1. Introduction

The turbine engine is an internal combustion engine that uses rotating parts to absorb kinetic energy from the fluid passing through it. It is commonly used as an engine for aircraft and large ships or vehicles. All turbine engines have three major components: a compressor, a combustion chamber, and a turbine, which is why the engine is named [1]. The simplest turbine type can have just one "Rotor" like a fan blade with a center axis, even though a turbine engine may have many distinct working principles. Axial torque is produced from the center shaft when the fluid goes through because the force on the fan blade causes the complete rotor to spin. The oldest human-made turbine engine prototypes are ancient machines like windmills and water engines. The most significant advantage of turbo engines is that they can significantly increase their power without increasing the engine displacement. Non-turbocharged engines directly absorb air from the atmosphere through the movement of the crankshaft, while turbocharged engines provide compressed air to the engine through turbochargers. According to different classification methods, turbine engines can be roughly classified into these four forms: Turbofan, Turbojet, Turboprop, and Ramjet engines.

The bypass air and jet core efflux technologies are combined to provide thrust by the turbofan engine, a type of enhanced jet engine. The words "turbine" and "fan" make up the phrase "turbofan." The "turbine" section represents a gas turbine that generates mechanical power through combustion, and the "fan" section represents a ducted fan that accelerates backward air using the mechanical power of the gas turbine [2]. A turbojet, the name given to a gas turbine engine, is designed to generate thrust by ejecting gas at high speeds from the back of the engine through a suitably shaped propulsion nozzle. It is characterized by its reliance on the gas stream to generate thrust. Commonly used in high-speed power aircraft but with higher fuel consumption than turbofan engines.

2. Turbofan engines

A turbofan engine is made up of a fan, two compressors, a combustion chamber, two turbines to power the fan, a nozzle, a shaft, and an exhaust system. The low-pressure compressor is unique to the high bypass ratio turbofan. The core engine combines the high-pressure compressor, combustion chamber, and high-pressure turbine. The low-pressure turbine-driven fan receives some energy from the core engine's exhaust gas, and the nozzle uses the remaining energy to accelerate the gas. The air splits into two paths as it goes through the fan. Internal airflow is one. The compressor keeps compressing the air, mixed with fuel, in the combustion chamber. To generate thrust, the tail nozzle releases gas at a high rate. External culvert flow is the additional option. The air behind the fan is straightforwardly released into the climate through the outside duct, spout, and inward gas. Three main types of turbofan engines are medium or afterburning, high-bypass, and low-bypass [2].

2.1. Low-bypass engine

Jet thrusting rather than fan thrusting is used in this engine. To achieve maximum efficiency, for the fighter to soar quicker than the speed of sound, the air entering the engine needs to move more slowly than sound. A multistage fan in a low-bypass turbofan engine generates a relatively high-pressure ratio, resulting in a faster exhaust velocity. The core's airflow must be sufficiently large for the fan to function. When compared to standard turbojets, these kinds of engines use less fuel. With afterburners, most of the most recent fighters use low bypass ratio turbofans. After that, they can fly well and have sufficient combat power.

2.2. Medium or afterburning engine

The primary function of an afterburner is to boost the thrust required for supersonic flight. "Reheated" exhaust gas is produced when additional fuel is injected into the combustion chamber via an injection pipe downstream of the turbine following combustion. Instead of utilizing a larger engine, it can significantly increase thrust by reducing weight. Because this motor requires a ton of fuel, its utilization time is short.

2.3. High-bypass engine

It is an engine whose fundamentals oppose those of a low-bypass engine. Nearly all passenger and military aircraft now use turbofan engines with a high bypass ratio to reduce noise and improve fuel efficiency. The engine can maintain a low constant thrust by switching from multistage to single-stage fans. Some civil turbofan engines do not have fixed inlet guide vanes in front of the fan rotor like military engines do. The fan must operate at the required pressure ratio and flow for the engine's core to produce sufficient energy. The improvement of turbine material expands the delta temperature of the high-strain turbine rotor, consequently expanding the intensity yield of the center.

3. Turbojet engines

There are two types of turbojets: centrifugal and axial. The centrifugal was invented by Sir Frank Whittle, an Englishman, in 1930, but it was not until 1941 that an aircraft equipped with such an engine flew in the air for the first time, nor did it participate in World War II. The axial flow was born in Germany and entered the field in the summer of 1944 as the power for the Me-262, the first practical jet fighter. Compared with a centrifugal turbojet, the axial flow has the advantages of a small cross-section and high compression ratio, and most of today's turbojet engines are axial flow.

3.1. Working principle

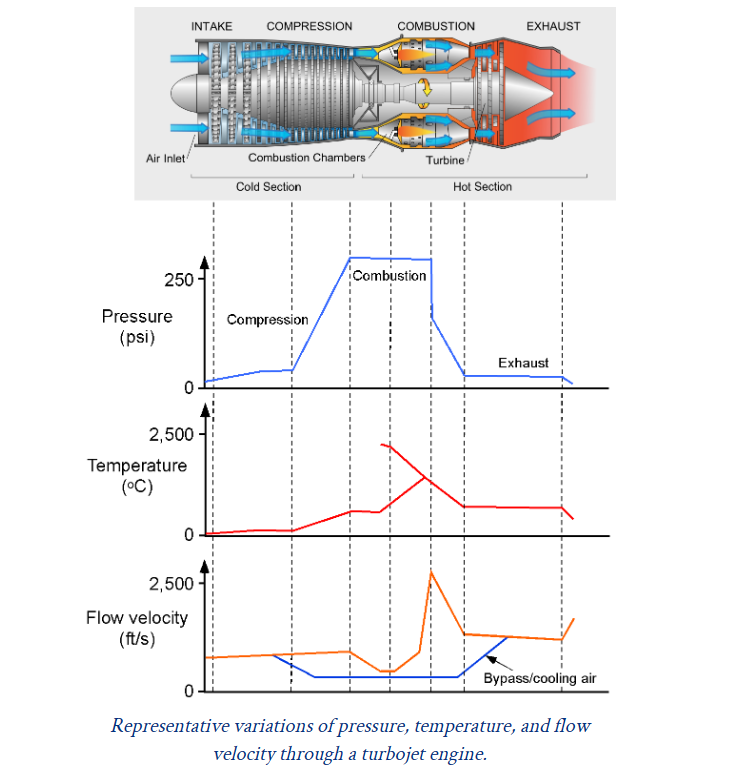

Figure 1 shows the principle of operating a turbojet engine. The Brayton cycle is the base of the thermodynamic operation of the turbojet [3].

Figure 1. The principle of operating a turbojet engine [3].

Modern turbojets have the following components: an intake, a compressor, a combustion chamber, a turbine, and a tail nozzle. An afterburner is located between the turbine and the tail nozzle on a fighter jet. A turbojet must adhere to the idea that heat accomplishes the work since it is still a heat engine: it takes in energy at high pressure and lets it out under low pressure. Hence, jet engines and piston engines are equivalent in terms of the creation of output energy. They must include the four stages of intake, pressure, combustion, and exhaust. The four operational positions of a piston engine's four stages are timed in succession in contrast to the jet engine's continuous gas flow through every component, corresponding to the piston engine's four operating stages.

3.2. Application status

Turbojet is suitable for a wide range of navigation, from low altitude low subsonic to high altitude supersonic aircraft are widely used. A turbojet engine from the Rurika Design Bureau propels the famed Mig-25 high-altitude supersonic fighter jet of the former Soviet Union. It has established records for fighter speed (Mach 3.3) and ceiling (37,250 meters). Although the turbojet engine has a poorer fuel efficiency than the turbofan, it performs better at high speeds, especially at altitude. While jet engines consume more fuel than piston engines at low speeds, their superior high-speed performance causes them to displace the latter soon and take over as the primary aviation engine.

3.3. Future outlook

For 60 years, jet engines have remained relatively unchanged: sucking in air, squeezing it, heating it, and venting it. The last three steps - compression, combustion and exhaust - make up the engine core or power chamber. Today's engines are fine-tuned machines, but more can be done to improve efficiency. Shocking the core increases the engine bypass ratio, meaning the fuel burn rate changes only slightly by adding a larger intake fan [4].

4. Turboprop engines

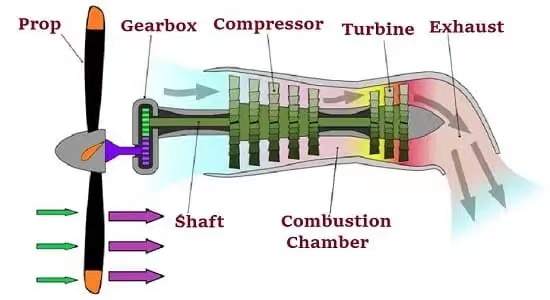

A jet engine with a rotating propeller and jet power is called a turboprop engine. It functions similarly to a turbojet engine. On the other hand, the turboprop engine has an additional propeller in front of the engine and another turbine behind the combustion chamber. This propeller is attached to the shaft and is operated by a speed control gear. The engine is mostly used for short travels or slow cruising speeds.

Figure 2. Structure of turboprop engine [5].

Air from the atmosphere is first drawn into the engine's compressor. Turbofan engines use centrifugal compressors to compress air. The compressor raises the temperature and pressure of the air as it receives it. The compressor is then brought to the combustion chamber once the air has been compressed as needed. The fuel injector injects fuel into the combustion chamber when compressed air enters it, mixing it with the air.

The fuel-air combination ignites independently due to the air's intense compression. The air-fuel mixture's temperature and internal energy are raised during ignition [6]. After burning, the fuel-air combination is delivered to the larger turbine area, where it continues to burn. The turbine blades use the greatest amount of the air-fuel mixture's power to drive the compressor when it strikes them at high speed, while only a little exhaust energy is released into the atmosphere. The compressor further propels the engine's propeller after receiving energy from the turbine (Figure 2). The engine propeller's rotation produces thrust, which propels the aircraft forward. Air intakes, compressors, diffusers, combustion chambers, turbines, reduction gearboxes, and propellers are all parts of turboprop engines [7,8].

5. Ramjet engines

5.1. The principle of ramjet engines

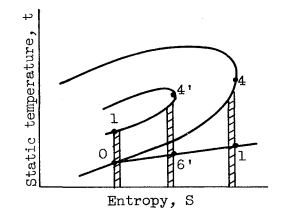

Ramjet engines are a kind of jet engine. But unlike turbojet engines and their variants, ramjet engines use shock waves to complete the compression process instead of the turbine to compress the air entered from the inlet. The general cycle of the ramjet engine is called the supersonic-compressed ramjet cycle (or the SCRJ cycle) [9]. The cycle includes these processes (Figure 3): 1-4’ is the compression and heating process. The air first enters the diffuser for first-stage deceleration; the shock waves provided by the engine's inlet will decelerate the air further. In this process, the ramjet engines will decelerate the flow to subsonic velocity while the scramjets will not. The shock waves will also provide pressure for the compression process. After that, the air enters the combustion chamber and starts to burn, regarded as a heating process (process 3-4). Point 4’ represents the condition of the highest temperature and entropy. Process 4’-6’ is the isentropic expansion process, providing thrust for the engine, and 6’-0 is the process of exhausted gas returning to the initial condition, completing the cycle.

Figure 3. T-s diagram of the SCRJ cycle [9].

5.2. Features of ramjet engines

As the author said above, the ramjet engine needs shock waves to provide pressure, which means they need a supersonic reservoir. And also, because of that, ramjet engines have no compressors to compress the air, while they do not need turbines to provide work for the compressor. Though the working cycle of ramjets has different turbojet engines’, they all use the high velocity exhausted gas from the nozzle to develop thrust, so their propulsive efficiencies can use the same method to calculate:

\( {η_{p}}=\frac{{\dot{W}_{p}}}{{\dot{Q}_{in}}} \) (1)

While the effective work output by the exhausted gas flow

\( {\dot{W}_{p}}= \dot{m}({v_{ex}}-{v_{in}}){v_{aircraft}} \) (2)

Airflow velocity at the nozzle exit is represented by \( {v_{ex}} \) , whereas airflow velocity at the inlet is represented by \( {v_{in}} \) . The ramjet engines also have no flame holders, which means the propulsion forces of ramjets cannot be controlled [10]. This important feature limited the application fields of the ramjet engines to a large extent.

5.3. Applications of ramjet engines

In the previous section, the author discussed the features of ramjet engines and concluded that ramjet engines could only work in supersonic airspeed, which resulted in the need for another propulsion unit to provide thrust in subsonic acceleration, usually turbojet engines or rocket engines, a few are carried by other aircraft to reach sonic speed (or provide conditions to reach supersonic airspeed). The author will show some examples of ramjets’ applications.

5.3.1. RIM-8. The RIM-8 missile uses a rocket engine as the propulsion unit for acceleration. It has an inlet cone to control the shock wave at the inlet, and it uses oblique shock waves to decelerate the airflow at the diffuser. This design can improve the air intake efficiency at supersonic airspeed. Also, because of the ramjet engine, RIM-8 has a longer operational range than missiles using rocket engines in the same era.

5.3.2. Nord 1500. The propulsion unit of Nord 1500 is a ramjet-turbojet combination. The turbojet will provide thrust in subsonic conditions, and the ramjet will work in supersonic conditions [10]. Unlike the RIM-8, Nord 1500 uses a pitot inlet, which means no inlet cone. That will cause the shock waves in front of the inlet to be normal rather than oblique. This design will increase the resistance and reduce air intake efficiency while the pressure will increase.

6. Conclusion

All turbo engines use airflow as the working medium and have similar thermodynamic cycles. But different variants of turbo engines have different working principles, which causes their different features and working atmospheres. The turbojet engines can develop thrusts under most conditions, but the compressor part limits the efficiency. These engines’ efficiencies can improve by using computer monitoring systems and re-designing the inlet. The turbofan engine is more efficient comparing turbojet engines, but also ineffective under high-altitude conditions. These engines will still be mounted on small aircraft working in low altitudes and can improve performances by applying the variable-blades technology. The turboprop ones have better fuel efficiencies than the turbojets, though the propellers' disadvantages are the same as the turbofan engines. The application fields of this variant will be more likely in heavy aircraft with long operational ranges, and the efficiencies can be increased by applying better control systems. Ramjet engines are more efficient in high-speed conditions but unavailable at low-speed. The performance can be improved by changing the fuel type or improving the design of the inlets. As a result, the engine generates more thrust with roughly the same amount of fuel burned, making it more efficient. Higher fuel efficiency is the ultimate goal, lowering costs and emissions. In the future, people are supposed to significantly reduce engine cores' size to improve fuel consumption without compromising maneuverability, durability and performance. Taking together, the future application fields of turbo engines will still be aircraft engines.