1. Introduction

Many individuals suffer from the dual challenges of being both blind and deaf. According to the National Center for Deafness and Blindness (NCDB), 1 in 10,000 children in the United States is diagnosed with deaf-blindness [1]. Communication is a significant obstacle for them, so researchers have developed a mobile device designed to enhance their interactions. This innovative product, called "Voidy," combines three cutting-edge technologies: 3D printing, sensor conduction, and artificial intelligence algorithms to facilitate easier communication between deaf-blind individuals. The Voidy device resembles an iPad in appearance and features two built-in communication systems. One system displays words on a secondary screen, while the other system employs sensors on the main screen to translate Braille into English [2]. This groundbreaking solution aims to improve the lives of the deaf-blind community by offering them a more accessible and efficient way to communicate with one another.

1.1. Materials

Now many mobile phone cases are 3d printed, and the case of this product can also be made by 3d printer. First of all, 3d printed materials are environmentally friendly. The materials used in the production need to be fall-proof, because they are blind, so the product is more likely to fall to the ground. So the material needs to be strong and light [3]. Authors think powder can be used. The size distribution of individual powder particles affects the way the powder is compacted and affects the density of the part and the likelihood of defects. Currently, 3D printing technology is developing rapidly and various technologies are emerging. They can be divided into six main categories, namely extrusion, wire forming, granulation, powder layer nozzles, lamination, and photopolymerization. As shown in figure 1.

Figure 1. Braille.

1.2. Advantages

3d printing is relatively cheap. Generally speaking, disabled people don't have a high income, so the price is also an important factor. It also has the advantage of diversifying products without increasing costs. A 3D printer can make objects in many shapes, one shape at a time, like a craftsman. In contrast, conventionally manufactured devices have fewer features and are limited in the shapes that can be made. In addition, 3D printing can save traditional manufacturing industries the cost of training workers and buying new equipment [4]. 3D printers just need new digital blueprints and new raw materials to make new objects. The second is that 3d printed items are lighter than conventional ones. Also, it can save time, even if broken also can be repaired in the fastest time, will not affect the life of these deaf mutes [5].

1.3. Function

3d printing can freely determine the shape of the product, and confidentiality is strong, can protect the user's privacy. others will not know that the user is deaf and dumb. It can also prevent the products from breaking the fall [6]. This product mainly includes Braille, but it would also be possible to import maps, which would make life easier for this group of people with disabilities.

1.4. Disadvantages

Although high-end industrial printing is possible for plastics, some metals or ceramics, nonprintable materials are expensive and scarce. Furthermore, printers have not matured to the point where they can support the broad range of everyday materials.

1.5. ABS plastic

ABS is a terpolymer of acrylonitrile, butadiene and styrene, where a represents acrylonitrile, B represents butadiene and S represents styrene [7]. ABS plastic is generally opaque, light ivory in appearance, non-toxic, odorless, with excellent impact strength, good dimensional stability, electrical properties, wear resistance, chemical resistance, dyeability, molding and processing performance is relatively good.

Figure 2. ABS plastic.

ABS plastic can be used for the outer shell of the product, as it is non-toxic, harmless and wear resistant. The material can also be used for a protective casing around the screen. Because plastic is an insulator, it won't hurt these disabled users. ABS plastic as a printing material, can be printed in the blind text Screen surface, and sensitively make judgments. Almost three layers of ABS plastic, each about 0.3mm thick, are needed to enable blind people to detect the braille pattern by touch. (More clearly). As shown in figure 2. Compared to the previous material, this one is more similar to him, but cheaper. To be more precise, abs plastic Paul is among the engineering plastics, so the first choice for the housing of this product is engineering plastic. As shown in figure 3.

Figure 3. Engineering plastics.

Compared to the previous material, this one is more similar to him, but cheaper. To be more precise, abs plastic is similar to the engineering plastics, so the first choice for the housing of this product is engineering plastic.

1.6. Composite gypsum powder

One of the most widely used materials in the field of 3D printing. Objects made of full-color sandstone have a strong sense of color. The surface of 3D printed products is grainy, and the printing pattern is more obvious, making the objects have special visual effects. It is brittle and easily damaged, making it unsuitable for printing objects that are often left outdoors or in extremely humid environments. Also, the engineering plastic has more varieties [7].

Because this material is easy to break, so it is not suitable for this product. If the disabled user group accidentally breaks the product, which will have very serious consequences. Not being able to keep it outside for long periods of time means it is very inconvenient.

1.7. Metallic materials

Metallic material refer to materials with luster, ductility, easy conduction, heat transfer and other properties. Generally divided into black metal and non-ferrous metal two [8]. As shown in figure 4. Ferrous metals include iron, chromium, manganese and so on.Inside the product, this material must be used. Because metals can conduct electricity, a current runs through both the chip and the structure inside [9].

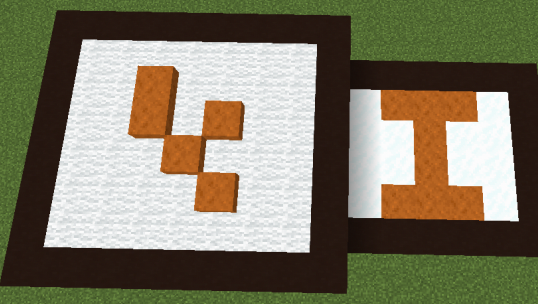

Figure 4. The appearance of the product, the main screen (right) and the sub screen (left).

2. Implement

2.1. Fused Deposition Modeling method

In the Fused Deposition Modeling (FDM) fused laminate forming technology, a filamentary hot melt material is heated and melted while a 3D nozzle, under computer control, selectively applies the material to the table according to the information from the slicing wheel and, after rapid cooling, forms a layer of slices. Once a layer is built, the machine table is lowered one level (layer thickness) to build the next layer until the whole solidified shape is built.

2.2. Why choose FDM technology.

Firstly, the working environment is clean and safe, the material is non-toxic and the process can be carried out in an indoor environment without the risk of producing toxic fumes and chemical contamination. In addition, there is no need for expensive components such as lasers, so it is cheap. Second, the raw material is in the form of coiled wire, which saves space and is easy to handle and replace. Finally, material utilisation is high, many alternative materials are available and the price is relatively low.

2.3. Disadvantages of FDM technology

Not only is the surface of the part rough when it is formed and needs to polish, but the maximum accuracy is only 0.1 mm and the speed is low because of the mechanical motion of the nozzle. There is a need for material as a support structure.

2.4. The process of implement:

2.4.1. Modeling. One of the most crucial steps is the CAD or CG model, which is also the most core part of the modeling software. Of course, finding the existing is not impossible, there are many 3D printing model sharing platform on the Internet, there are many beautiful models. In this product, it is needed to model it by yourselves.

2.4.2. Divide the target into small targets. After using the computer for three-dimensional modeling, the system needs to be divided into pieces, using segmentation and layering, segmentation, and then imported into the printer to print step by step. Common formats are STL file format and PLY file format. Can also use PLY. this is a file format high-resolution printer. Since this is a tool for people with service disabilities, it is not necessary to pull all configurations to the best. Normal STL is fine. The resolution of a 3D printer is sufficient for most applications (curved surfaces may have a rough surface, such as jagged teeth on a picture), and a higher resolution object is obtained by first producing a slightly larger object with the current 3D printer and then lightly polish the surface to obtain a "high resolution" object with a smooth surface The "high resolution" object is obtained by first producing a slightly larger object with the current 3D printer and then lightly polish the surface to obtain a smooth surface.

2.4.3. Data Import. Once the model is designed, simply use a USB drive or data cable to input it into the 3D printer and then set it up for printing. Once set up, run the 3D printer and you can print it out directly. After layer by layer design, a beautiful set of models will be printed out and can be directly used for manufacturing even in advanced material applications. Just import the model of the shape of an ipad.

2.4.4. Surface polishing. After printing, there are still some masses that are not too high resolution and may be a little uneven when printed out. In order to get a high resolution model, first print out a larger size model with 3D printer and then polish its surface so as to get a higher resolution model. Zongwei Cube provides users with complete 3D printing application solutions, guiding them to quickly understand the characteristics of the product and how to use the product, and easily get started to experience the function and creativity of the product. A smooth product surface provides a better feel, while the surface must require high resolution, as the slightest error can lead to inaccurate Braille and English translations.

3. FDM method

3.1. More function

The product can also display the tactile map on the screen, so that the disables can know the way more conveniently. What is tactile map: The Tactile Map is a tactile, raised map. It is designed and produced for blind people. It allows the blind to get a concrete idea of topography, transport routes and administrative divisions and to form a spatial concept. These are usually produced from thick paper, steel, cloth, wood, plastic and others. Educational maps are usually made of thick paper and plastic and are produced in schools using Braille printers or, to a lesser extent, by hand. They can be used on their own or in a booklet that is attached to a geography or history textbook or as an illustration in a textbook. Only the most important parts of the map are shown, and the legends are highlighted. Tactile maps are created by understanding the characteristics of Braille, designing a system of map legends that can be understood by the tactile senses of the blind, and then moulding and printing it. The tactile maps should not be too complex. The textured surface should be smooth to prevent fingerprints. As shown in figure 5.

Figure 5. Tactile map.

The feature of tactile map. First, the content is relatively homogeneous. Too much content, displayed in multiple layers, can reduce tactile sensitivity and affect the tactile recognition of the object by the blind. It is also small in size. The size of the tactile map should not be too large as the blind person is dependent on his fingers for the reading of the map. Secondly, the symbol system in tactile maps must be specially designed for the blind. Tactile maps have a symbol system. This system consists of simple, clear, concave and convex symbols and Braille dots. Tactile maps are generally produced using a combination of glass abrasive paper, polyester fibre and thermally expanded powder resin. Production methods include screen printing, offset printing, nylon plate printing, photosensitive resin photographic plate production and computer aided mapping methods. Tactile maps are produced in a way that is socially beneficial, but are printed in smaller quantities.

3.2. The create method of tactile map: Thermoplastic forming

(1) The preparation of the original draft: usually using illustrations from primary and secondary school geography textbooks as a starting point, which is subsequently combined to form the original tactile map. (2) Preparation of moulding materials. The materials used for the base plate include hard plastic, cardboard and wood, while the materials used for the map elements include aluminium wire, nails, pegs and wool. (Try to choose materials that are inexpensive.) (3) To make the mould, use pins, knurling knives and other tools to engrave the graphics in a majestic way. Carry out the engraving manually. (4) Add Braille notations for accurate identification of the map by the blind. (5) Moulding. The finished model of the tactile map is moulded on a thermoplastic machine, resulting in a tactile map product.

4. Conclusion

This mobile device incorporates three cutting-edge technologies: 3D printing, sensor transduction, and artificial intelligence algorithms, enabling users to communicate more conveniently. The product translates conversations or audio from others into Braille, creating a touchable output on the screen for users to read. Additionally, the device tracks the finger patterns of users with disabilities and translates them into a universal language displayed on the screen, significantly improving communication for the deaf-blind community.