1. Introduction

With the achievement of the “First Centenary Goal”, another 15 years of effort will be made based on this goal, aiming to achieve socialist modernization by 2035. The vigorous development of the internet and electronic commerce has led to rapid growth in the electronic logistics industry. In order to make transportation and loading and unloading more efficient and faster, an increasing number of automated devices are being applied in the field of logistics.

According to a notice issued by Yunnan Province, there is a focus on the construction project needs of transportation hubs, logistics hubs, and other key nodes in Yunnan and surrounding areas. This is to promote the development of intelligent logistics system equipment suitable for stations, docks, airports, and large-scale logistics hubs, aiming to achieve high-quality development in the manufacturing industry. To meet the needs of industries such as tobacco, food, and express logistics, there is a strong need to accelerate the research and application of specialized intelligent logistics system equipment such as high-speed stackers, rail-guided vehicles (RGV), automatic guided vehicles (AGV), rapid sorting machines, and intelligent high-density storage shuttle plates. This indicates that intelligent logistics carts have become the mainstream direction for future equipment development.

Traditional logistics operation models have many disadvantages, such as long manual handling times, low efficiency, easily occurring errors in manual sorting, and inability to meet the needs of small batch and multi-category requirements. Additionally, labor costs continue to increase, while emerging labor forces lack interest in such work [1]. To improve this situation, intelligent logistics technology has emerged, which can upgrade logistics modes by introducing automated equipment and information technology. Automated equipment can improve logistics operation efficiency and reduce error rates, such as high-speed stackers and rapid sorting machines.

An intelligent logistics cart is a type of robot based on intelligent perception technology and autonomous navigation technology, used in logistics handling and automatic assembly fields. Compared to traditional automatic guided vehicles, intelligent logistics carts are more suitable for modern logistics warehouse environments because they are more flexible and compact, allowing them to easily navigate through narrow aisles. Traditional handling robots require navigation through ground-installed guide bands, which is less suitable for dynamic storage environments and processes. In contrast, intelligent logistics carts can perceive the environment and plan paths using advanced sensors like laser radar, thus avoiding this inconvenience [1].

In summary, the widespread application of intelligent logistics carts helps optimize the efficiency of logistics sorting and handling, reduce related costs, and enhance the sustainability of logistics management. Furthermore, the application fields of intelligent logistics vehicle-related technologies are extensive, including material handling, hotel transportation, military, and hazardous environments. Therefore, designing and implementing logistics vehicles with higher reliability and accuracy is an important research direction in the logistics industry. It is important to consider various indicators such as product performance, safety, and usability comprehensively [1].

2. System Overall Design

2.1. System Experimental Platform

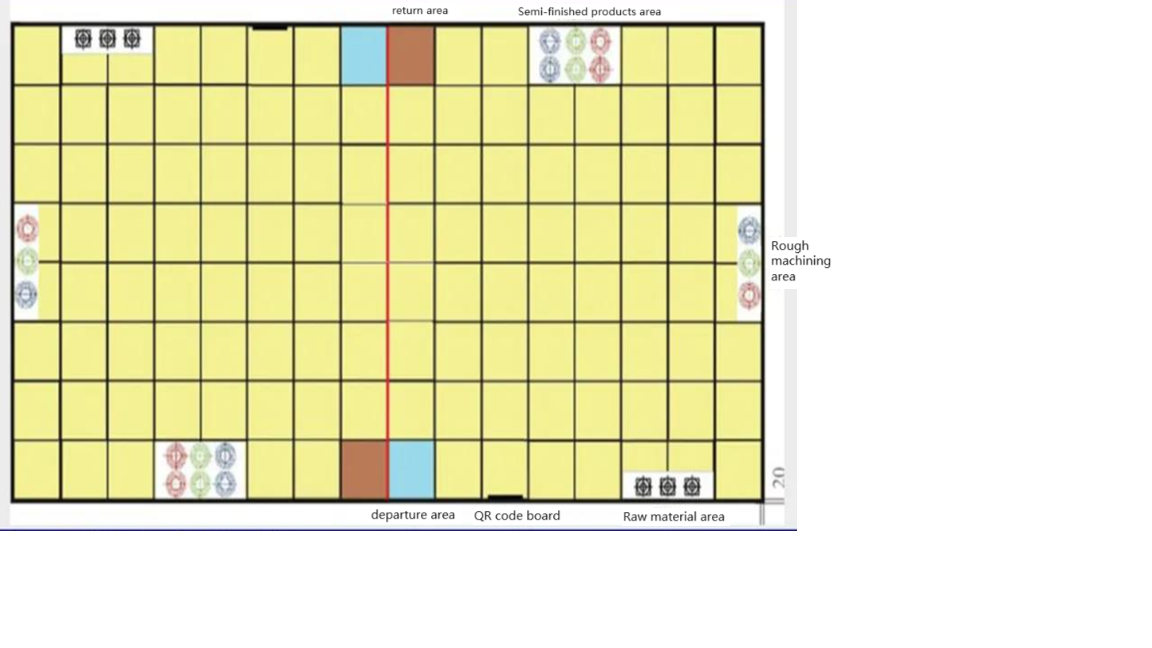

This paper takes the National University Student Engineering Training Comprehensive Ability Competition’s intelligent logistics cart as the experimental background, as shown in Figure 1. An experimental platform with Arduino as the main control board is adopted. This platform integrates a self-propelled car with a robotic arm, providing theoretical data for product design.

The workflow of the entire system is as follows: place the intelligent logistics cart in the departure area (blue square position in the figure). After the intelligent logistics cart is started, it travels along the black path. After recognizing the QR code, it obtains the task code. In the raw material area, the open MV module identifies colors, and the robotic arm grabs the corresponding blocks, placing them in the rough processing area. This process is repeated six times. Then, from the rough processing area, based on the color ring in the semi-finished product area, the corresponding color blocks are placed. Once completed, the cart returns to the endpoint (brown square position in the figure).

Figure 1. Experimental Platform for Intelligent Logistics Cart

2.2. Overall System Design

To achieve intelligent handling processes for the intelligent logistics cart, the system should include the following aspects:

(1) Vehicle Structure:

The design of the vehicle structure for the intelligent logistics cart should take into account sensor installation and equipment connections. The structure should be sturdy, expandable, easy to install, and maintain. It should allow sensors, microcontrollers, batteries, and other equipment to be conveniently installed inside the vehicle body. The design of the vehicle body should adhere to the principles of low center of gravity and high strength. Lightweight and high-strength materials such as aluminum alloy should be used for manufacturing the vehicle body. Additionally, large-diameter wheels should be used to reduce friction, thereby lowering the center of gravity of the vehicle body and enhancing the stability of the entire system. A color recognition camera can be installed on the top of the vehicle body, while motor drives and automatic tracking systems can be installed on the bottom to ensure stable movement of the cart.

(2) Power Supply System:

The power supply system of the intelligent logistics cart provides power to its electronic devices. Batteries are used as the main power source, with external charging devices for recharging. When designing, attention should be paid to ensuring power supply stability and avoiding factors such as voltage fluctuations and current interference that may affect system operation. Additionally, the charging system should be designed to be safe, fast, and efficient, considering the adoption of intelligent charging technology for charging control and status monitoring. While considering cost control, appropriate battery and charger components should be selected to minimize the overall system design cost. Overall, the power supply system of the intelligent logistics cart needs to be reasonably designed and optimized according to practical application requirements to ensure stable operation and reliability of the system.

(3) Locomotion Mechanism:

The locomotion mechanism of the intelligent logistics cart mainly consists of wheels and motors. To ensure that the cart can move, turn, and stop normally, the maneuverability and load capacity should be fully considered when selecting the number of wheels. It is important to choose suitable motors and configure drive modules reasonably based on the load conditions and expected routes of the cart to ensure efficient and stable movement. Additionally, considerations should be made for the energy consumption and endurance of the entire system.

(4) Handling System:

The robotic arm of the intelligent logistics cart is primarily responsible for handling tasks, requiring high maneuverability, good stability, intelligent control, and reliable quality. In the design of the robotic arm, the most suitable type should be chosen based on different handling tasks. Through rational driving methods and transmission devices, the robotic arm should possess good maneuverability and stability. Control modules and sensors should be integrated to achieve intelligent control of the robotic arm. Regarding the quality and reliability of the robotic arm, attention should be paid to material quality, structural design, and safety protection to ensure both quality and reliability while improving the efficiency and accuracy of the robotic arm’s work.

2.3. Overall System Framework Design

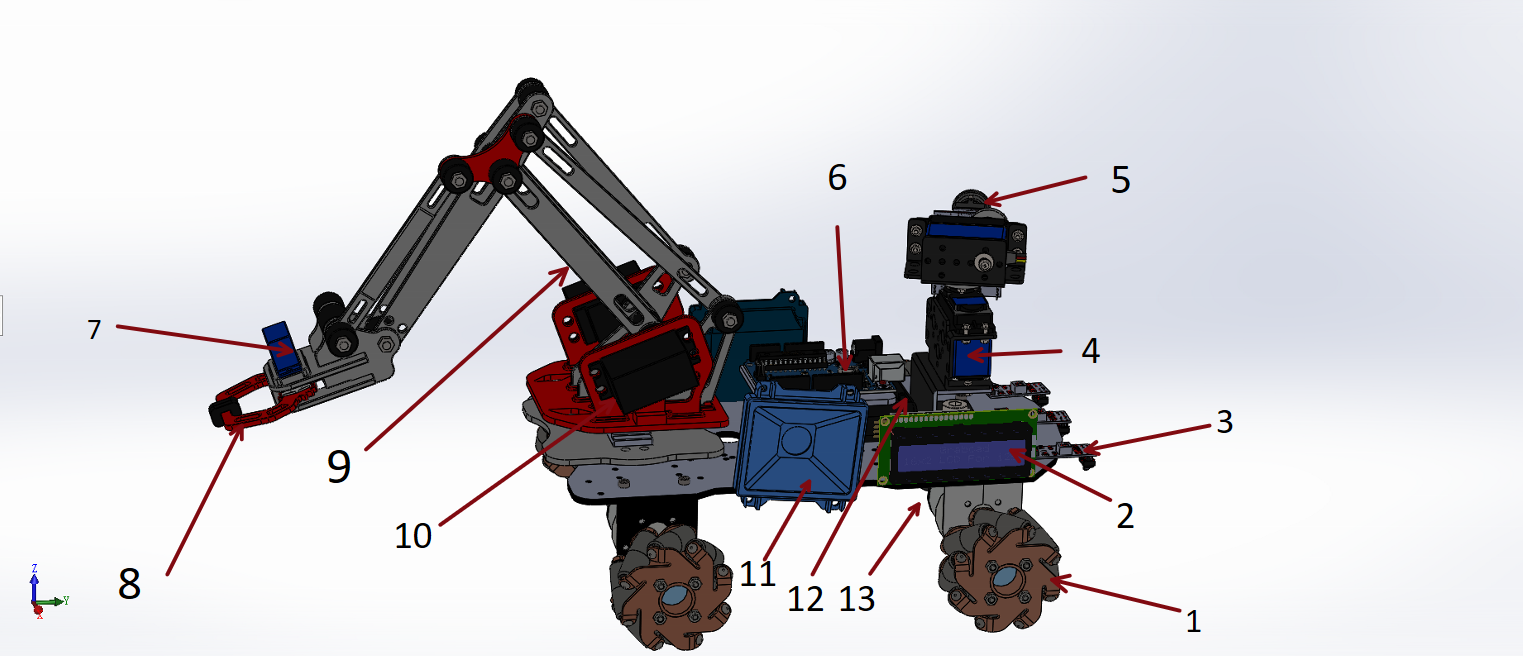

Figure 2. Three-dimensional Model of the Intelligent Logistics Cart

1-Mecanum Wheels

2-LCD Display Screen

3-Infrared Sensor

4-Color Recognition Module Servo Motor

5-Color Recognition Module (openMV)

6-Arduino Main Control Board

7-Gripper Servo Motor

8-Gripper

9-Mechanical Arm

10-Mechanical Servo Motor

11-QR Code Scanning Module

12-12V Battery

13-DC Reduction Motor

The intelligent logistics cart mainly consists of a drive device, tracking device, and handling device.

(1) Drive Device:

The drive device ensures the normal rotation of the cart wheels, thereby reliably propelling the cart’s movement.

(2) Tracking Device:

The tracking system enables the cart to travel within the warehouse along a predetermined route, thereby avoiding possible collisions and accidents. Additionally, the tracking system helps staff quickly locate the position and path of the cart.

(3) Handling Device:

The handling device is the basic equipment for the cart to complete handling tasks. To ensure the efficiency and stability of the cart’s handling work, suitable handling devices should be selected according to actual needs, and relevant control modules and sensors should be configured reasonably. It is important to adhere to relevant safety standards and effectively maintain and upkeep the handling device.

3. Structural Design

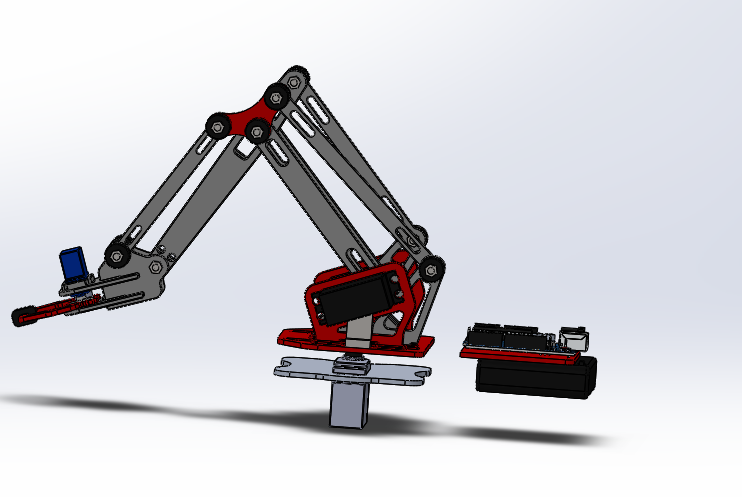

3.1. Mechanical Arm

The mechanical arm is a robotic device capable of achieving high flexibility through multiple joints and actuators. Its principle is based on multiple motors, transmission mechanisms, sensors, and supporting control systems. By employing computer algorithms to complete forward and inverse kinematics, trajectory planning, and feedback control, the mechanical arm achieves control over its own position, speed, and force, thus facilitating superior performance in industrial manufacturing, medical care, scientific research, or rescue applications.

The mechanical arm of the intelligent logistics cart is manufactured using 3D printing technology and is equipped with four servos, enabling its movement through coordinated control. The base servo of the mechanical arm can rotate 360 degrees and has four degrees of freedom, including XYZ directions and rotational direction, enabling point-to-point handling and planar movement. Its structural diagram is shown in Figure 3, where the robot’s degrees of freedom refer to the number of independently controlled joints, which is an important parameter in robotics. The higher the degrees of freedom, the more flexible the robot, but the design complexity, overall requirements, and costs also increase accordingly. Therefore, in the design process of this product, I chose a four-degree-of-freedom mechanical arm, which offers higher stability and lower cost, suitable for simple tasks such as item handling, assembly, and disassembly.

The realization of arm movement adopts a link mechanism, specifically employing a planar four-bar linkage mechanism. A planar four-bar linkage mechanism consists of four linkage rods forming a rectangular configuration. Two opposite linkage rods serve as the base linkage, while the other two linkage rods serve as the active linkage, and their connection method is known as a double rocker mechanism. The principle of the planar four-bar linkage mechanism is based on the double rocker mechanism, utilizing mechanical kinematics and mechanism analysis to achieve complex trajectory and motion planning. By adjusting the proportions and dimensions of each linkage, different four-bar linkage mechanisms are constructed, realizing various attributes.

The advantages of the planar four-bar linkage mechanism are evident: firstly, it saves space, enabling complex movements even within small-sized spaces; secondly, it offers excellent performance, achieving precise, smooth, and rapid trajectory movements; thirdly, it has a simple structure, easy installation, and maintenance. Therefore, in robotics control and automation applications in industries such as industrial manufacturing, medical care, the application of planar four-bar linkage mechanisms is extremely extensive. Thus, the planar four-bar linkage mechanism is more suitable for the motion requirements of this product compared to other mechanisms.

Figure 3. Three-dimensional Diagram of the Mechanical Arm

3.2. Wheels

This product design offers options of regular wheels, omni-directional wheels, and Mecanum wheels. Regular wheels rely on differential steering to achieve turning. Differential steering transfers power from the drive shaft to the two drive wheels through a differential, giving the wheels different speeds to achieve more flexible turning [2]. However, this turning method is not suitable for operations requiring immediate turning within a small range, so regular wheels are not used in this product.

Mecanum wheels are a special wheel design that enables omnidirectional movement. By setting peripheral axles on the central wheel, part of the turning force of the wheels is converted into normal force of the wheels, adjusting the direction and speed of the wheels in each direction to generate any directional resultant force vector, thereby achieving free movement without changing the direction of the wheels. Additionally, Mecanum wheels have multiple small rollers, providing advantages such as flexibility and reliability [3].

Mecanum wheels are becoming increasingly popular in robotics competitions due to their ease and efficiency of installation. They can be installed on parallel axles just like traditional wheels. Achieving similar functionality using omni-directional wheels requires setting specific angles, such as 60°, 90°, or 120°, on multiple hub axes, which presents challenges in precise manufacturing. Therefore, choosing Mecanum wheels has become a priority option in the field of robotics manufacturing and design.

3.3. Chassis Design

When designing the chassis of the intelligent cart, it is necessary to consider the functions and performance characteristics required by the cart. For the selection of chassis materials, aluminum alloy plate is a relatively excellent choice. This is because aluminum alloy plate possesses several characteristics:

Firstly, the density of aluminum alloy plate is smaller than other commonly used metal materials such as iron or copper, approximately 2.7g/cm³, which is only about 1/3 of theirs. This allows the use of aluminum alloy material in constructing the chassis to reduce the weight of the cart, thereby enhancing the load-bearing capacity and stability of the cart.

Secondly, aluminum alloy plate is one of the commonly used materials for manufacturing cart chassis, with excellent strength and corrosion resistance. Additionally, aluminum alloy plate is easy to process and can be made into cast aluminum alloys suitable for casting processes or aluminum alloy plates suitable for deformation processing by adding alloying elements. This good plasticity is crucial for chassis design, allowing for various shapes and combinations to be flexibly achieved while ensuring load-bearing capacity and stability. Therefore, the use of aluminum alloy plate not only increases the design flexibility and operability of the cart chassis but also improves its overall performance and lifespan.

Thirdly, aluminum alloy plate has high strength, and further strengthening can be achieved through cold working processes, making it more durable. This significantly enhances the performance of the cart, achieving more efficient logistics transportation.

Fourthly, aluminum alloy plate has excellent corrosion resistance. Its surface naturally forms a dense aluminum oxide protective film, effectively protecting the aluminum matrix from further corrosion. This characteristic enables the aluminum alloy chassis to have a longer service life, improving the stability and reliability of the cart.

Lastly, aluminum alloy plate has excellent electrical and thermal conductivity, second only to good conductors such as silver, copper, and gold. This plays a positive role in the heat dissipation and circuit connection of electronic components such as communication, sensing, and control in intelligent logistics carts.

Therefore, considering the above factors comprehensively, selecting aluminum alloy plate as the chassis material for intelligent logistics carts is a very suitable choice.

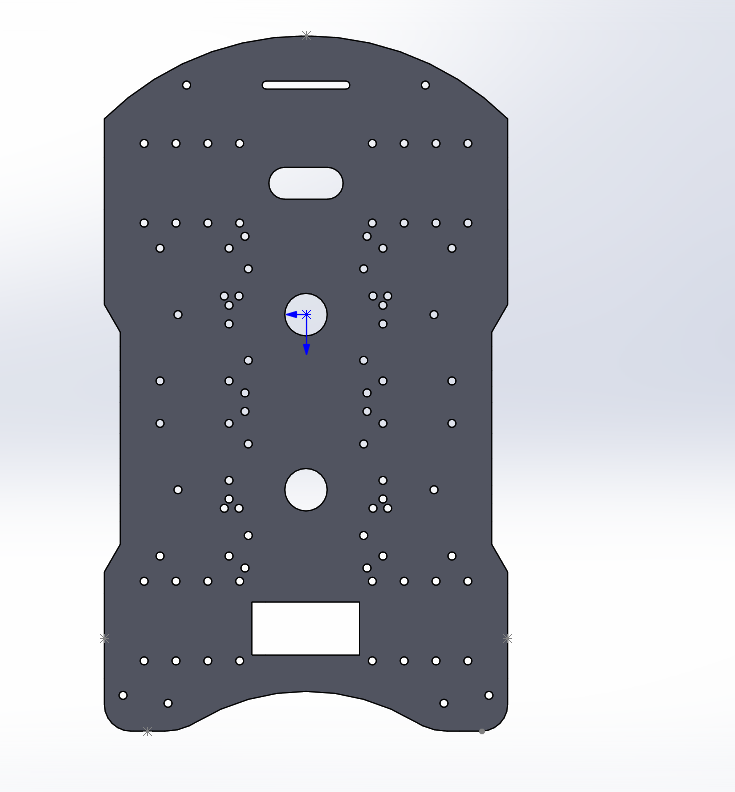

Regarding the structure, a three-dimensional chassis model measuring 152mm in length, 262mm in height, and 3mm in width was designed using SolidWorks. This structural design meets the requirements for strength and rigidity, and the necessary holes can be designed according to the dimensions of the selected hardware [4]. For example, rectangular holes of 40*20 and circular holes of 3mm were designed to facilitate the placement of servos at the bottom of the mechanical arm and the fixation of infrared sensors. To ensure the practical development of this product design, I chose a design with multiple holes in the chassis. The purpose is that in the process from theoretical design to actual product realization, if the dimensions of hardware available in the market do not match the hole dimensions of the chassis, nylon cable ties can be used for fixing. This approach greatly increases work efficiency, saves time, and reduces costs. The structural diagram is shown in Figure 4:

Figure 4. Chassis Design Diagram

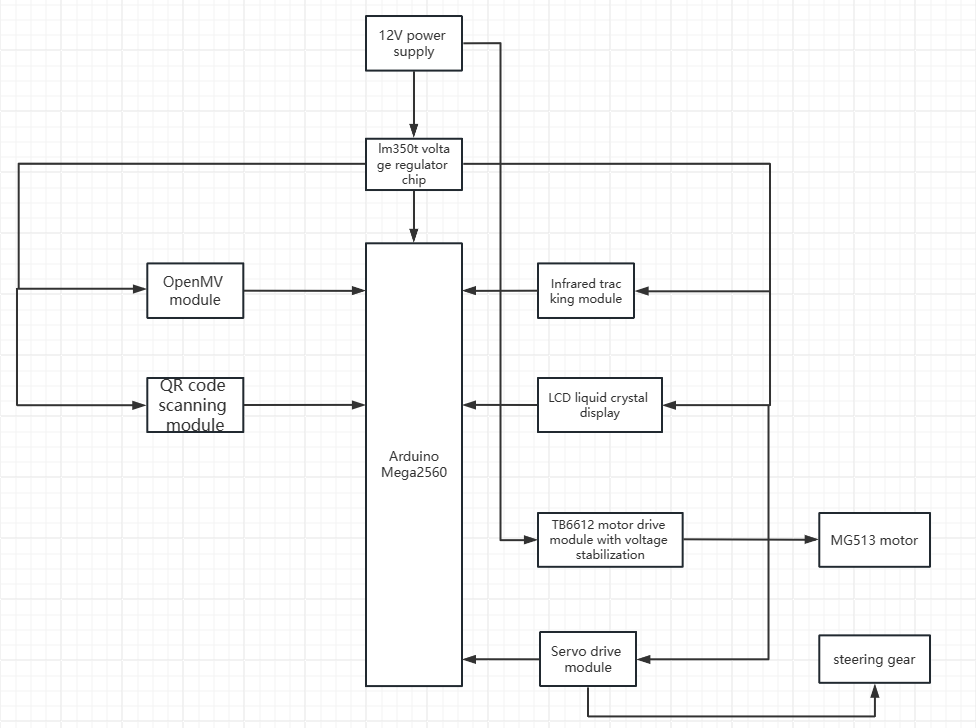

4. Hardware Selection

The overall control schematic diagram of the designed product is shown in Figure 5. The main hardware required for the overall circuit includes Arduino Mega2560, MG513 motor, TB6612 motor driver module with voltage stabilization board, infrared tracking module, Open MV module, QR code scanning module, and servo drive module [5].

Figure 5. Control Schematic

4.1. Color Recognition Module

The designed product adopts the Open MV Cam H7 camera module as the core component. Compared with the TCS3200 color recognition sensor, the Open MV Cam H7 camera module has higher color resolution and a wider color range. It can also perform real-time image processing and machine vision applications. Additionally, the Open MV Cam H7 camera module has stronger processing capabilities, enabling easy operation of deep learning algorithms and neural networks, thereby achieving more complex image processing tasks. Furthermore, the Open MV Cam H7 supports the Python programming language, facilitating more convenient development and customization [5].

4.2. Servo Drive Module

The intelligent logistics vehicle needs to control the movement of the robotic arm to complete complex tasks, using the high-power servo motor MG995. Initial experimental results showed that the required microcontroller could not drive this servo motor. To address this issue, the design solution considers using the PCA9685 16-channel servo drive board. This drive board can efficiently control multiple servo motors, achieve higher precision control, omit MCU I/O pins, alleviate the burden on the MCU, and provide better scalability. By using the PCA9685 drive board, the robotic arm can be controlled more effectively, enhancing the performance of the intelligent logistics vehicle.

4.3. Motor Module

For driving the intelligent logistics vehicle, the product adopts the MG513 DC geared motor with a Hall encoder disc. After consulting relevant materials and considering the design scheme of this product, the TB6612 with a voltage stabilization version (D153B) is utilized. This module can simultaneously drive 2 motors in both forward and reverse directions with stepless speed regulation. Its PWM dead zone is much smaller than that of the L298N, and it does not require a logic power supply reference voltage as it uses the built-in stabilized output of 5V. It also has built-in short circuit protection and over-temperature protection mode.

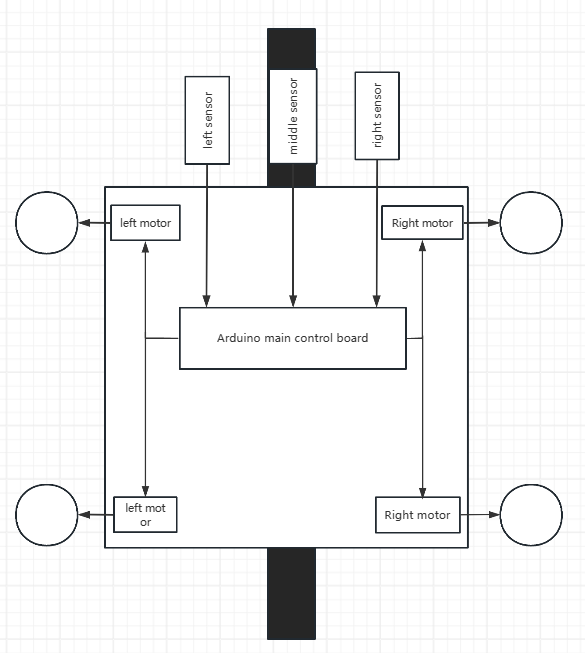

5. Implementation of Automatic Tracking Function

The automatic tracking module is a critical control part of the intelligent vehicle, consisting of three infrared tracking sensors. By detecting the color of the ground, the module controls the vehicle to travel along the black track. The basic principle of this module is as follows: the sensors continuously emit infrared signals, which are reflected back after hitting the ground. Once the feedback signal of the sensor changes, the Arduino adjusts the motor speed to guide the vehicle back to the correct track. In specific implementation, when the vehicle deviates from the track, Arduino detects the signal change through sensors to determine the vehicle’s position. If the left or right sensor detects a yellow signal, it indicates that the vehicle has deviated from the track. At this point, Arduino judges whether the vehicle has completely left the track based on the black signal detected by the middle and opposite sensors. If the vehicle has left the track, Arduino adjusts the motor speed to make the vehicle turn to the opposite side and return to the track [2]. The effect of the tracking function of the intelligent logistics vehicle is shown in Figure 6.

Figure 6. Tracing Effect Diagram of Intelligent Logistics Vehicle

6. Conclusion

With the rapid development of e-commerce and the logistics industry, the number of express orders continues to increase. However, in the process of manual sorting, problems such as low efficiency and heavy workload for workers have emerged. This not only affects the work efficiency of express delivery companies but also increases labor costs. Therefore, to solve this problem, intelligent logistics vehicles have emerged.

This intelligent logistics vehicle, through functions such as automatic tracking, color recognition of items, scanning QR codes to obtain handling tasks, and omnidirectional grasping of items, can efficiently and accurately perform tasks such as logistics sorting and handling. The control platform used by the vehicle is Arduino, and the hardware devices used include infrared tracking sensors, mechanical arms, color recognition sensors, Open MV color recognition sensors, QR code modules, and so on. These hardware components are relatively inexpensive yet practical in function.

The emergence of intelligent logistics vehicles has greatly improved the work efficiency of logistics companies, reduced labor costs, and is also an important milestone in the intelligence of the industry. To further enhance the development level of intelligent logistics vehicles in China, we need to vigorously develop related technologies for intelligent logistics vehicles. Doing so will not only improve the work efficiency of enterprises and reduce labor costs but also promote the intelligence and automation of the entire logistics industry. At the same time, research on intelligent logistics vehicle technology still has a long way to go, requiring continuous investment of more effort, time, and funds.

In the future, intelligent logistics vehicle technology will also develop towards higher goals, including high speed, intelligence, high precision, and good linearity. In terms of high speed, intelligent logistics vehicles need to be able to move quickly to improve the efficiency of sorting, handling, and transportation. In terms of intelligence, intelligent logistics vehicles need to be able to learn and make decisions autonomously. In terms of high precision, intelligent logistics vehicles need to be able to accurately identify items to avoid mis-sorting and mis-transportation. In terms of good linearity, intelligent logistics vehicles need to be able to flexibly travel and handle items under different ground conditions.

The comprehensive application of technology to achieve intelligent logistics vehicles is one of the hotspots in the current development of intelligent and automated logistics industry. Continuous technological innovation and intelligent upgrades can optimize logistics industry services, improve efficiency and quality, and promote its sustainable and healthy development. With the continuous development of the logistics industry and the improvement of intelligence levels, the application of intelligent logistics vehicles will not only enhance the efficiency of traditional logistics but also contribute more to the development of the social economy with its advantages of high efficiency, intelligence, and sustainability.