1. Introduction

Cars are becoming more and more important in people's lives, and various manufacturers have made many innovations in the transmission system of cars, and how to make it more efficient and easy to use is a problem we need to consider and solve. In order to study the improvement direction of three types of transmissions (MT, AT and CVT), this paper, starting from the structure and principles of transmissions, will analyze the advantages and disadvantages of transmissions to find out the areas of improvement. The paper can also be a reference for readers who are interested in automotive and industrial research and need to study the mechanical structure of transmission.

2. Transmission overview

2.1. Functions

The main function of the transmission is to automatically or manually select different gears to drive according to different driving conditions, for example, in the starting or uphill section, the transmission can cut into a lower gear to provide the car with more torque, while on flat roads such as highways, it can cut into a higher gear to provide the vehicle with higher speed [1].

2.2. Transmission ratio

One of the most basic points of knowledge about transmissions is the transmission ratio, also known as the gear ratio. The principle of transmission gearing is that two or more gears of different sizes are driven to change the speed of the output shaft, as well as the torque. When a large gear with a small gear, the speed becomes larger, but his force becomes smaller. On the contrary, when a small gear takes a large gear, the speed becomes smaller, but the force becomes larger [2].

Gear transmission follows: Large with small, low torque, high speed; Small with large, high torque, fast speed.

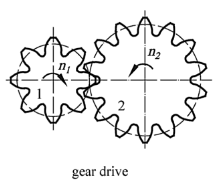

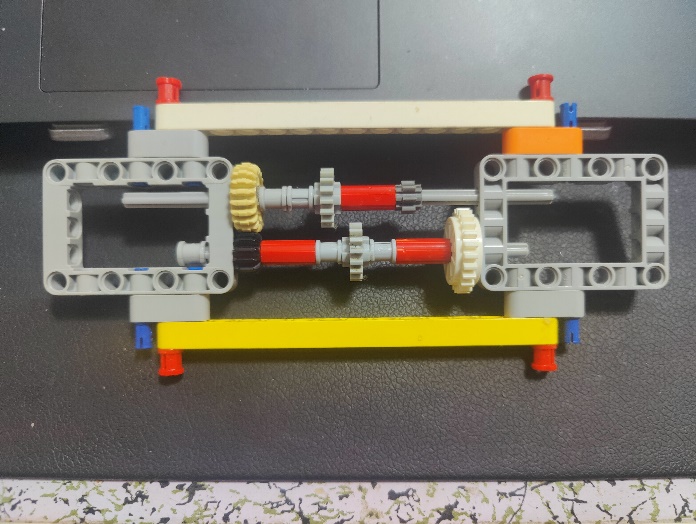

Figure 1. 14-tooth gear (right) drives 8-tooth gear (left) [3].

Two gears are used here for explanation (as shown in figure 1), a 14-tooth gear A (right) and an 8-tooth gear B (left) for demonstration.

Torque formula is: ι=Z1/Z2=n1/n2=s2/s1 [4]

Where, ι: Gear ratio, Z: Number of teeth, n: Torque, s: Speed

If we put the power input shaft on the left gear, the speed (s1) is 1 rps, and the torque (n1) is 1Nm, through the number of teeth of the two gears, the transmission ratio from left to right can be calculated as 8÷14= 0.57, it can be obtained by calculation that the speed of the right gear is S2=S1 x ι =1 x 0.57 =0.57rps, and the torque is N2=N1÷ ι=1÷0.57=1.75nm.

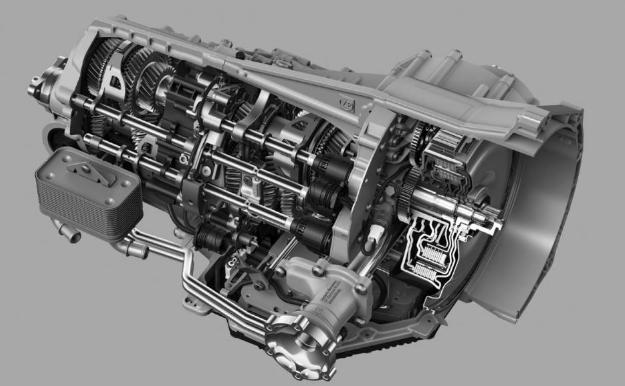

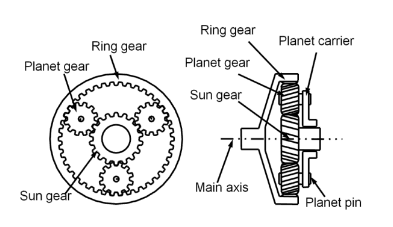

Here is the basic gear ratio, and the automotive gearbox (figure 2), through multiple complex gear sets to switch different ratios, realizes the gearbox to switch different speed gears of the car, so as to change the speed of the car.

Figure 2. Hyundai gearbox internal structure diagram [5].

2.3. Reason for gears shift

Before we start introducing AT, MT and CVT, it is needed to understand why cars need to shift gears.

The biggest role of the transmission is to switch different gear ratios through multiple sets of gears to match different driving sections. For example, uphill sections, have higher requirements for torque output, so the transmission should be in a lower gear, using the aforementioned small with large to increase torque. While if the driving situation is out of high speed, you need to switch to a higher gear, using the large with small gear ratio to provide a larger speed.

The torque range of a fuel car engine is relatively small, and without the help of a transmission, it is somewhat overwhelming in scenarios such as starting, going up hills, driving at high speeds, and backing up. Let's take an example of a bicycle around us, a variable speed bicycle, which has two parts of gears, the active gears of the foot pegs and the driven gears of the coaxial rear wheel. When we ride uphill, in order to save energy, we will use the small active gear + large driven gear, pedal faster, to (active wheel) high speed for (driven wheel) high torque, so as to achieve easy uphill. When the bike is on a flat road and the speed is up, we will use the large active gear + small driven gear, pedal harder and slower, and exchange the high torque (of the active wheel) for the high speed (of the driven wheel) to achieve a faster driving speed. The gearbox principle of a car is similar to that of a bicycle, using gears to switch back and forth to adapt to different driving conditions.

3. Manual transmission

3.1. The concept of MT

The common transmissions on the market can be roughly divided into two categories, namely manual transmissions (MT) and automatic transmissions (AT). The author will first discuss the manual transmission.

Most manual transmissions for cars are four or five gears stepped gear transmission, and usually with synchronizers, easy shifting, low noise, but manual transmission in the manipulation of the gear shift must be depressed clutch, in order to dial the gearshift. Manual transmission is the opposite of automatic transmission. In fact, before the emergence of automatic transmission, all cars are using dynamic transmission. Manual transmissions use gears of different sizes to change gears. The most common manual transmissions are mostly 6-speed (5 forward gears, 1 reverse gear), and some cars use 7-speed (6 forward gears, 1 reverse gear) transmissions. Generally speaking, the transmission efficiency of the manual transmission is higher than that of the automatic transmission, so the driver's skill is good. Manual transmission cars are faster and more fuel efficient than automatic transmission cars when accelerating and overtaking.

3.2. The principle of MT transmission

To better understand the MT gearbox, here is a simple explanation of three-speed shift mechanics.

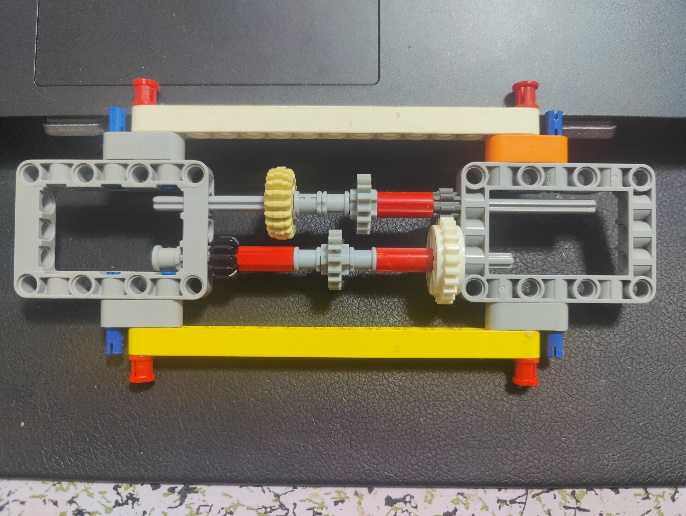

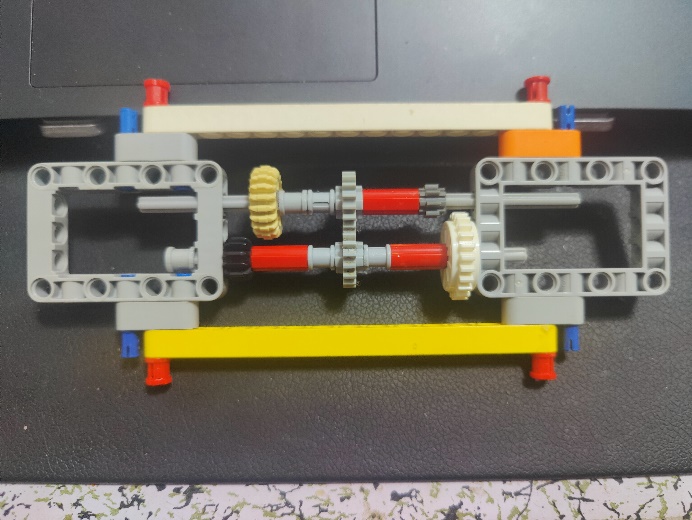

Figure 3. MT gearbox in 1st gear driven by 8 gears with 24 gears.

As shown in Figure 3, here we set the upper shaft as our power input shaft and the lower shaft as the output shaft.

Now the gearbox is in the first gear, the input shaft gear size is 8 teeth, the output shaft gear size is 24 teeth, the gear ratio is 3. At this time, the gearbox can provide strong torque, but lower speed, this situation is suitable for the car start acceleration or uphill driving situation.

Figure 4. MT gearbox in 2nd gear driven by 16 tooth gears.

After the start, our vehicle’s driving no longer needs so high torque, and needs a moderate speed. Then you can cut into the second gear. As shown in Figure 4, here in the model of the second gear is a two 16-size teeth gear, then the tooth ratio is 1. Do not change the speed or change the torque; provide the vehicle with a balance of torque and speed.

Figure 5. MT gearbox in 3rd gear with 20 gears driving 12 gears.

Suppose the vehicle on the highway needs to increase its speed, then you need to cut into third gear. As shown in Figure 5, here the power input shaft gear is a 20-tooth gear, and the output shaft gear is 12 teeth. By calculating the gear ratio is 0.6, the transmission can provide a higher speed to adapt to high-speed driving conditions [6].

(All gear ratios and data is this part are only for the explanation of the principle of manual transmission, in the reality of the car gear ratio is generally greater than 1, through multiple sets of gears to achieve different gear ratios. The larger the gear ratio, the greater the speed; the smaller the gear ratio, the smaller the speed.

3.3. Advantages and disadvantages of MT gearboxes

The advantages of MT transmission are that it can give the driver a free driving experience; the transmission efficiency is higher than that of an automatic transmission; it saves fuel, due to the simple structure and mature manufacturing process, so it is easy to repair and maintain; and the manufacturing cost is low. However, the disadvantage of this type of transmission is also obvious, the operation needs to cooperate with the clutch in order to complete the shift operation, which is not an easy task for unskilled drivers and can easily damage the transmission and engine.

4. Automatic transmission

4.1. The concept of AT

Automatic transmission (AT), is also known as automatic gear. Automatic transmission consists of: a hydraulic torque converter, a planetary gear transmission, and a control mechanism. Automatic transmission has the advantages of easy operation, comfortable driving, and reducing driver fatigue, becoming a modern car configuration of a development direction. Cars equipped with automatic transmissions can automatically shift torque according to road conditions, so the driver can pay full attention to the road traffic and will not be shifting gears to get busy.

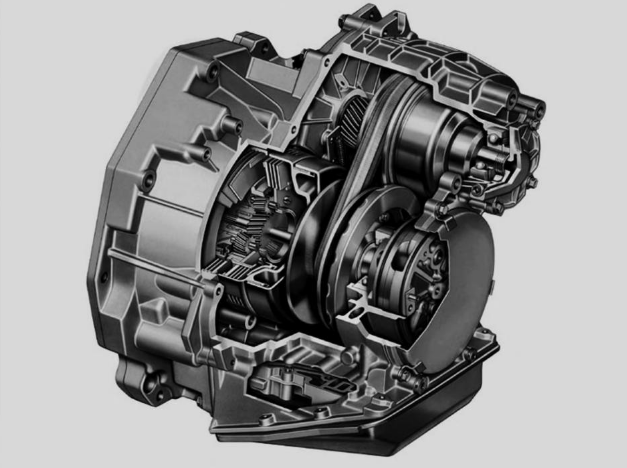

There are three common types of automatic transmissions: hydraulic automatic transmission (AT), mechanical continuously variable automatic transmission (CVT), electronically controlled mechanical automatic transmission (AMT). AT is commonly used in cars, and AT has almost become synonymous with automatic transmission. AT is composed of a hydraulic torque converter, a planetary gear and a hydraulic manipulation system. Through the hydraulic transmission and gear combination, it achieves variable speed torque. The hydraulic torque converter is the most important component of AT, which consists of a pump wheel, turbine and guide wheel and other components, and has the role of transmitting torque and clutching [7].

4.2. The principle of AT

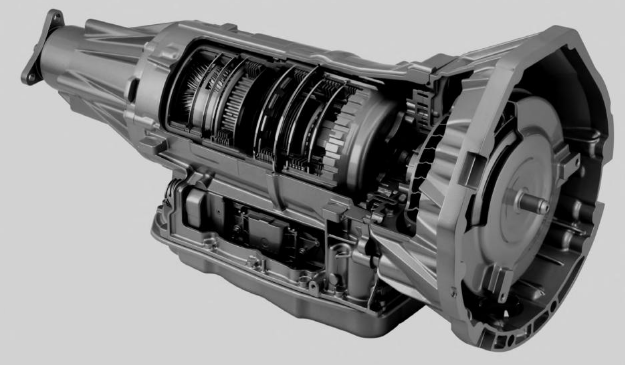

Figure 6. AT gearbox single set of gears diagram [5].

Figure 7. The complete AT transmission consists of multiple sets of gears [5].

Figure 6 is one of the gear sets of the AT transmission, and this set of gears can be divided into three types of gears, namely the sun gear, the planetary gear, and the ring gear.

The input shaft is on the sun wheel, and when the sun wheel starts to rotate, the gearbox will start to work and the following situations will occur.

In the first gear of the driving state, the outermost ring wheel is fixed. Assuming that the sun wheel is rotating clockwise, the single planetary gear will rotate counter clock wise, but since the ring wheel is fixed, the three planetary gears will rotate clockwise if considered as a whole, and then we will output the rotation of these three planetary gears to a shaft, and we have the output shaft.

The essence of the AT gearbox shift is to change the rotation speed and direction of the ring wheel. If the ring wheel rotates in the same direction as the sun wheel, the sun wheel rotation speed remains the same, the faster the ring wheel rotation speed is, the faster the planetary gear set rotation speed is, and the faster the output shaft rotation speed is.

If the ring wheel and the sun wheel rotate in opposite directions, the sun wheel speed remains unchanged, the ring wheel speed is faster, the planetary gear set speed is slower, and the output shaft speed is slower. But when the ring wheel speed exceeds the sun wheel speed, the planetary gear will rotate in the opposite direction, and the output shaft will rotate in the opposite direction, and the reverse gear will be realized [8].

Then how to change the ring wheel speed to achieve the gear change operation?

This way we can add another set of gears to the original set of gears, so that the gears of the latter set are connected to the ring wheel of the former set (as shown in Figure 7). In the first gear, we lock the ring wheel of the first group of gears and let the sun wheel of the first group drive the planetary gear directly. When we move up to the second gear, we can unlock the ring wheel of the first group, lock the ring wheel of the second group, let the sun wheel of the second group drive the planetary gear and then drive the ring wheel of the first group, let the ring wheel of the first group change its speed so as to change the speed of the planetary gear of the first group, thus realizing the switching of the first and second gears.

4.3. Advantages and disadvantages of AT transmissions

The advantage of the AT transmission is that it is simple and easy to operate, does not require clutch access to shift gears, which guarantees driving efficiency in complex driving situations in the city, and has a simpler structure and smaller size than the MT transmission. However, the disadvantage is that the driving is not as smooth as MT transmission, and the vehicle cannot be controlled comfortably under complicated driving requirements.

5. Continuous variable transmission

5.1. The concept of CVT

CVT is continuous variable transmission. As the name suggests, there is no specific gear, and the operation is similar to automatic transmission. The speed ratio change is different from the automatic transmission jumping gear process, but continuous, so the power transmission is continuous and smooth [9].

5.2. Principle of CVT Transmission

The CVT has no gears and relies on a steel belt drive. To achieve variable speed, you need to change the diameter of the re-end of the steel belt.

Figure 8. The inside of the CVT gearbox is driven by a steel belt [5].

As shown in figure 8, two cone pulleys are in contact with the steel belt. When the two cone pulleys are close together, they squeeze the steel belt, but since the steel belt is hard and does not deform, it shifts with the squeeze, thus expanding the diameter in contact with the cone pulleys, which changes the gear ratio [10].

Since the length of the steel belt is limited, if the contact diameter is increased by changing on one side, the other side needs to be separated by the cone wheel to reduce the contact diameter so that the speed can be changed properly with the limited length of the steel belt.

5.3. Advantages and disadvantages of CVT transmissions

CVT transmission has the advantage of non-gear transmission, providing a smooth and stable shifting experience. This transmission structure can also be more fuel-efficient, while giving the driver the freedom to set the gears. But due to the special transmission structure, resulting in this type of transmission cannot drive high intensity power, but also brings a higher failure rate.

6. Comparison of the three transmissions

After the above analysis of advantages and disadvantages and principles, the CVT transmission is the best in vehicles with less power because it can provide the most comfortable and smooth driving experience, but due to the limitations of material technology, it cannot be used in high power vehicles. The AT and MT transmissions do not have any objective advantages or disadvantages, depending on the driver's operating habits, so you can choose the AT if you want to save time and get started, or you can choose the MT transmission if you want to have full control of the vehicle. Personally, I think that if the driver's driving situation is generally in the city, using an AT transmission will provide a better driving experience than an MT transmission [11].

7. Conclusion

AT, MT and CVT are all common and excellent types of transmissions in real life, AT automatic transmission saves driving energy and makes driving easy, but does not allow free control of the vehicle’s state. The CVT gives the vehicle the smoothest shifting experience, but its special structure limits the maximum amount of power it can handle.

Future improvements to AT transmissions can be made from an intelligent and customizable perspective, allowing drivers to set shift conditions according to their own driving habits, making the transmission more user-friendly and tailored to the driver's operating habits.

The future CVT can think in terms of materials and use stronger materials to make steel belts to increase the upper limit of the transmission's power capacity.