1. Introduction

As digital transformation becomes imperative, certain manufacturing companies are proactively developing tailored digital solutions for their users, driving their own transformation and value creation [1]. These digital solutions leverage digital and intelligent technologies to reshape user relationships, internal processes, and value propositions, thereby ushering in new intelligent business models and data-driven value chains [2]. Advanced manufacturing companies such as General Electric, SKF, and Siemens have achieved digital transformation and changed their business models and value creation logic by developing various digital solutions for their users [3]. However, many enterprises, in this process, prioritize technology over users, leading to a failure in providing ecological solutions and creating additional value for their users. Consequently, there is a significant investment with little return, causing them to fall into the “digital trap” [3,4].

Previous studies discussed the drivers, paths, and modes of enterprise digital transformation, and its impact on operational performance, business model adjustment or innovation [3,5,6]. However, they neglected how manufacturing enterprises develop and provide digital solutions for their users, to innovate their value-creation logic. When doing so, enterprises are influenced by not only their own resources and capabilities, but also user scenarios [7]. Therefore, it is urgent for researchers to systematically and in-depth explore how to cope with various user needs and changes and create different types of digital solutions for them.

Previous studies also neglected the value and role of users in developing digital solutions, and the analysis of the development process by manufacturing enterprises [8]. Given the practical needs and theoretical gaps, this study will employ an exploratory case study method, adopting the perspective of “manufacturing enterprise-user”. The objective is to delve into the intricate process of “how manufacturing enterprises develop digital solutions under user value guidance”. By doing so, this study aims to contribute to the ongoing discourse on digital transformation and user value creation in the manufacturing sector.

2. Methodology

This paper focuses on a traditional Chinese manufacturing enterprise, adopting a longitudinal single-case study method. The case study is an empirical research method that is suitable for studying contemporary phenomena in real-life situations, especially when there is no clear boundary between the phenomenon and the situation [9]. The main reasons for choosing a single-case study were: firstly, a single-case study could collect rich data from multiple sources of evidence, obtain in-depth information on enterprise management, and help solve the problem of interest in this paper [10]. Secondly, considering the dynamism of the research situations and the complexity of the research question, a single-case study could provide thick descriptions of the phenomena, analyze and present the details of the research situations, the phenomena and the participants’ behaviors, deal flexibly with data involving multiple levels of analysis, and discover the theoretical laws hidden behind the complex phenomenon. The data sources of this study included existing literature, secondary data, and previous literature (such as online news, and observation reports). The core question explored in this study is “How do manufacturing companies develop digital intelligence solutions”.

3. Findings

According to the case enterprise’s practice experience, the enterprise platform digitalization solutions can be divided into two stages. The first stage (2013-2019) is characterized as the network-based platform digitalization stage, emphasizing user-centric digitalization. This stage utilizes digital technologies to achieve the digitization of production and processes, develops services for manufacturing management and processes, fosters enhanced user engagement and collaboration in production, and delivers intelligent home solutions through the platform. The subsequent stage (2020-present) is recognized as the scenario-based ecological digitalization stage. It shifts the focus towards leveraging existing data resources for innovation, realizing intelligence across production lines, work units, services, and overall production. This stage aims to provide users with comprehensive solutions based on specific scenarios, offering diverse digital modules or combinations tailored to various user needs. The overarching objectives include achieving service personalization, operational transparency, and the establishment of a scenario ecology.

3.1. Network-based Platform Digitalization (2013-2019)

In 2013, the enterprise recognized the transformative impacts and challenges of the Internet era on traditional business models. Recognizing that the conventional bureaucratic organizational structure no longer aligned with the evolving landscape of diversified and personalized user needs, the enterprise envisioned the necessity of constructing an open ecological platform. This platform aimed to facilitate direct interaction and value creation with users. Confronting the dynamics of both domestic and foreign markets, the enterprise identified an opportunity to address diverse user needs through network-based platform digitalization solutions. This strategic move also involved the establishment of an open platform-type organization, necessitating significant investments in manpower, resources, and finances. Through the above analysis, the enterprise embarked on the development of network platform digitalization solutions centered around users. Leveraging digitalization technologies, the enterprise aimed to digitize manufacturing processes and workflows, offering users a platform system for manufacturing management services and process workflows.

To develop network platform digitalization solutions, the enterprise raised fund, hired system development talents, and cultivated digital technology talents. Using these digital technologies, the enterprise accomplished the digitization of various product lines across both production and processes. Furthermore, the enterprise executed the digitization of after-sales services that complement production activities. Throughout this transformative process, the enterprise introduced the RDHY mode, instituted intelligent home solutions, and crafted the KOS platform to facilitate collaborative user engagement within the network platform digitalization framework. With substantial investments in both capital and talent, the enterprise successfully dismantled barriers associated with network platform digitalization. Empowered by digital technologies, the enterprise fostered collaborative manufacturing among users, achieving transparency in production processes and user services. This comprehensive approach resulted in a significant augmentation of the overall user experience, ultimately leading to an increased influx of orders for the enterprise.

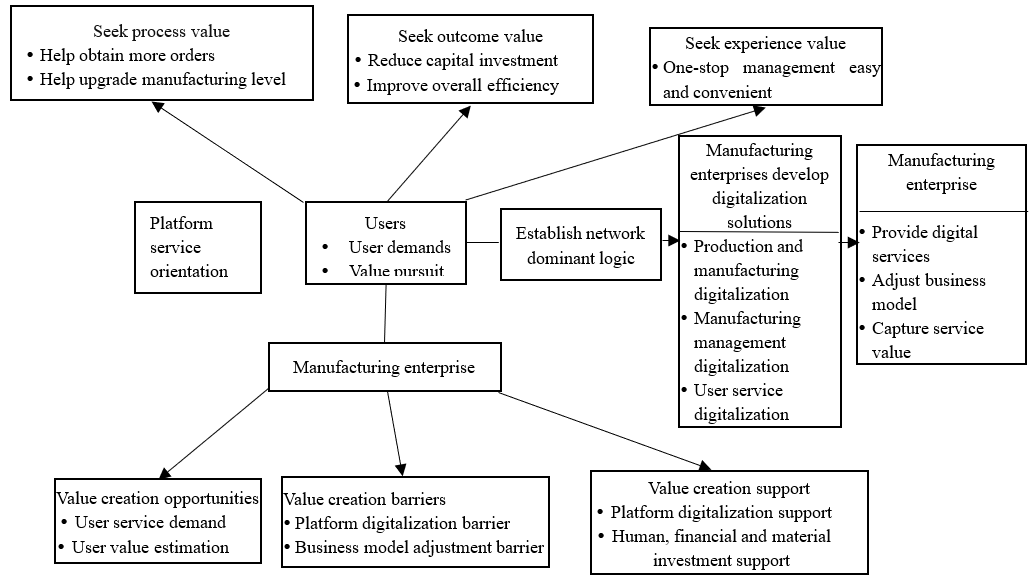

Figure 1: Network-based platform digitalization solution

In this stage, the enterprise identified the potential of utilizing digital technologies to achieve the digitalization of production and process workflows, aiming to enhance user participation in the manufacturing processes. This involvement would not only yield economic value for the users but also aid the enterprise in upgrading its manufacturing capabilities and streamlining process management, as illustrated in Figure 1. After understanding user needs and the value they seek, the enterprise conducted research to assess whether users could support the development and value creation of their service digitalization solutions. Additionally, the enterprise analyzed potential barriers it might encounter. To overcome the barriers associated with network-based digitalization, the enterprise conducted extensive testing and analysis on various product lines and production processes. Leveraging digital technologies, the results of these tests were transformed into data, and collaborative testing and development with users were initiated. Multiple production and manufacturing solutions were formulated to facilitate user-driven collaborative production. Concurrently, the enterprise hired a significant number of system development talents, established a user-centric value chain, and utilized the RDHY mode and KOS platform to achieve digitalization in collaborative manufacturing and process workflows. The enterprise provided digital services to users, aiding them in addressing challenges and faults promptly. By developing and offering digitalization solutions, the enterprise not only provided users with digital services, thus enhancing its manufacturing capabilities but also stimulated the sales of digital products. This marked a pivotal shift for the enterprise from a production-centric approach to a user-centric one, leading to significant adjustments in its business model. This transformation prompted changes in production processes and organizational structure, culminating in the establishment of the KOS platform to offer digital services to users.

3.2. Scenario-based Ecological Digitalization Intelligence (2020 - Present)

Since 2020, many manufacturing enterprises have been eliminated or switched to producing low-value-added products because they failed to produce intelligent and ecological products. Meanwhile, new capital such as smartphone and automobile manufacturers have entered the home appliance industry, often choosing to invest or cooperate with factories or foundries, focusing more on the return on investment and less on how to produce [11]. Based on the changes in users and user needs, the case enterprise realized the need to provide users with comprehensive digitalization solutions around scenarios, helping them create intelligent scenarios or upgrade to smart homes as a whole. To overcome the barriers to R&D (Research & Development) and integration of smart scenarios, the enterprise invested a lot of money and technology developers, collected user data through sensors, used IoT connection technology and AI distributed technology, and formed smart home intelligent systems through AI human-computer interaction systems, realizing intelligent interactive experience for users in all scenarios. At the same time, the enterprise also conducted in-depth interactions with users through the back-end RDHY and KOS platforms, accurately grasped user needs, solved user pain points, and jointly developed and implemented scenario-based ecological solutions with employees and users at all levels.

To develop a full-scenario ecological digitalization intelligent solution, the enterprise collaborates with multiple partners to collect and analyze users’ home data, tailor solutions for users, and develop solutions through continuous interaction with users. To break down barriers such as the diversity and complexity of full-scenario digitalization intelligence solutions, the enterprise selects pilot cities in a targeted manner, develops standardized digitalization intelligence solutions, and then adjusts them according to the specific conditions of users to form customized digitalization intelligence solutions. By investing a lot of manpower, material, and financial resources with its partners, the enterprise has developed 5 smart living spaces and 7 professional solutions. Users can choose to add or delete different intelligent modules according to their own needs. At the same time, the enterprise has also strengthened the sales and services of scenario-based digitalization intelligence solutions with its partners. While providing users with customized digitalization intelligence solutions, the enterprise will effectively copy and revise these solutions and sell them to other users, thereby reducing the cost of customized development and obtaining higher benefits.

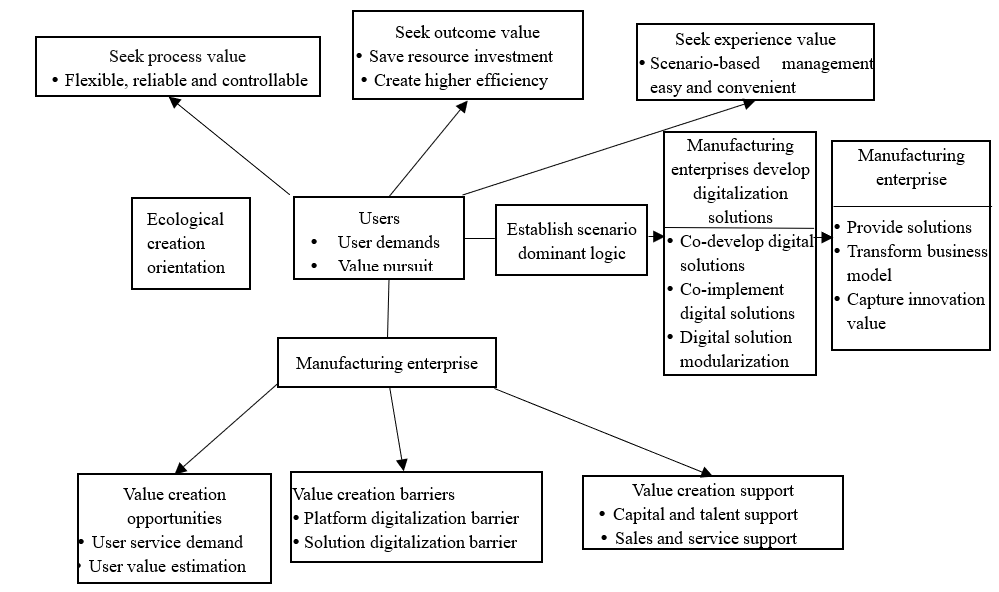

At this stage, the enterprise has recognized the huge changes in users and user needs. By integrating ecological resources, linking decoration, home furnishing, and home appliances into a cohesive scenario, and offering users one-stop services, it can help users customize full-scenario smart solutions, which enable users to obtain high-quality process value and experience value, as shown in Figure 2. After finding out the user needs and the value they pursue, the enterprise examines the target users to decide whether the value they deliver to users can sustain its own full-scenario digitalization solutions. Besides estimating the value-creation potential of the solution, it also investigates the obstacles to developing the solution. The enterprise has to collaborate with multiple partners, engage deeply in various activities, surmount difficulties such as low replicability of the solution, and demand strong talent and financial backing, to devise effective full-scenario digitalization solutions for users. During this process, the enterprise is changing its dominant logic, and starting to cooperate with multiple partners, to design and offer digitalization solutions based on “value”. It is making significant adjustments to its business model, broadening its boundaries and scope of operation, and concentrating on value management, in order to generate more and newer value for uses, and achieve value co-creation and sharing among multiple parties in this process.

Figure 2: Scenario-based ecological digitalization solution

4. Discussion

These findings contribute to the literature on digitalization transformation and user value creation in several ways. First, this study adopts an integrated manufacturer-user perspective to elucidate how user needs and sought value influence manufacturers in developing digitalization intelligence solutions. This provides insights on resolving the “digital intelligence paradox” between research and practice. The study reveals how continuous user demand changes affect manufacturers, clarifying that creating higher or newer value for users is critical for manufacturers in providing solutions to enable value creation. Manufacturers need a user-centric approach by understanding needs and helping create more value. Identifying user-sought outcomes, processes, and experience value enables recognizing digitalization opportunities and providing effective solutions. Manufacturers must also systematically assess value creation opportunities, barriers, and enablers to obtain sufficient resources while overcoming barriers. Analyzing the manufacturer-user angle in solution development helps resolve the paradox and avoid the “digital intelligence trap”. Second, this study explores how users play a crucial role in guiding solution development directions and contents, influencing value creation approaches, outcomes, and business logic. This contributes to research on solution development and enterprise logic transformation. Users’ needs and sought value lead manufacturer solution directions and contents, impacting value creation pathways, results, and even logic.

This study provides valuable practical implications for manufacturing firms undergoing digitalization transformation. First, the manufacturer-user perspective offers concrete measures to resolve the “digital intelligence paradox” and avoid the “digital intelligence trap.” Understanding how user needs and sought value guide solution development provides actionable steps for digitalization success. Manufacturing firms can leverage these findings to tailor digitalization solutions towards superior user value creation. Second, the extensive upfront analysis framework highlights how manufacturers can thoroughly assess user needs, sought value, digitalization opportunities, potential barriers, and organizational readiness before committing resources. Such diligent analysis clarifies value creation potential, enabling informed decisions aligned with user sought value. The study provides a roadmap for manufacturers to systematically analyze digital opportunities based on the manufacturer-user lens before embarking on the digitalization journey.

This study also has some limitations that can be addressed in future research. First, as a single case study in China, the findings may have limited generalizability. Future research could conduct comparative or multiple cases to achieve more robust results. Second, reliance on secondary data may miss nuanced process details. Future research could use primary data such as interviews or surveys to provide more insights. Third, the relatively short 8-year timeframe may not fully reflect longer-term enterprise logic and solution changes. Future research could use longitudinal data tracking evolutions over time to elucidate patterns and trajectories.

5. Conclusion

This paper addresses how the case enterprise uses artificial intelligence technology to develop digitalization solutions for users at various stages. Other enterprises can learn from this case enterprise and create value for users through different digital and intelligent solutions at different stages. The findings enrich the ways for enterprises to create and obtain value in a digital and intelligent environment and also have practical significance.