1. Introduction

Urban sewage treatment can be traced back to ancient Rome. At that time, people just needed to think about the drainage issue because the water body's capacity for self-purification was sufficient to meet human need for water. Since many infectious diseases spread through home sewage with the growth of the economy, individuals started treating the water that was discharged. The water treatment project of late Ming Dynasty unearthed in Xikou village of Yongjia County is the earliest water treatment refining plant found in China [1].

China's economy has developed rapidly in recent decades, which has brought about the expansion of water pollution. There are many kinds of sewage treatment processes in China's cities, with different effects. At this stage, there are still many problems to be solved, such as insufficient construction funds, poor treatment effect and low utilization rate of water resources [2].

Qingdao has steadily transformed from a minor city to a new first-tier metropolis thanks to the rapid advancement of science and technology. As the population grows and the quality of life of the populace improves, more toxins are being released into the environment. Many citizens do not have a strong awareness of the protection of sewage polluted environment, and sewage treatment plants are under great pressure. Therefore, this paper chooses Maidao sewage treatment plant as an example to investigate and analyze the domestic sewage and garbage in Qingdao and the treatment technology.

Through field trips, expert interviews, data collection, literature review, and actual data analysis, this paper understand, analyze and research Qingdao's sewage treatment system's state of progress and future prospects. The main purpose of this research is to obtain basic data and information on the water quality and pollutant removal rate of the wastewater treatment plant, and to provide practical examples of how to control the treatment effect of the wastewater treatment process in detail. Another purpose of this research is to analyze the treatment status of the plant and suggestions for improvement were put forward for reference.

2. Current situation of sewage treatment

2.1. Different methods of sewage treatment

Generally speaking, there are three methods for urban sewage treatment: physical treatment, chemical treatment and biochemical treatment [3].

2.1.1. Chemical treatment. Chemical treatment method refers to the use of chemical agents and chemical reactions to separate the wastewater from various pollutants in the wastewater collected at the same time and convert them into harmless substances through chemical reactions with the wastewater.

2.1.2. Physical treatment. Physical treatment is the most basic method to treat industrial wastewater. It uses physical or mechanical separation to treat sewage. The common methods are filtration, sedimentation, centrifugal separation, etc.

2.1.3. Biochemical treatment. Less sludge excess, excellent treatment quality, a small floor space, and high sewage treatment efficiency are all benefits of the biological treatment method, which can handle the rising trend of urban sewage discharge. Therefore, the biological treatment process has gradually become the most widely used process [4].

The dissolved and colloidal organic contaminants in the sewage are broken down and transformed into innocuous chemicals by microbes using their metabolic activity, which allows the sewage to be cleansed. The methods are mainly divided into aerobic oxidation method and anaerobic reduction method. Oxidation ditch method, SBR method, A2/O method and AB method are often used in the secondary treatment process of urban sewage [5].

3. Case analysis

3.1. Background of the plant

Maidao sewage treatment plant has the highest treatment capacity per unit area in Qingdao. The plant processes 140000 tons of sewage per day and plans to expand to 220000 tons in 2024. The project is located to the east of Mai Dao Road, Lao Shan District, to the south of Donghai Road, and the original Mai Dao sewage plant. The project's entire construction area is 33921.78 square meters, of which 9317.99 square meters are above ground and 24603.79 square meters are subterranean [6]. The construction content is the production and office buildings of the sewage plant, including the popular science exhibition hall open to the public and the overhead walkway connecting to the seashore. The finished Qingdao Mai Dao sewage treatment facility will significantly enhance the local water environment, reduce water pollution, and safeguard the water quality and ecological balance of the nearby basin.

3.2. Analysis of waste water

The data of the sewage treatment plant inlet or outflow water and removal rate are shown in table 1 in accordance with the class I-A discharge standard of pollutants for municipal wastewater treatment plants (GB18918-2002) and an interview with the management of the sewage treatment plant.

Table 1. Water quality and removal rate data of the plant.

COD | BOD | SS | TN | TP | NH3-N | |

Inflow water quality (mg/L) | 500 | 200 | 200 | 55 | 5.5 | 40 |

Outflow water quality (mg/L) | 50 | 10 | 10 | 15 | 0.5 | 5 (8) |

Removal rate (%) | 90 | 95 | 95 | 72.7 | 91 | 87.5 (80) |

4. Sewage treatment process

4.1. General process

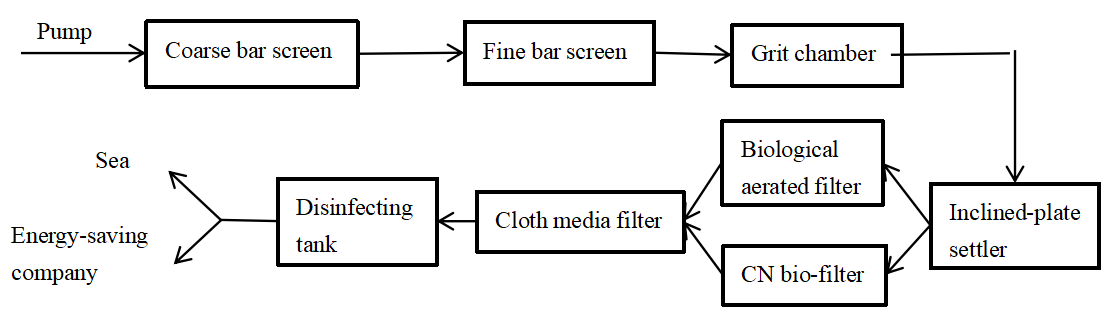

Sewage is mainly collected in Mai Dao sewage treatment plant by gravity. And the general treatment process can be seen in Figure 1.

4.1.1. Pretreatment and Primary treatment part. The primary treatment of sewage is mainly for suspended solid pollutants in sewage. Therefore, due to the natural advantages of solid and liquid, we often use physical methods in the primary treatment process [7].

The sewage is first filtered out of large particles of solid through the coarse screen, and then sent to the sand water separator through four inlet pumps. Next, the sewage will screen out small particles of solid through fine screen, and then part of the gravel will be removed through the grit chamber. Next, flow the sewage into the inclined plate sedimentation tank and add chemicals to deposit the suspended solids.

4.1.2. Secondary treatment part. The secondary sewage treatment mainly removes colloidal substances in sewage and organic pollutants dissolved in water [7]. After this level of treatment, it cannot meet the sewage discharge standard in China, so after that, there will be three-level treatment of sewage. The sewage is first introduced into biological aerated filter and CN biological filter, and then the biological rotary table is used for advanced treatment.

4.1.3. Additional treatment part. The dosing method is also used for disinfection. After the above treatment steps, the sewage will be sent to the ocean or energy saving company.

Figure 1. General treatment process of the plant.

4.2. Pretreatment process

4.2.1. Coarse bar screen. The coarse grid is responsible for removing large volume impurities with a clearance of 2cm. Mainly remove stones and wood blocks.

4.2.2. Sand water separator. A screw device for mixing is included with the sand water separator. From the top of one end of the separator, the sand water mixture is fed into the water tank. The spiral blades will drive the big specific gravity sand particles into the groove at the bottom of the mixed liquid. After exiting the liquid level, the sand particles continue to migrate for a given distance after being hoisted along the bottom of the inclined U-shaped groove. The water separated from the sand is discharged from the overflow port once the sand particles have fully dehydrated and are then discharged to the sand bucket through the sand discharge port [8].

4.2.3. Fine bar screen. The original fine grid with 6mm clearance was adopted in the sewage plant, and then the 5mm leakage mesh plate with internal inflow was improved.

4.2.4. Grit chamber. The grit chamber is divided into upper and lower scrapers, and the sand is lifted by the sand pump to separate the sand and water.

4.2.5. Inclined plate sedimentation tank. Inclined plate sedimentation tank is used to remove suspended particles, carbon pollutants and phosphorus pollutants in sewage. The coagulant and high molecular flocculant added to the sewage contact with the organic suspended solids to form alum, which settles when the water flows through the inclined plate and slides down to the bottom of the tank under the action of gravity. The precipitated sludge is concentrated and partially refluxed to avoid excessive dosing and improve the sedimentation [9].

4.3. Primary treatment

4.3.1. Biological aerated filter. Biological aerated filter (BAF) is mainly divided into three types: BIOFOR, BIOCARBONE, BIOSTYR [10]. The step here uses BIOSTYR aerated filter. The biofilm was supported by polystyrene spheres of equal particle size. The outer layer of biofilm is auto-trophic bacteria for nitrification. When water flows through the biofilm, ammonia nitrogen is oxidized to nitrate by bacteria. The inner layer of the biofilm is heterotrophic bacteria for denitrification. When water flows through the biofilm, nitrate becomes nitrogen and leaves the system [10-12]. Filter materials are divided into light filter materials and planting filter materials. Currently, volcanic rock, ceramsite and other materials are used as filter materials.

4.3.2. CN bio-filter. The newly-built 14 grid 10m x 7m ABAF nitrification filter and the original BIOSTYR nitrification filter operate in parallel, with the main function of removing carbon source and ammonia nitrogen. A new ABAF nitrification filter is to be built, and the filter material is a special biological filter material with a diameter of 2.0mm -5.0mm. The thickness of filter material layer is 4.0m. The sewage flows into the water distribution layer through the inlet pipe, and then enters the biochemical reaction area through the filter head. The filter head is responsible for evenly distributing the inlet water into the filter material layer, and carrying out the biochemical reaction in the aerated environment to remove COD, SS and ammonia in the raw water.

4.4. Secondary treatment

4.4.1. Cloth media filter. Filter cloth filter is to use filter cloth with a certain aperture to remove suspended solids, so that the suspended solids and turbidity indexes in the water can meet the standards of sewage discharge or recycling [13].

4.4.2. Disinfection tank. Because the daily treatment water volume of the plant is large and the water flow rate is very fast, ultraviolet disinfection cannot completely kill all viruses. Therefore, the disinfection process of the plant was improved from ultraviolet treatment to dosing treatment of chemical substances such as sodium hypochlorite.

4.5. Sediment treatment

Biogas is generated for power generation through nitrification tank. Due to the heat dissipation and flue gas heating of the motor itself, the water temperature is kept at 35-40 ℃, with strong microbial activity and fast treatment. After sediment dewatering, cationic flocculant is added for centrifugal dewatering.

4.6. Tail water discharge

Cecep and reclaimed water company take water for greening irrigation, and the rest is discharged into the sea. The factory built a 1000-meter-long deep-sea water pipe for discharge.

5. Suggestions for improvement on recycling

As a resource-based water shortage city, Qingdao has 186.2 cubic meters of water resources per capita, which is 9.5% of the national average. According to this indication, Qingdao's absolute water shortage standard of 500 cubic meters per person is much below average for the country as a whole as well as the city. The reclaimed water utilization rate of Qingdao Maidao sewage treatment plant is only about 30%. A small amount of the reclaimed water is sold, and the majority is released into the ocean. Therefore, the large-scale discharge of the treated purified water into the sea by the plant should be improved [14].

5.1. Current situation of reuse water

Reclaimed water reuse in China got off to a late start, and it wasn't until the late 1980s that the practice and research of it started to be gradually promoted.

At present, the main uses of reclaimed water in China are municipal utilities, industry, agriculture, environmental entertainment and supplementary source water. According to the specific use purpose and water quality requirements, the facilities and technologies for water source and sewage recycling are also different [15-20]. Qingdao Haibohe sewage treatment plant and Yan'an west road sewage treatment plant use part of the purified water for toilet flushing, irrigation and washing.

5.2. The significance of urban sewage resource utilization

The utilization of sewage resources helps to improve the urban water environment, reduce the discharge of pollutants, and thus reduce the pollution load on the water environment.

5.3. Reclaimed water treatment for different purposes

5.3.1. Irrigation, washing, and construction water. For such non drinking domestic water, we can directly use the treated sewage. In addition, some process water and cooling water in industrial production can also be directly used, reducing the use of tap water and groundwater, reducing water costs for enterprises, improving production efficiency and product quality, while also protecting the environment and reducing the impact of pollution discharge on the environment.

5.3.2. Hydroelectric power generation. The tail water energy resources of sewage treatment plants are very abundant, and the tail water drop can be used for hydroelectric power generation. On June 6, 2022, the first demonstration project of a city-wide wind, solar, and water multi energy complementary power station in China, located at Yangluo Sewage Treatment Plant in Xinzhou District, successfully generated electricity. This is a highly promising field of renewable water utilization. The use of treated water for power generation is a developing trend [20].

5.3.3. Drinking uses. Although China has not yet implemented the use of reclaimed water resources for drinking, other countries have done so. For example, Windhoek in South Africa and chanoute in Kansas in the United States have not found any health problems yet. But for the sake of insurance, it is generally accepted that drinking recycling is not the main consideration [15].

6. Addition of a regulating tank

It is simple to create the issue of too much water pressure during the day or high energy consumption at night due to the varied amounts of waste water created by inhabitants in the morning and evening. The establishment of a regulating tank can control the inflow of sewage treatment, cut the peak and fill the valley, store water during the day and treat it at night.

7. Conclusion

Nowadays, the sewage treatment technology in the world is developing very rapidly, with various types and different treatment effects. Numerous issues with sewage treatment have arisen as a result of China's rapid advancement in science and technology, including poor technology choice, a lack of funding, a lack of qualified personnel, and others. Urban sewage treatment is often neglected by inhabitants. The goal of this study is to increase awareness of and understanding of the current state of urban sewage treatment. This paper selects the actual situation of Qingdao Maidao sewage treatment plant in Shandong Province for analysis. Firstly, the types and applications of common sewage treatment technologies are analyzed, and then the pollutant removal rate is calculated according to the actual inlet and outlet water quality data of Maidao sewage treatment plant, and its working efficiency is analyzed. Next, the equipment used for pretreatment, primary treatment, secondary treatment and tail water treatment are introduced respectively, and the processes and effects of various treatment processes are further explained. In addition, this paper also makes an in-depth analysis of individual problems, introduces the development of reclaimed water in detail according to the characteristics of water shortage in Qingdao, and puts forward effective suggestions for improvement in the refinement of treatment process and the reuse of water resources.