1. Introduction

The architectural and construction realm has continually evolved, seeking innovative methods and materials to enhance structural integrity, durability, and sustainability. Among the myriad of challenges faced by civil engineers and architects, the axial compression capacity of reinforced concrete stands paramount. This property, pivotal to the load-bearing ability of structural elements, directly impacts the safety, longevity, and economic efficiency of built structures.

Traditionally, the axial compression capacity of concrete has been enhanced through various means, ranging from altering mix proportions to introducing steel reinforcements. However, the quest for superior materials and techniques remains incessant, driven by the increasing demands of modern infrastructure and the evolving challenges posed by environmental and socio-economic factors.

In recent years, a spectrum of materials—from naturally occurring fibers to industrially processed ashes—has entered the spotlight, showing promise in augmenting the axial compression capacity of concrete. These materials, sourced from diverse origins, not only offer structural advantages but also present solutions addressing sustainability and waste management concerns.

This paper delves into the potential of several such materials, including basalt fiber, succinic acid, rice husk ash (RHA), Robo sand, glass sand, cattle manure ash (CMA), and metakaolin. Through a comprehensive analysis of their properties, production methods, and application in concrete matrices, this paper aims to provide insights into their viability and effectiveness in enhancing the axial compression capacity of reinforced concrete. By doing so, this paper hopes to contribute to the growing body of knowledge that guides the future of sustainable and high-performance construction.

2. Materials analysis

2.1. Basalt fiber

Basalt fiber, a natural material derived from volcanic rock, is gaining increasing attention in the realm of civil engineering, particularly for the enhancement of axial compression capacity in reinforced concrete structures. The integration of basalt fiber into concrete matrices has showcased significant advantages over traditional materials.

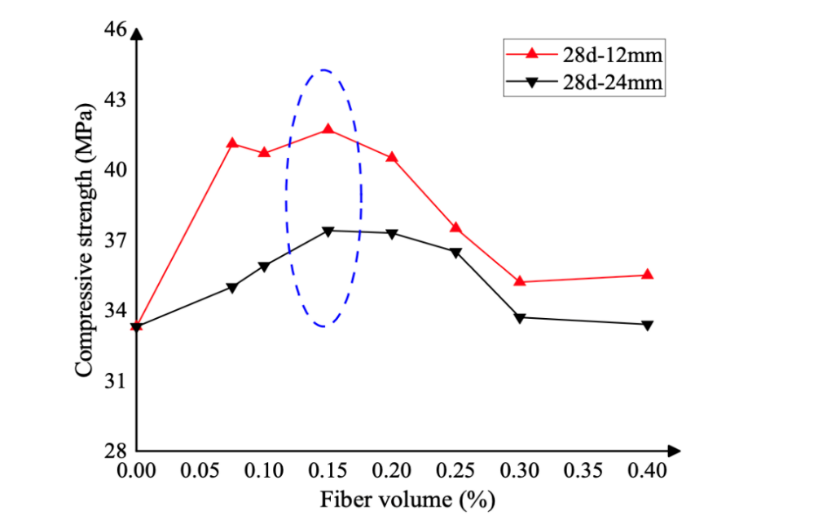

In a study conducted by Wang et al. [1], the ultimate bearing capacity of reinforced concrete with different volumes and lengths of basalt fiber is tested. As shown in figure 1, the result shows that as the fiber volume and fiber length increase, the compressive strength of basalt fiber reinforced concrete firstly increase when the fiber volume is below approximately 0.15%, and fiber length is below 12mm. However, when the fiber volume is higher than 15%, the compressive strength begins to be negatively related to the fiber length and fiber volume. In addition, under the optimum fiber length and volume, which are 12-24 mm and 0.15% respectively, the bearing capacity can increase by 28%. In addition to the compressive strength, the concrete reinforced by basalt fiber also has higher slope of N-ε curve, the concrete with basalt fiber is relatively inelastic.

Figure 1. The compressive strength of the basalt-fiber-reinforced concrete with different fiber lengths and volume contents [1].

In another experiment executed by Shilov et al. [2], the differences between basalt fiber reinforced concrete and common concrete under compression are also analyzed. The results of testing ten simples revealed that 10% increase in coarse basalt fiber content increased the maximum compressibility of different kinds of concrete by around 20%. In terms of failure of specimens, horizontal cracks can be observed on conventional concrete without basalt fiber immediately before the failure while this feature appears on basalt fiber reinforced concrete under a higher compressive force. The ultimate compressive strains for fiber-reinforced concrete short columns doubled for both lightweight and heavy aggregate. The increase in the ultimate compressive strength of the concrete allows for the use of steel reinforcement with higher strength in compressed elements. This enables the structures to have higher load-bearing capacity or reduced material consumption.

Overall, adding basalt fiber into concrete, especially 12-24 mm basalt fiber, can significantly enhance the compressive capacity and ultimate compressive strain of concrete, which enables production of high-performance concrete with less materials, providing novel option for contemporary buildings. In practical applications, incorporating basalt fiber into concrete has become a standard practice for many modern architectural and infrastructural projects. This adoption is not solely based on its enhanced compressive strength, but also because it offers architects and engineers greater design flexibility. For instance, buildings in seismically active regions can better withstand damages from earthquakes due to the improved compressive and tensile properties of basalt fiber concrete. However, while basalt fiber concrete demonstrates superior performance in laboratory settings, real-world applications still require considerations like cost, supply chain stability, and compatibility with other construction materials. Therefore, it’s advisable to conduct thorough research and planning before implementation to ensure optimal performance and cost-effectiveness.

2.2. Succinic acid

Succinic Acid is an organic acid ubiquitously found in nature. It occurs either in its pure form or in esterified versions. Produced by converting maleic anhydride through catalytic hydrogenation, succinic acid serves as a prominent additive in construction materials.

Parashar et al. [3] carried out a study analyzing the differences on compressive strength of concrete caused by succinic acid. Theatrically, the succinic acid in concrete can react with calcium oxide, which can eliminate the excessive lime and generate calcium succinate, so the concrete with succinic acid can obtain higher performance. In this experiment, different proportion of succinic acid from 0% to 2% was added to the M20, M25 and M30 concrete respectively, and their compressive strength was tested on 7th and 28th day. The results showed that succinic acid, as a kind of plasticizer, can slightly increase the performance of concrete. In terms of 7th day Compression strength, succinic acid’s effect is the most significant for M25 concrete, which was approximately 11% higher by adding 1% of succinic acid. In terms of 28th day Compression strength, it has relatively stronger effect on M20 concrete, and it provided about 6% increase in compressive strength by adding 1% of succinic acid.

In summary, succinic acid, as a construction material additive, showcases immense potential in augmenting the compressive strength of concrete, offering new research avenues and application opportunities in the realm of modern construction material science.

2.3. RHA & Robo sand

In recent years, the potential of RHA and Robo sand as partial substitutes in concrete has garnered significant attention. These alternative materials offer not only an environmentally friendly solution but also present an innovative approach to enhancing the strength properties of concrete.

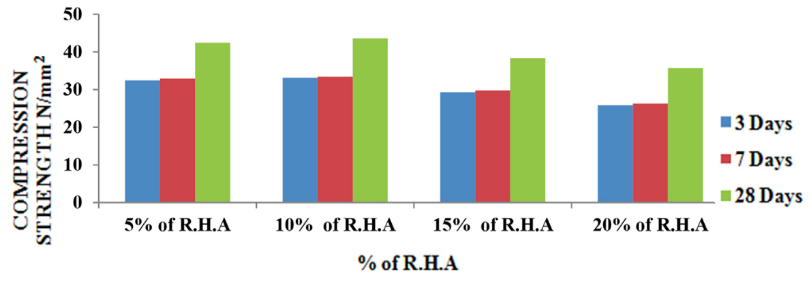

Chetan and Aravindan’s experimental study delved into the impact of substituting natural sand and cement with RHA and Robo sand on the strength characteristics of concrete. As shown in figure 2, The findings indicated that when RHA was incorporated at a proportion replacing 10% of the cement, the compressive strength of the concrete peaked. This suggests that RHA can serve as an effective cement substitute, bolstering the structural strength of the concrete. In addition, the data also showed that the compressive strength of concrete with RHA during first 7 days did not increase noticeably, but during after days, its strength increase abnormally while the conventional concrete’s strength growth is more stable. On the other hand, when Robo sand was used to replace 50% of the natural sand, the compressive strength of the concrete also reached its maximum. This implies that Robo sand emerges as a promising alternative to natural sand, contributing to enhanced strength and durability [4].

Figure 2. The compression strength (N/mm2) values for various proportions of RHA [4].

Furthermore, according to Su and Xu [5], when concrete contains 55.2kg rice husk as per m^3, its compressive strength in long term can be enhanced significantly. Although its compressive strength is lower than the one without RHA within 7 days, the compressive strength increased dramatically during the after 83 days and exceeded the concrete without RHA. However, when the content of RHA further increased, its performance during the whole test period dropped to a lower level compared to concrete without RHA.

In conclusion, RHA and Robo sand, as partial replacements in concrete, provide a beneficial strategy for optimizing the structural performance of concrete. These insights offer invaluable references for engineering applications and lay a robust foundation for further research and practical implementation. However, it is also noticeable that excessively adding RHA and Robo sand can results in serious decline in compressive capacity.

2.4. Glass sand

Glass sand has emerged as a novel material of interest in concrete research in recent years. Due to its distinct physical and chemical properties, glass sand is seen as a promising substitute to natural sand, especially in enhancing the axial compression capacity of concrete. Compared to natural sand, glass sand possesses higher hardness and abrasion resistance, allowing for superior bonding in concrete mixtures. Moreover, the chemical stability of glass sand ensures long-term performance of the concrete.

Based on Su and Xu’s study, the triaxial compression peak stress was linearly correlated with confining pressure, and they found that adding glass sand to concrete can improve its confining pressure under high triaxial compression stress. However, it is also noticeable that under the lower triaxial pressure, the axial compression capacity of concrete with glass sand was lower than the one without glass sand. In this study, author also indicated that this might because glass sand has sharper appearance which can attribute to the tight bonding inside of the concrete [5].

Moreover, in another study conducted by Su and Xu [6], authors revealed that without triaxial compression, adding glass sand can decrease concrete’s axial compression capacity. However, despite the decrease in compression capacity, the concrete with glass sand received less damage under the same strain compared to conventional concrete.

In conclusion, glass sand, can improve the compression capacity of concrete in certain circumstances, and inappropriate application of glass sand can lead to decrease in compression capacity. Although the usage of glass sand is limited, from environmental perspective, as a recycling material, can save river sand resources and reduce alkali–silica reaction.

2.5. CMA

CMA has recently gained attention as an environmentally friendly and sustainable supplementary material in the field of concrete production. The use of CMA not only provides an avenue for waste management but also offers potential benefits in enhancing the mechanical properties of concrete.

Zhou et al. [7] highlighted the critical role of particle size in determining the compressive strength of CMA-infused concrete. According to the result, the compressive strength of concrete is positively correlated to the particle size of CMA when the size is below 3 μm or above 65 μm, and its effect is significant especially when the particle size is below 3 μm. This is attributed to the increased surface area provided by smaller particles, which leads to better bonding and distribution within the concrete matrix.

However, from another experiment conducted by Zhou et al. [8], there is a conflicting result that CMA-infused concrete’s compressive is the greatest when the infused size is between 40-60, which might be caused by the difference in production of CMA and other components in concrete. Generally, the utilization of CMA in concrete production presents both environmental and economic benefits. Environmentally, it aids in waste management by reducing the amount of cattle manure that would otherwise be discarded. Economically, CMA serves as a cost-effective alternative to traditional concrete additives, reducing the overall cost of concrete production. However, there are still challenges associated with its use. The variability in CMA composition, depending on the source and burning process, can influence the consistency of its performance. It is recommended to conduct thorough quality checks and standardize the production process to ensure consistent results.

2.6. Metakaolin

Metakaolin is a highly reactive pozzolanic material produced by calcining natural kaolinite clay at temperatures between 600-800°C. Its application in concrete, especially as a supplementary cementitious material, has garnered significant attention.

A study has indicated that the inclusion of micron-sized metakaolin significantly enhances the compressive strength of recycled concrete. However, the increase of concrete compressive strength decelerated as the metakaolin content increase. In addition, metakaolin has better effect for recycled aggregate concrete. Especially for replacement rate of 30%, the compressive strength increase reached 17% [9].

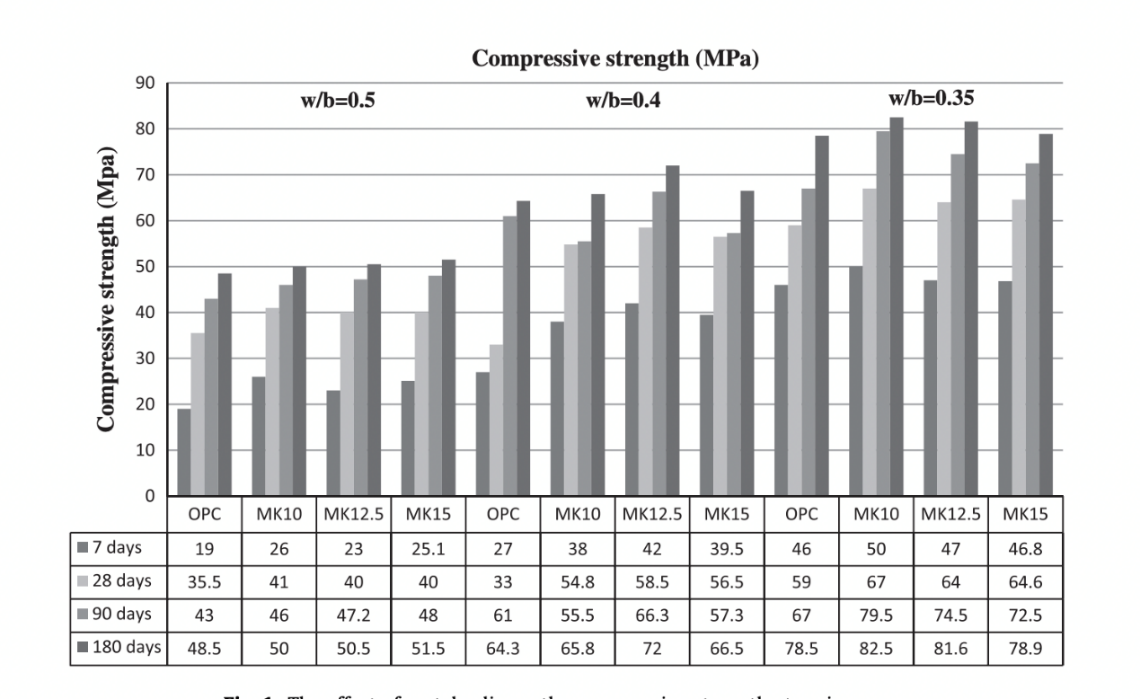

Another investigation into the influence of metakaolin as a supplementary cementitious material on the durability of concrete showed similar result that metakaolin can promote the compressive strength of concrete. Furthermore, it also investigated the effects of metakaolin for concretes with different water/binder ratios and found that the positive effect is maximized and reached 26% increase for 180-days concrete with 35% of water/binder ratio and metakaolin replacement rate of 10%, as shown in figure 3 [10].

Figure 3. Compressive strength of concrete containing metakaolin at various ages [10].

The utilization of metakaolin as a cementitious material in concrete presents clear advantages. It not only elevates the compressive strength of the concrete but also fortifies its durability. Given considerations of sustainable resource utilization and long-term performance of concrete, the utilization of MK is poised to play a significant role in future concrete technologies.

3. Discussion

3.1. Common features

All the materials discussed in this paper, from basalt fiber to metakaolin, exhibit a key characteristic: they possess inherent properties that allow them to interlock, bond, or interact with the cementitious matrix in a manner that boosts the overall strength of the concrete. The integration of these materials into the concrete mix often results in microstructural refinement, leading to a denser and more cohesive matrix.

For instance, basalt fibers, with their high tensile strength and modulus, provide effective stress transfer between the concrete matrix and the fibers. Similarly, metakaolin, being a highly reactive pozzolanic material, undergoes secondary hydration reactions, filling voids in the matrix and reducing porosity. These mechanisms underline the primary reason for the enhancement in compressive strength.

3.2. Production

The production of these materials is a significant aspect to consider. Sustainable production methods can add another layer of value to these materials. For instance, RHA is a byproduct of rice milling, making it an eco-friendly material. Similarly, Robo sand, glass sand, and CMA provide avenues for waste management and recycling, turning potential environmental liabilities into assets.

However, while materials like metakaolin require energy-intensive calcination processes, the overall benefit, in terms of enhanced concrete performance and durability, often outweighs the energy input. Future research could delve deeper into optimizing production methods to further minimize environmental footprints.

3.3. Lack of investigation on integration

An intriguing observation from the study is the potential diminishing returns or even negative effects when these materials are added beyond optimal quantities or in certain combinations. For example, while RHA and Robo sand individually enhance concrete’s compressive strength, their excessive inclusion can lead to a decline in performance. This suggests that there might be competitive or antagonistic reactions occurring at the microstructural level, warranting further investigation. Moreover, not all combinations of these materials have been extensively studied. The potential synergies or conflicts arising from mixing two or more of these materials remain an open area of research.

3.4. Application

The practical applications of these materials in real-world construction scenarios are vast. Given the enhanced compressive capacities, structures using these modified concretes could be designed with thinner sections, leading to material savings and reduced construction costs. Furthermore, the heightened durability offered by materials like metakaolin can translate to longer structure lifespans and reduced maintenance costs. In regions prone to environmental stresses, such as freeze-thaw cycles or aggressive chemical exposures, these modified concretes can offer superior performance. However, it’s essential to balance the benefits with potential challenges. For instance, while glass sand may offer specific advantages, its sharper texture might pose challenges in mix workability or finish quality.

4. Conclusion

In this paper, a variety of materials including basalt fiber, succinic acid, RHA, Robo sand, glass sand, CMA and metakaolin, and their impact on the axial compression capacity of reinforced concrete are analyzed. Each material offers different degrees of strength enhancement, with some also addressing environmental and sustainability concerns. Most of them also showed ability to absorb redundant chemical substance and help integration, which might be the reasons of improved strength.

These materials, while beneficial, must be optimized in terms of quantity and combination to guarantee their positive effects. There are existing gaps in research, especially concerning the combinatorial effects of these materials and their long-term performance. Future studies could focus on these aspects, aiming for a balance between different materials.

In summary, these materials, which can enhance compressive strength, present some common features, and their optimized integrations provide significant improvement toward compressive strength. These common features might be helpful for identifying material that can improve the strength of concrete, and the remarkable performance of these innovative materials also reveals the huge potential of non-traditional concrete.