needs of green buildings in China, and the prospect is a good situation.