1. Introduction

Recycled concrete is a material that applies recycled aggregate as one of its ingredients rather than using natural sand and stone. Recycled aggregate could be applied to replace the natural fine aggregate (sand) and natural coarse aggregate (stone), with different combinations, and the property of final concrete product could be varied. Recycled fine aggregate (RFA) has several different properties compared to natural fine aggregate (NFA). Pan et al. indicate that RFA has almost 5 times greater water absorption rate than NFA, which would cause difference in concrete particle cohesion and a wrong proportion of water in concrete manufacturing [1]. With different proportions of RFA added in concrete making, material strength for the product such as compressive strength and shear strength varied, research reveals that a proportion of RFA at around 20% could be the best solution for concrete making with balance of product strength [2]. Adding RFA also requires intermediates to fulfill the basic performance of concrete, for example, particle cohesion is reduced due to RFA property. Li pointed out that the cohesion between particles could be optimized by adding polypropylene fiber [3].

Coarse aggregate is one of the main ingredients in concrete making. In this article, the first research on the evaluation of mechanical and carbonation properties of self-compacting treated recycled coarse aggregates with two-stage mixing approaches is mentioned to indicate the property of concrete products with different amounts of recycled coarse aggregate (RCA) replacing the natural coarse aggregate (NCA). While other variables remain as constant, change proportion of SCRCA (self-compact RCA) and find out the difference in flexural strength, compressive strength, and chloride penetration depth of different products. To strengthen the idea of applying appropriate amount of RCA could be beneficial in material strength, the second research Li. et al, is introduced [4]. This experiment applied different proportions of regenerated coarse aggregate made from wasted concrete and mixed with natural coarse aggregate for coarse aggregate part. For other ingredients, apply the same amount of fine aggregate, cement, and water. Mix those ingredients to obtain different concrete, and observe material properties such as slump, apparent density, and compressive strength. Under this experiment’s value, it could be observed that 50% RCA in coarse aggregate is an ideal amount of application for the concrete produced.

By reprocessing wasted concrete as the aggregate ingredient, a solution for the waste disposal problem is provided. Applying recycled aggregate may also reduce the usage of natural aggregate materials, which brings detrimental environmental problems while mining. After investigating the current recycled aggregate applications and relative experiment testing their properties and capabilities, a better understanding about recycled aggregates in concrete performance could be perceived. Even though recycled aggregates may have defects and disadvantages for current progress, it could be predicted that more beneficial recycled aggregate application methods would be discovered since it is crucial in both economical and environmentally friendly aspects.

2. Recycled aggregate application in concrete

Recycled concrete mainly consists of recycled aggregates, cementitious materials and water in certain proportions, and sometimes certain additives are added depending on the situation. Recycled aggregates are further divided into recycled coarse aggregates and recycled fine aggregates. Li et al. made a corresponding table for the classification of recycled fine aggregates, detailing the differences between recycled and natural aggregates [5]. There are generally two sources of raw materials for recycled fine aggregates, one is discarded clay bricks and the other is discarded concrete. The apparent density and bulk density of both are smaller than those of natural sand, but the recycled fine aggregates prepared from the two raw materials also have great differences (See Table 1).

Table 1. The classification of recycled fine aggregate.

Gade | Water demand ratio | Intensity ratio | Robustness indicators | Available applications |

Ⅰ | ≤1.15 | ≥0.90 | <10% | >C30 concrete |

Ⅱ | ≤1.25 | ≥0.80 | - | <C30 concrete |

Ⅲ | ≤1.35 | ≥0.70 | - | Non-load-bearing blocks, mortar, etc |

Pan et al. found that the fines content of recycled brick fine aggregate was larger, with 49.82% of the particles below 0.63, and the water absorption rate of fine aggregate was 4.81 times higher than that of natural sand [1]. If there is a large amount of fine powder in concrete, it will lead to larger water consumption, which will virtually increase the water-cement ratio, which not only does not lead to shrinkage cracks of concrete, but also reduces the strength of concrete. The mud content of recycled brick fine aggregate also reaches 5.73%, which will not only reduce the bonding strength of the concrete aggregate interface, but also reduce its tensile strength. Therefore, it is necessary to clean the recycled brick fine aggregate before preparing recycled brick concrete. The particle size of recycled concrete fine aggregate is mostly 2.36-4.75, and its water absorption rate is 4.21 times that of natural sand. The compressive, flexural and frost resistance of the concrete prepared by the two decreased with the increase of aggregates, but the drying shrinkage rate showed an increasing trend. But among the two, recycled concrete aggregate is slightly better than the recycled brick aggregate. The surface of recycled aggregates tends to adhere to cement mortar, resulting in weak bonding, Shen found a solution by using monoacid, a natural compound that can form a layer of nanoparticles on the surface of the aggregate to increase the bonding capacity [6]. Liu found that drying recycled concrete aggregates can improve freeze-thaw properties [7].

2.1. Effect of recycled aggregate substitution rate on recycled concrete

When using recycled brick aggregates, the replacement rate reaches 50%, and the configured concrete cannot meet the concrete construction requirements, so recycled concrete is generally used. Li used five water-to-adhesive ratios and six substitution rates to analyze the compressive mild, splitting strength and flexural strength of concrete [2]. Finally, it was found that when the water-cement ratio was 0.7 and the replacement rate was not more than 20%, the compressive, tensile and flexural resistance was not lower than that of ordinary concrete. While Hao replace all natural sand with recycled aggregate, and in order to ensure the basic properties of concrete, three composite admixtures of 20% of cementitious material fly ash, slag powder and silica fume are added [8]. Li additionally found that the addition of polypropylene fiber can also improve the bonding between soil particles, and its optimal content is 0.2% [7]. Pan also studied the effects of substitution rate on compressive resistance, elastic modulus and peak change, and the substitution rates were 0%, 25%, 50%, 75% and 100% water-cement ratios of 0, 55 and 0.35, respectively, and the experiment found that with the improvement of the substitution rate, the compressive strength of concrete was lower than that of ordinary concrete, and the slump was also significantly reduced [9].

2.2. Influence of external factors on the properties of recycled concrete

Recycled fine aggregate has the disadvantages of large water absorption, Li experiments concluded that 0.04% triethanolamine and 0.5% sodium silicate can be used to improve compressive strength, among which triethanolamine effect is better [10]. Peng also got along with other methods to improve the performance of concrete recycled aggregate, under the premise of a replacement rate of 100, the recycled fine aggregate can be modified with 10% N2SO4, which can improve the compressive strength [11]. Luo chose aerated concrete for testing, when the water content of recycled concrete is large, appropriately increase a part of water reducing agent to improve this problem, and at the same time incorporate mineral admixtures, which can improve the pore structure and pore wall microstructure, and to a certain extent, the macroscopic properties of concrete can be improved [12]. To increase the strength of recycled concrete, Huo proposed that appropriate sodium silicate and silane can be added, when the content of the two is 8% and 12%, the apparent density and bulk density of concrete increase the largest, the water absorption rate and crushing index increase the most when the addition rate of the two is 10% and 12%, but when the content reaches 8% and 12%, the compressive strength and splitting tensile strength of recycled concrete reach 96.11% and 82.41% of ordinary concrete, so comprehensive consideration of this is the optimal solution [13]. Zhou found that in terms of concrete curing, steam curing has a greater impact on the resistance of concrete to chloride ion permeability, and Tian et al. also found that the appropriate addition of a little mineral admixture can improve the frost resistance and impermeability of concrete [14]. Setting the resting temperature to 20 degrees Celsius, the heating rate and cooling rate were 10 degrees Celsius per hour and 7 degrees Celsius per hour, respectively, and it was found that when the resting time was 3 hours, the heating rate was 0.2 degrees Celsius per hour, and the cooling rate was 0.15 degrees Celsius per hour, which had the best effect on the improvement of the strength of concrete in the early and later stages.

3. Results and discussion

The recycled aggregate is now applied in concrete manufacturing. Usually, aggregate would be crushed into different sizes and these pieces would be filtered and classified into coarse aggregate and fine aggregate. Coarse aggregate should be sieved through 5mm to 20mm sieve sizes. A manual wash could be given to recycle aggregate before using it to remove excessive scraps for better performance. Recycled aggregate is mostly produced from construction waste materials. With large amounts of wasted ingredients and aged materials from old structures occurring, recycled aggregate is introduced to make use of waste instead of having that construction waste end-up in landfills only. Construction waste takes the largest proportion of solid garbage produced by human, where in Europe 820 million tons of construction waste is produced annually and which is about 46% of solid waste produced. Construction waste includes all garbage produced during construction, including concrete, bricks, gravel, stone, and so on. To produce coarse aggregate, common construction waste applied is wasted concrete and bricks.

To observe the difference between recycled coarse aggregate and natural aggregate applied in concrete, relative experiments were discussed in this article. Experiment 1 discusses how different proportion of recycled coarse aggregate (RCA) behaves in concrete samples. The chemical composition of RCA in experiment 1 is shown in table 2:

Table 2. RCA chemical composition.

Compounds | Present (%) |

\( {SiO_{2}} \) | 63.56 |

\( {Al_{2}}{O_{3}} \) | 4.76 |

\( LOI \) | 9.13 |

\( CaO \) | 14.35 |

Others | 0.2 |

Based on table 1 it could be observed that RCA in this experiment is mostly composited of and, which is like concrete’s composition (is the main compound for silica fume and is the main compound for ordinary Portland cement). To observe the difference in slump flow value, compressive strength, and chloride penetration depth (other values were also determined in original article, but these three values are primarily considered). Three types of samples are applied (four in the original article, one sample contributes little about the comparison of NCA and RCA, where the first type is no RCA included, called RCA-0%, the second one contains 60% of RCA, called RCA-60%, and third one includes 100% of RCA, called RCA-100%. The sample contents are explained in table 3:

Table 3. Amount of coarse aggregate in each sample.

Sample | RCA (kg/ \( {m^{3}} \) ) | NCA (kg/ \( {m^{3}} \) ) |

RCA-0% | 0 | 830 |

RCA-60% | 462 | 332 |

RCA-100% | 770 | 0 |

The amount of cement, fine aggregate, fly ash, water, and superplasticizer in each sample are the same. Besides the types of samples, two (three in total, one approach contributes little about the comparison of NCA and RCA) approaches are applied in this experiment. The first approach is called normal mixing approach (A), in this method, mix coarse and fine aggregate for 30 seconds, then mix that with cement and fly ash for 30 seconds, and adds the rest of the material and mix them for 120 seconds. The second approach is two-stage mixing approach (B), in this method, mix fine and coarse aggregate for 60 seconds first, then mix with half amount of superplasticizer and water for 60 seconds, mix them with cement and fly ash for 30 seconds, and last mix the other half of water and plasticizer for 120 seconds. For the compressive strength test, sample dimension of 150*150*150 mm is applied. The sample is tested on a testing machine with IS:516 in accordance.

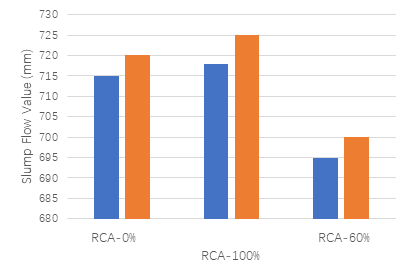

Figure 1. Slump flow value columns.

Blue columns in figure 1 represent normal mixing approach (approach A), and orange columns represent two-stage mixing approach (approach B). In figure 1, approach A has a lower slump flow value than approach B in three samples concretes. RCA-60% has the highest slump flow value and RCA-100% has the lowest slump flow value, this result implies that mixing RCA with NCA in concrete may potentially be getting a failure in slump-flow test comparing to the result of using RCA as the only aggregate ingredient, the difference between the maximum and minimum slump flow value is 30mm, which would not make a great difference but still noticeable. Using a normal mixing approach could reach a lower slump flow value for the same sample compared to application of approach B.

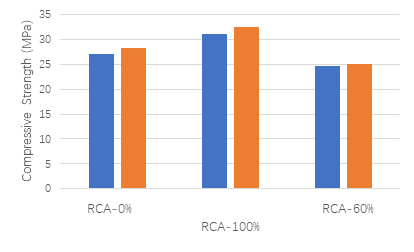

Figure 2. Compressive strength columns.

RCA-60% has the highest compressive strength and RCA-100% has the lowest compressive strength among the three samples. This figure indicates that the mixture of RCA and NCA could increase the compressive strength for sample concrete comparing to pure RCA or NCA sample, while the ratio of mixture is not determined so far.

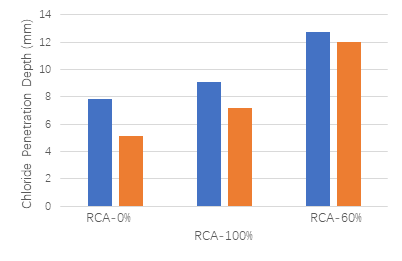

Figure 3. Chloride penetration depth columns.

According to Figure 3, as RCA increases in concrete samples, the chloride penetration depth increases, this phenomenon indicates that adding RCA would cause a negative effect on chloride penetration prevention. Chloride would seep into the concrete structure and reduce the material’s strength, and decrease concrete’s service life. From these three sub-experiments’ outcome, a simple pattern could be observed that add RCA in concrete would present a better slump flow value, excessive amount of RCA added would cause some defaults such as lower in compressive strength and higher chloride penetration depth. Therefore, RCA could not be added into concrete blindly; with an appropriate amount of RCA added to concrete, the strength of concrete would be stronger.

4. Conclusion

With the global low-carbonization, recycled concrete such as green building materials has become a key research object. This paper through the analysis of many research papers and experiments on this aspect found that compared with ordinary concrete, the composition of coarse and fine aggregates and natural aggregates performance of a little different, due to the waste into recycled aggregate technical problems and other external factors, recycled aggregate has too large porosity, low strength, weak adhesion and other problems. In this paper, the design method of the mix ratio of recycled aggregate concrete is studied and the current standard and the design method of recycled concrete are compared and tested, and the more suitable mix ratio design method of recycled concrete is obtained, and the effect of monoacid and polypropylene fiber on improving the adhesion of aggregate is studied, and different samples are analyzed to compare the differences in RCA. A variety of admixtures, such as sodium silicate, methane and so on, were collected to increase the strength and apparent density of concrete. The research in this paper summarizes the research angles, research strategies, research methods and means of many researchers, and conducts a systematic and comprehensive analysis of recycled concrete, which provides ideas and references for future researchers. However, there is not much research on recycled concrete, and the technology for processing and preparing recycled aggregates is not mature enough, and there are no clear classification rules for recycled waste. At the same time, the technology of preparing recycled concrete is not skilled enough, and the performance in terms of strength and durability cannot completely replace ordinary concrete. Coupled with the fact that the cost of preparing recycled concrete is about 15% higher than that of ordinary concrete, there is not much advantage in regenerating concrete in terms of production costs. However, regenerated concrete also has good development prospects. Nowadays, recycled concrete also has good development prospects, with the popularization of the concept of sustainability, people began to pursue a green and low-carbon lifestyle, turning their attention to recycled concrete. At the same time, in the waste concrete treatment, recycled concrete completely saves treatment costs and transportation costs, and alleviates the lack of natural aggregates to a certain extent. Coupled with the fact that government departments began to pay more and more attention to this aspect of research, and began to invest a lot of research and development funds and equipment, the promotion and utilization of recycled concrete has great prospects.