1. Introduction

With the development of science as well as the upgrading of the construction industry, increasingly complex conditions of use have produced a growing demand for the function of building materials. Steel structure is extensively used in various construction fields, including large factories, stadiums and high-rise buildings because of its light weight, high strength, overall stiffness and simple structure. However, many carbon structural steel and low alloy high strength structural steel applied in steel structural engineering have poor corrosion resistance and are easy to rust. After being put into use, regular maintenance is needed, which leads to high maintenance cost in later period. Especially in the case of poor natural conditions or working environment, there are more serious corrosion defects. Such safety problems will be further amplified, when the steel structure is used in offshore engineering projects, resulting in the bearing capacity of the members and the service life of the structure is greatly reduced. In addition, the corrosion problem will not only affect the durability of steel structure, but also seriously affect the safety of steel structure itself. According to the requirements of metallurgy, improving the corrosion resistance of steel structures requires the use of rare metals such as titanium, copper and nickel. This makes the corrosion resistance of the steel structure have to rely on the consumption of a large quantity of anti-corrosion materials. Therefore, the production cost will increase and the production efficiency will reduce. Above all, an excellent material is needed to balance the cost and function of the steel structure.

Under this background, stainless-clad bimetallic steel came into being. Stainless-clad bimetallic steel refers to one type of new steel which is made of two or more kinds of steel through rolling, explosion and other composite processes [1]. This material has the characteristics of two different steel grades at the same time, which can not only retain the performance advantages of high-performance steel, but also retain the advantages of ordinary carbon steel, such as low cost and good stiffness. While reducing the production cost, it also reduces the loss of rare metals and the maintenance cost after being put into use, which makes the stainless-clad bimetallic steel have a high-cost performance, excellent social and economic value.

Ordinary carbon steel has excellent weldability, formability and ductility, while stainless steel is known for its high corrosion resistance, heat resistance, wear resistance, diamagnetism and excellent appearance [2]. Therefore, through reasonable structural design, stainless-clad bimetallic steel can have both of these excellent properties. Compared with stainless steel, the rare metal content of stainless-clad bimetallic steel is extraordinary reduced, so the cost is also reduced. In addition, the stainless steel used on the cladding can play an external anti-corrosion role, can effectively reduce maintenance costs, help reduce life cycle costs and extend the service life of the excellent characteristics. In structural engineering, the use of stainless steel-clad bimetallic steel structure instead of stainless-steel structure or carbon steel structure can reduce costs and have more excellent comprehensive social and economic benefits.

China's imports of stainless-clad bimetallic steel in 1988 have reached 7,000 to 8,000 tons, and the total expected demand in recent years may be 1.9 million tons [3, 4]. In the construction industry, composite stainless-steel materials are mainly used in building curtain walls and railway steel Bridges. Due to the good integrity, flatness and corrosion resistance of stainless-clad bimetallic steel, the overall performance of the actual project is good [5]. In this paper, the production of stainless-clad bimetallic steel (production process, welding process) and mechanical properties (corrosion resistance, composite interface properties) are studied.

2. Production of stainless-clad bimetallic steel

2.1. Production process

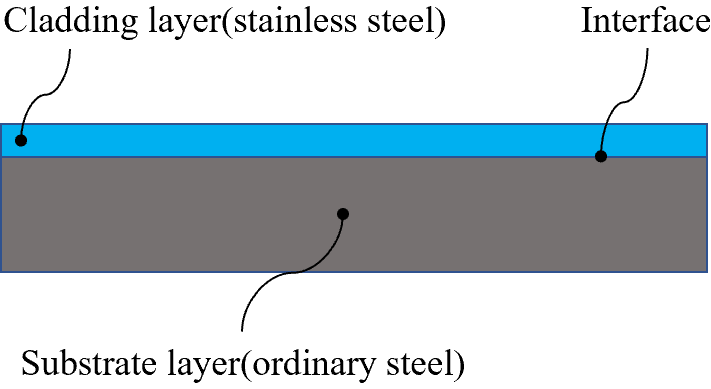

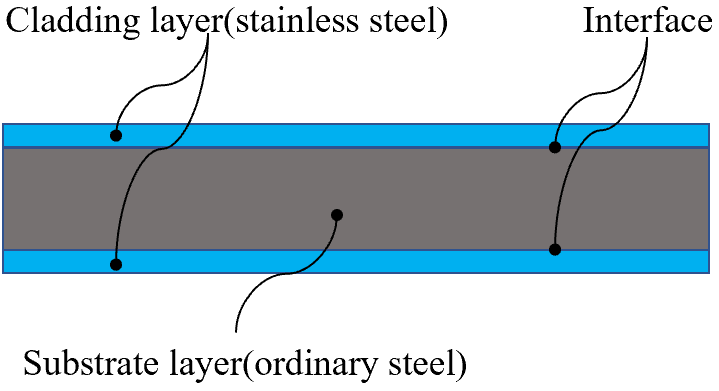

At present, stainless-clad bimetallic steel is one of the composite steels studied and used most in the engineering field. Its cladding material is stainless steel, and its base material is ordinary steel such as low carbon steel. The structure of this material is divided into two layers (cladding layer-substrate layer) or three layers cladding layer-substrate layer-cladding layer), as shown in Figure 1 [6, 7].

Figure 1. Stainless-clad bimetallic steel (steel plate) schematic diagram.

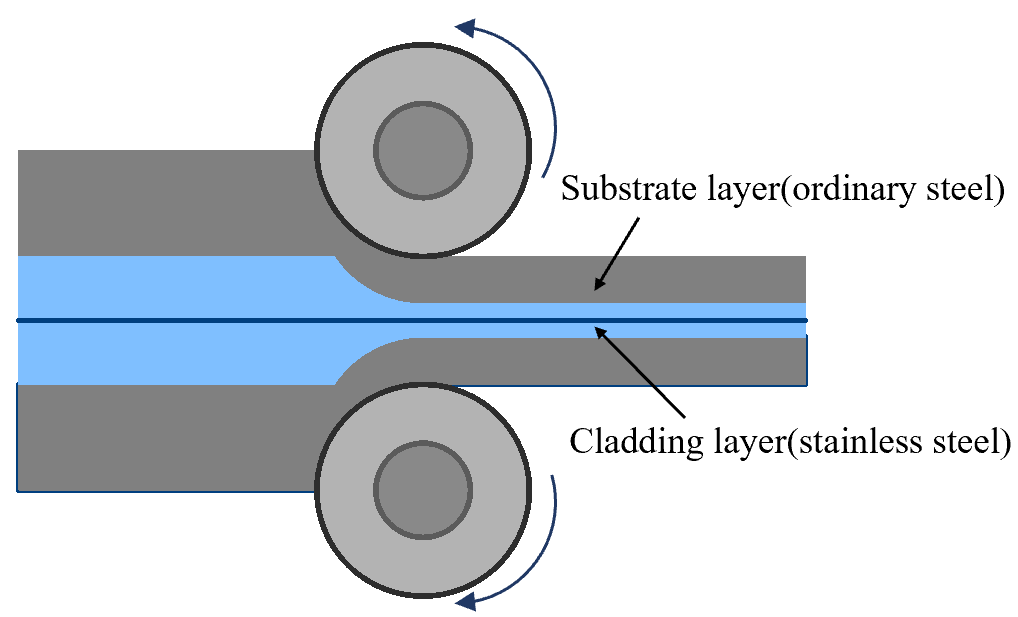

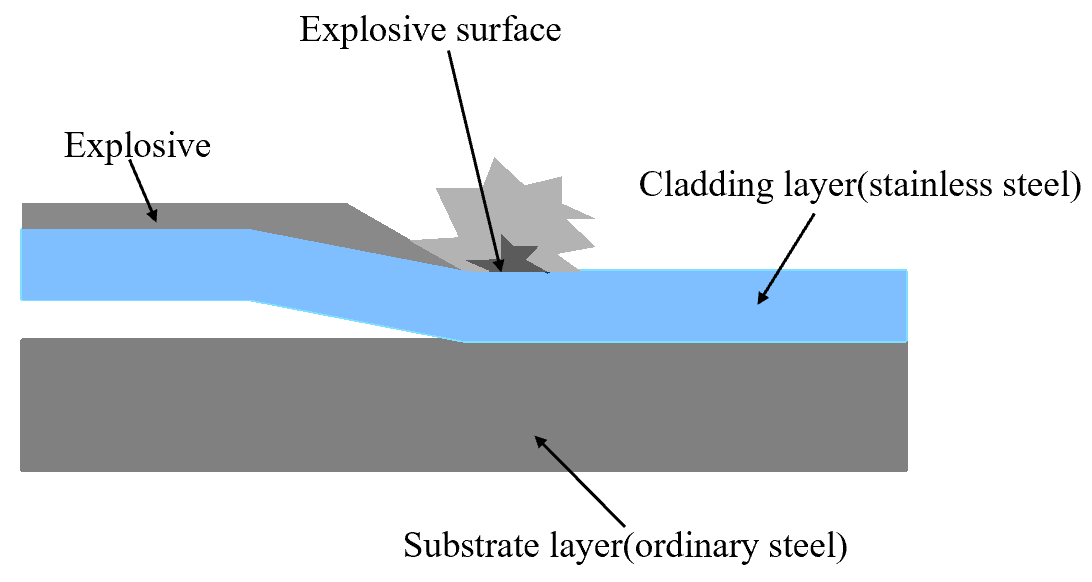

Research on stainless-clad bimetallic steel can be traced back to the 1930s, and the United States, Japan, the United Kingdom and the former Soviet Union took the lead, while China launched a stainless-clad bimetallic steel research in the 1960s. With the continuous development of the production process of stainless-clad bimetallic steel, rolling compound method and explosive compound method have become the mainstream production methods of stainless-clad bimetallic steel, as shown in Figure 2 [5].

Figure 2. Main production process of stainless-clad bimetallic steel. (a) Rolling compounding; (b) Explosive compounding.

Rolling compounding can be divided into hot rolling compounding and cold rolling compounding. Hot-rolling compounding method refers to a method of increasing the activation energy of the material through high temperature, so that it can be combined under lower pressure, which is suitable for materials with high strength and low plasticity. Moreover, cold rolling method is a method to compound the material at a lower temperature by applying a larger rolling force to the material, which is suitable for materials with low strength and high plasticity. According to the finishing and summary of the existing production process of composite materials, the rolling compound process can be divided into three processes. First of all, the surface treatment of the cladding layer and the substrate layer is carried out, that is, the impurities on the surface of the material that may affect the composite are removed, and then the four sides of substrate layer and cladding layer are welded and sealed to prevent interface oxidation [1]. In addition, the substrate layer and cladding layer are rolled. In this process, the surface of the metal to be compounded is broken and new metal is exposed by applying pressure, resulting in large plastic deformation and composite metal materials [8]. Finally, the heat treatment of the composite material after rolling reduces the internal residual stress of the stainless-clad bimetallic steel, increases the material resistance, and avoids the macro-warping of stainless-clad bimetallic steel to increase the bonding strength [9, 10].

Explosive compound method refers to the technology that the cladding layer and substrate layer of stainless-clad bimetallic steel produce high pressure and high strain in turn at the contact point under the action of explosive to combine the interface. The advantage of explosive compound method is that the high pressure generated by explosion can combine the cladding layer and substrate layer, and the equipment is simple and the cost is low. Besides, the interface is thin corrugated, the shear strength is high, the element diffusion range is small, and the thickness of each layer basically does not change before and after composite [5]. The explosive compounding method also has very serious problems, such as the high demand of the thickness of plate, thin plate is easy to penetrate in the composite process, and thick plate will lead to insufficient penetration of the explosion and poor composite quality. In addition, the explosive compound method also has high requirements for the number of explosives, and the noise and various harmful gases generated during the explosion will also have an impact on the surrounding environment.

2.2. Welding process

The introduction of stainless-clad bimetallic steel welding technology in China was first learned in Japan, which mainly studied the rules and standards of welding construction, preparation for welding construction, welding sequence and selection of welding materials [11]. The welding preparation sequence of stainless-clad bimetallic steel is heating treatment, cutting, groove treatment, forming. Now, new welding processes related to stainless-clad bimetallic steel are emerging in an endless stream, such as basic submerged arc welding and electrode arc welding, etc. Among them, electrode arc welding with high welding speed, good quality and low cost is the most widely used [12].

3. Research on material mechanical properties of stainless-clad bimetallic steel

3.1. Corrosion resistance

Excellent corrosion resistance is one of the significant criteria to evaluate whether the material is suitable for engineering applications. In addition, the corrosion resistance of stainless-clad bimetallic steel will be significantly improved compared with carbon steel, so it has more obvious engineering application advantages.

In recent years, many scholars have done more detailed research on the corrosion resistance of stainless-clad bimetallic steel. Among them, Li [13] selected Q235 carbon steel as the substrate layer and 304 stainless-steel as the cladding layer. They adopted the method of electrolytic accelerated corrosion test to explore the corrosion of composite materials in different environments. At last, the research results showed that the corrosion resistance of composite materials in mudstone soil, sandy soil and loess environment was good. However, when the material is in the saline soil environment, due to the high chloride content in the environment, the pitting corrosion of the composite material is easy to occur. Some scholars also studied the corrosion resistance of composite materials in acidic soil environment, and simulated the corrosion environment of 304+Q235 composite materials by means of electrochemical corrosion and chemical immersion [14]. It was found that the multilayer stainless steel did not suffer corrosion, while the corrosion of carbon steel base layer was extremely serious. Wang [15] studied the intergranular corrosion behavior of composite plates after heat treatment, mainly using the experimental method of oxalic acid corrosion, and conducted a detailed exploration of the intergranular corrosion characteristics of 304, 321 and 316L stainless steels after heat treatment. The research results showed that: heat treatment makes an extraordinary difference to the corrosion resistance of 304 stainless steel, so it is necessary to strictly control the processing technology of composite materials to strengthen the corrosion resistance of the material.

3.2. Composite interface performance

The property of composite interface is one of the most characteristic mechanical properties of stainless-clad bimetallic steel, and many scholars have studied its properties. Zhen [16] studied the effect of deformation rate on the composite interface results and bonding properties of 316L+Q420 stainless-clad bimetallic steel, and used a thermal simulation testing machine to conduct thermal simulation compression tests of composite splines with different deformation rates. In addition, the microstructure of the composite interface, element diffusion behavior of the composite plate interface, hardness of the composite plate interface and tensile binding properties of the composite plate are summarized. In the end, the research results show that: composite interface is composed of three layers: decarburization layer, interfacial transition layer and carburizing layer. With the increase of deformation rate, the thickness of decarburization layer Narrows, the grain is refined, the thickness of the diffusion layer of Cr, Ni and C elements decreases, and the hardness of different layers also changes when the deformation rate is in different stages. Some scholars have explored in depth the influence of hot rolling process on the interface structure of 304 stainless steel +Q235 carbon steel stainless-clad bimetallic steel [17]. After analyzing the phase analysis, interface element diffusion, interface fiber structure characteristics, grain refinement and recrystallization distribution of stainless-clad bimetallic steel through experiments, it is found that: The interfacial structure of Q235 carbon steel+304 stainless steel hot-rolled composite is composed of 304 layers of austenite and Q235 layers of ferrite and pearlite. A diffusion layer of Fe, Cr, Ni, Mn and other elements appeared at the interface of the composite, and the grains of the composite were obviously refined after secondary hot rolling.

4. Conclusion

Stainless-clad bimetallic steel has the dual advantages of high performance and low cost, with the science and technology advances in China and the upgrading of industrial functions, stainless-clad bimetallic steel is gradually showing its advantages in construction projects. stainless-clad bimetallic steel not only has the advantages of stainless-steel materials, but also the lower production cost makes it have a very significant market advantage, so in-depth research on stainless-clad bimetallic steel has important economic significance, social significance and strategic value.

This paper mainly summarizes the production process, welding process, corrosion resistance and composite interface properties of stainless-clad bimetallic steel. It can be found that the current production and manufacturing process of composite materials and mechanical properties of materials have been more in-depth research. However, at present, there are fewer studies on the application of stainless-clad bimetallic steel in structural members. Now, composite stainless steel is more used in the actual engineering maintenance system rather than the structural system of the building, The reason contributing to this phenomenon is officially due to the less research on the application of stainless-clad bimetallic steel in structural members. Therefore, under the premise that the manufacturing process and material properties of such excellent composite steel are fully studied, it is urgent to focus on the application of it in structural components such as beams and columns.