1. Introduction

Fatigue drive is an important factor in the cause of traffic accidents and the harm that it causes is serious; fatigue can cause the driver’s physical fatigue, especially will cause the acidity and swelling of the eyes, making physical discomfort to affect the driver’s work, and subsequent fatigue will also reduce the attention and reaction of the driver, this effect will make it impossible for the driver to make timely braking behavior when encountering an emergency and cause dangerous serious traffic accidents and which has caused a wide range of researchers [1]. Currently, the main direction of detection and prevention of fatigue driving is by extracting driver’s facial characteristics or detection of brain signals, for example, ROC curve analysis of eyelid diameter deduces the fatigue state of the controller, Viola-Jones face detection technology [2]. But this is limited by algorithms and hardware, and the technology for detecting tiredness driving is not yet mature. Human body and face will have noticeable characteristic changes when entering sleep, especially in fatigue state, this change will become more obvious. Therefore, according to the changes in human physical characteristics when people get into sleep due to excessive fatigue, an instrument can be designed to detect the dry body and body end characteristics of the driver to assist in detecting the fatigue drive by capturing driver’s face characteristics. This will provide a new feasible solution to the problem of fatigue driving and improve the accuracy of the detection method. By detecting the grip of the driver’s fingers and steering wheel, as well as the pressure of the seat and back, it can complement this method of detecting drivers’ face characteristics, making detection and prevention of Fatigue driving more accurate and effectively protecting the driver and passengers. Therefore, the physical aid needs to be divided into two parts, the first part is the steering wheel, and the second part is the seat. In the design of the steering wheel, it is required that the steering wheel equipped with pressure sensors will not cause additional influence on the driver. In addition to the requirements of the design of the seat, in addition to the requirements that do not cause additional influence on the driver, the additional requirement that the seat is ergonomic so as not to cause discomfort to the driver and cause fatigue. Since it involves attitude detection of the driver, there is a trade-off between two mainstream approaches. One is to record the driver’s dynamics and posture through a camera instrument, which is analyzed by the computer in real time. The other is to analyze through sensors, in which sensors are divided into two categories, one is a device worn by a person, and the other is feedback through contact with the human body. Although the camera equipment can detect the human posture more accurately, the camera has a certain volume and is not suitable for driving scenes [3]. Wearable sensors, too, abandon this method because of their easy interference to the driver. General force sensors are mostly cylindrical and not easy to install on steering wheels and seats, so the ideal solution is to achieve attitude and force detection through membrane force sensors to complete the supplement to facial feature detection.

2. Research and Design

2.1. Survey and Investigation

According to the statistics of road traffic industry survey, the proportion of accidents caused by fatigue driving in heavy traffic accidents reaches more than 40%, which is one of the three major causes of heavy traffic accidents and accounts for as much as 21% of the fatalities caused by traffic accidents. In order to solve the problem of fatigue driving, collecting the driver’s facial features in the driving state is now one of the mainstream directions, but limited by equipment and technology, need to be assisted by other methods, such as force sensors and visual equipment to detect the driver’s grip, posture, with the seat to analyze the driver’s force.

Through experimental investigation and comparison, it is found that the driver’s grip on the steering wheel can be significantly different between the sleep state and the normal state. Under normal driving conditions, the driver’s grip force is basically maintained at about 5000g, while after entering the fatigue state, the driver’s grip force will drop to 50g or even 0g [4]. Therefore, it is effective to add force sensors to the steering wheel at three o’clock and nine o’clock directions of internal measurement to detect the human hand grip force to assist facial recognition to determine the driver’s fatigue state. At the same time, the driver’s hand posture tends to change significantly in the fatigue state, for example, the fingers may unconsciously stop holding the grip. In such a situation, the inner side of the steering wheel will not be subject to force, so the installation of force sensors on the inner side of the steering wheel can effectively detect fatigue driving.

Seat can also assist in the detection of fatigue driving, based on the ergonomic analysis of car driving, the driver’s human posture analysis can be divided into spinal posture and force analysis. In the spinal posture analysis, the fatigue state of the driver’s spine may be out of the seat back or the back of the head will be close to the seat back, and the normal state of the spine fit the seat back and head out of the seat has a significant posture difference, and these two fatigue postures will lead to the seat back and head pillow force increase, respectively [5]. Therefore, adding force sensors to car seats is also a way to detect and prevent fatigued driving.

While detection and prevention is certainly a solution to fatigue driving, making anti-fatigue designs at the time of the car’s design can also effectively reduce the number of car accidents caused by fatigue driving. For example, appropriate seat height, reasonable seat cushion pressure distribution, and excellent seat vibration resistance will make the driver in a comfortable driving environment to reduce their fatigue [6].

2.2. Product Design and Model Structure

The specific ideas and designs are as follows:

Because the auxiliary equipment is monitored by physical methods to the driver, so there is inevitably a certain physical volume, and too heavy equipment must hinder the driver’s driving environment, cause driver discomfort, or lead to other driving accidents, so in the selection of equipment is selected film sensor and micro refrigerator (like the size of mobile phone radiator), in order to allow the membrane sensor to accurately monitor the driver’s pressure on the seat and steering wheel in real time, the membrane sensor cannot be too far from the contact surface Therefore, the inside of the leather surface is the ideal mounting position for the thin-film sensor. Based on this, in the design of the steering wheel, the membrane sensor is installed on the inner diameter of the wheel rim of the steering wheel of the car; In the driver’s seat, membrane sensors fit into the backrest and cushion of the seat and are installed in the seat with padding such as sponge. This design not only does not have additional impact on the driver’s operation, but also has good real-time and continuity in monitoring the driver’s signs.

In addition to meeting the functional requirements of the seat and steering wheel, it is also necessary to meet the requirements for comfort. Since the steering wheel does not have the need to delve too deeply into the design, only the seats are involved in the physical design of the assistance system. Car seat cushions should be designed with the back and hips to provide reasonable support for the driver. The general sitting posture is divided into two types, one is only one support point, that is, only the hips are in contact with the seat, and the second is that there are two support points, that is, the hips, and the back is in contact with the seat. Because the prerequisite for detecting the driver’s posture needs to be met, two support points are selected as objects in the design of the seat [7]. The comfort level of the human body can be expressed by the pressure on the seat. The common material chosen for car seat fillers is sponge, which can cause uneven force, so hardened combined car seats can replace conventional car seats [8]. At the same time, because of the uneven pressure, the modular design of the seat can provide better comfort for the driver, and the modular design form can also better fit the physiological curve of the human body, so that the force sensor can more accurately perceive pressure changes and monitor the results more accurately [9].

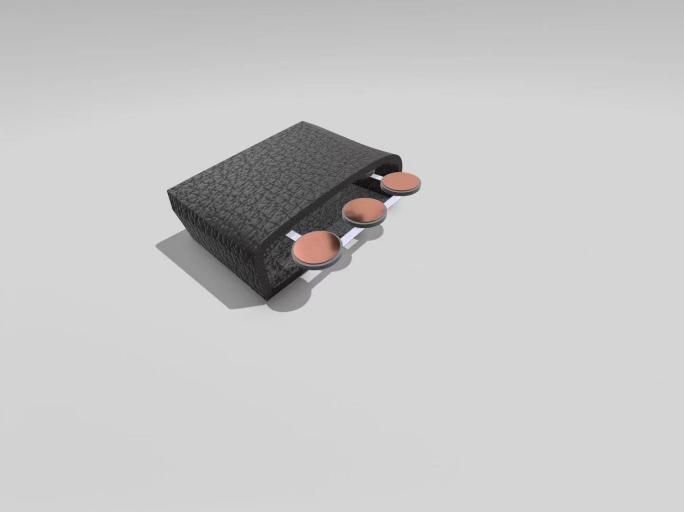

As shown in the Figure 1 below, these two are schematic diagrams of the cross-section of a car cushion fitted with a thin-film sensor.

Figure 1: Schematic diagrams of the cross-section of a car cushion fitted with a thin-film sensor.

3. Discussion

Specifically, installing thin-film force sensors on steering wheels and seats is a useful auxiliary method to detect facial features and prevent tired driving. At the same time, it can continue to add more functions to the device, such as alerting the driver, adjusting the driver’s temperature to prevent fatigue and other functions. To prevent fatigue by regulating the driver’s body temperature, for example, when the human body is stimulated by cold, the cold receptors in the skin will generate excitement and transmit the excitement to the hypothalamus thermoregulation center, which will then excite relevant nerves, thus causing the skin blood vessels to shrink, reducing the blood flow of the skin and reducing the heat dissipation of the skin. At the same time, skeletal muscle produces involuntary shivering, adrenal secretion activity is strengthened, adrenalin secretion increases, metabolic activity is enhanced, heat production increases, human body is more excited, and more rapid response, so as to prevent fatigue driving. In addition to prevention, alerting tired drivers is an essential feature of the device. It is possible to alert the driver by vibration. When the detection system detects that the driver is in the fatigued driving state, the seat sends a signal to the vibration system, and the seat starts to vibrate to wake up the driver. After the driver is awake, the vibration amplitude is reduced until the driver stops. However, the vibration of the seat in this scheme may affect the driver’s control, so the scheme of adjusting the temperature can be used to wake up the driver. The principle is the same as that of the vibration scheme, but the way of awakening is changed to reduce the temperature of the seat and steering wheel. Although the scheme has a good prospect in solving the problem of tired driving, the detection system is also limited by the precision of the thin film force sensor. Due to the limitation of the precision of the thin film force sensor, it is difficult for the system to classify the driver’s attitude detection and force detection to judge whether the driver is in a state of fatigue, resulting in errors. Therefore, the detection system needs to be improved to meet the requirements of accuracy and real-time. The piezoelectric film vibration sensor has better conduction property than the ordinary film sensor, its flexibility, heat resistance and corrosion resistance, in the complex application environment will make its applicability in this scheme design has a better application, therefore, in the follow-up experiment will consider the use of the sensor for testing [10].

4. Conclusion

According to statistics, traffic accidents caused by fatigue driving account for 21% of the total number of traffic accidents in the country, and the mortality rate of traffic accidents caused by fatigue driving is as high as 83%. Therefore, the detection and prevention of drowsy driving has received more and more attention in recent years. Based on this, the purpose of this paper is to discuss the feasibility of a system that can assist facial feature acquisition to detect driver fatigue through physical detection of driver physical features, and to make a preliminary design. The main implementation method is to analyze and compare the physical characteristics of people before and after entering the sleep state, use a thin film sensor to obtain its changes, and judge the driver’s driving state according to the change of data, so as to detect whether the driver is in fatigue driving. The main work of this article is as follows:

(1) The existing fatigue driving detection method is analyzed, and it is concluded that the method of capturing the driver’s facial features cannot be continuously monitored, so it relies on adding film sensors to the driver’s seat and steering wheel to supplement the detection of the captured facial features and verify the feasibility of this scheme.

(2) In addition to the physical detection scheme, an additional reminder mechanism is added, which is initially set as seat vibration reminder and seat steering wheel cooling stimulation reminder, and finally selects the second method as the reminder mechanism by comparing the advantages and disadvantages of the two methods and the driving impact on the driver.

Although the feasibility of using thin film sensors has been determined in the direction of assisting in detecting fatigue driving, the direction of the reminder mechanism remains to be explored, and cold stimulation has an excitation effect on the human body, but the degree of enhancement of this method on the driver who enters the fatigue state is currently to be studied, so the method is currently only a more ideal design, and experiments need to be designed later to improve the reminder mechanism of the degree of action of the human body.