1. Introduction

The stratum corneum, epidermis and dermis are made up of three different layers in the skin. However, the existence of Arteries and veins, sweat glands, and hair follicles adds to its complexity. A layer of viable cells at the base of the epidermis is followed by a layer of terminally developed keratinocytes at the topmost layer. About 10 µm thick, the stratum corneum is a relatively narrow layer. Regarding the penetration process, the skin is a porous barrier with many semi-circular channels that range in diameter from 0.4 to 36.0 nm. The SC is the main obstacle that NPs must go through.

Because of the nanoparticles' tiny size, they may be absorbed into the skin and transport active ingredients to repair damaged areas of the skin, thereby increasing the efficacy of the product. Nanoparticles are used in the cosmetics industry to create sunscreens that protect the skin from UV damage, perfumes that last long, creams that work better against ageing and to make newly formulated makeup products more moisturizing.

In the early 1990s, Müller and Gasco provided lipid nanoparticles as a brand-new nanoparticle-based formulation [1]. LNPs are colloidal lipophilic systems made up of a monolayer of emulsifiers and the poly-based surfactant becomes a stable lipophilic nucleus in the aqueous phase. Additionally, more effective and focused target with significant side effects might be achieved by combining the creation of targeting LNs with a regulated stimulus release of the CAIs. They would be combined with the appropriate cosmetic active ingredient to improve their dissolution, stability, efficiency, and release, leading them to be used as sunscreen, antimicrobial agents, anti-acne, hair loss treatments, and other applications.

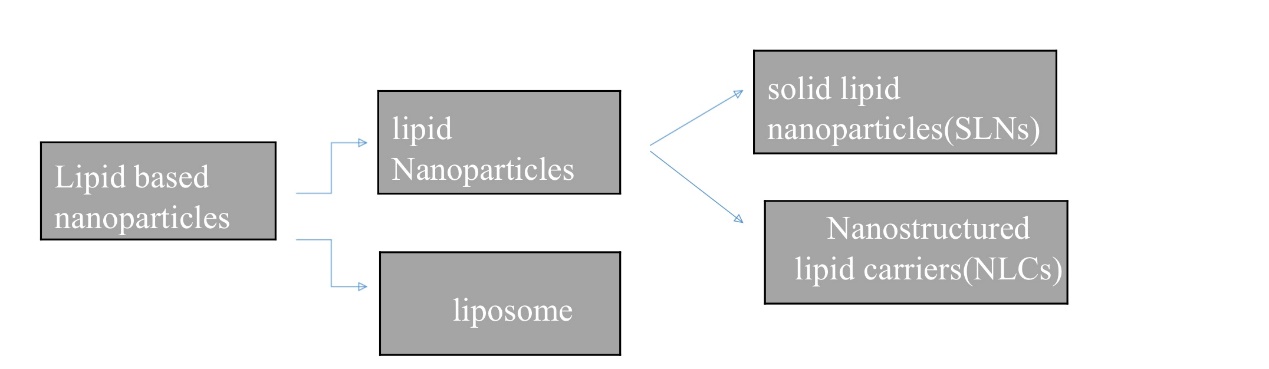

Lipid nanoparticles and liposomes are the two basic categories under which lipid-based nanoparticles may be categorized. Solid lipid nanoparticles (SLNs) and nanostructured lipid carriers (NLCs) constitute examples of lipid nanoparticles, as shown in Figure 1 [2]. The first generation of lipid-based nanocarriers, known as SLNs, are made from lipids, which are stabilized by emulsifiers and are solid at room temperature. NLCs are a second generation of lipid-based nanocarriers which are made of a combination of solid and liquid lipids, whose feature is an unstructured matrix due to the various moieties of their ingredients.

Figure 1. Classification of lipid nanoparticles.

2. Principle of lipid nanoparticles

2.1. Penetration

According to several researches, the skin serves as a significant entry point for nanoparticles [3]. The research suggests that there are three different paths by which nanoparticles might reach the skin: intracellular, transcellular, or transappendicular. The nanoparticles may then cross the dermis and epidermis on their way to the blood vessels. There are three primary skin penetration methods that may be categorized [4]: (a) The principal route for the majority of active components passes through consecutive hydrophilic domains in lipid bilayers. (b) The most advantageous route for lipophilic chemicals is through corneocytes and lipids (c) Skin appendageal transport is a key pathway for the Ionic permeability transport of ions and penetration of matter systems [5]. Moreover, Through hair follicles, which are a significant site for NPs transportation and gathering, the medicine can be delivered by the skin and dermal route in an intriguing method [6, 7].

2.2. Release of the active ingredients

The primary need before an action into the skin can be realized is the release of active substances integrated into SLNs and NLCs [8]. The process used to create the lipid nanoparticles, composition and concentration of surfactants, solubilizing capacities of the surfactant for the added action, the ability to dissolve, and the quantity of the active ingredient will all affect the release profile. The definition of active ingredient release from SLNs is based on three models: homogeneous matrix model, active ingredient enhanced core with lipid shell and active ingredient enriched shell with lipid core [9]. The components may release under regulated conditions based on the sort of SLN that is created. While SLN with an enhanced core result for drugs in sustained release, A drug-enriched version of SLN exhibit burst release characteristics. The manufacturing temperature, emulsifier arrangement, and oil fraction integrated into the matrix of lipids all affect how well NLCs release active ingredients. NLCs can provide two active component release patterns. While the active components inserted into the core of the nanoparticles are delivered continuously, the active components in the shell are released by bursting. It is possible to define the continuous release of the active ingredients splitting between the water and lipid matrix, as well as the barrier action of the interface membranes.

3. Characteristics of lipid nanoparticles

3.1. Film formation on the skin and occlusion property

When in touch with surfaces, particles smaller than a micron exhibit adhesiveness. For both liposomes and polymeric nanoparticles, this characteristic has been established. Regarding lipid nanoparticles, Here have been claims that when 4 mg formulation is applied per cm2, around 4% of lipid nanoparticles with a diameter of about 200 nm should potentially form a monolayer coating. This mono-layered film's hydrophobic nature causes it to have an occlusive effect on the skin, delaying the loss of water brought on by evaporation. The variable degree of occlusion, determined by the size of the applied particles, has been established by experimental verification of moisture barrier qualities [10]. The improvement in the ingredient's skin penetration may possibly be a result of the occlusive qualities of SLNs and NLCs. After adding the active substance in both LNs and lipid microparticles, the amount of coenzyme Q10 and tocopherol was calculated by tape stripping methods. In contrast to injecting microparticles, the penetration of actives increased by 40% when using a nanoparticle system with a 200 nm diameter.

3.2. In vivo skin hydration

Skin hydration is enhanced following dermal application of formulations containing SLNs, NLCs or LNs because of the decreased water loss brought on by occlusion. An in vivo investigation was conducted by Wissing and Müller to examine the skin hydration impact following alternating between using a regular o/w cream and one that contains SLN for 28 days. The skin's hydration was much higher with the o/w cream containing SLNs compared with regular o/w cream.

3.3. Improved skin targeting and bioavailability of active ingredient

Occlusion generally encourages the skin's absorption of active ingredients. Comparing the usage of a Q10-loaded SLN suspension to isopropanol and liquid paraffin solutions revealed increased coenzyme Q10 penetration. To keep a cosmetic formulation from straddling the line between a cosmetic and a pharmaceutical formulation, cosmetic actives should settle in the skin but not have any systemic effects. Therefore, a specific amount of skin penetration is necessary, and the active ingredient in particular needs to be localized in the skin. The same is true for several pharmacological active ingredients, including corticoids. Skin thinning is reduced to a minimum when localization occurs in the top skin. Prednicarbate's targeting impact varied depending on the make-up of the SLN formulations that were employed. This can be explained in two ways:

1. The varied lipid compositions of the SLN may cause the medication to localize differently and interact with the stratum corneum's lipids differently. 2. The location of the drug within the particle varied depending on the nanoparticle composition. A significant fraction of the medication was concentrated in the prednicarbate particle's outer shell in this circumstance [11].

4. Cosmetic application for lipid nanoparticles—SLN and NLC as topical vehicles

4.1. Sunscreen carriers

SLNs are physical sunscreens that are more effective at blocking UV rays than emulsions. Molecular sunscreens added to SLN have synergistic UV-blocking properties. In order to retain the amount of protection, a formulation's molecular sunscreen concentration might be reduced. The SLN formulations are noticeably superior to the equivalent emulsions according to the wave scanning of the formulations, which include oxybenzone integrated into the matrix of lipids. While retaining the amount of absorption, the sunscreen's concentration can be cut by 50%. It seems that SLNs are an ideal carrier mechanism for sunscreen compositions since the addition of molecular sunscreens results in synergistic UV-blocking activity. The employment of NLCs-supported sunscreen can significantly enhance the system's sunscreen effect, lessen skin irritability, utilize less chemical sunscreen, and increase the system's compatibility and durability. In order to increase the stability of UVA/UVB sunscreen, lessen the irritability of these two sunwatches on the skin, and improve sunscreen's compatibility with other reagents for practical use, Liu studied the simultaneous coating of UVB sunscreen butyl-methoxydiphenylphthalomethane and UVA sunscreen methoxy-octyl cinnamate vinegar by NLCs [12]. By using a high-pressure homogenization technique, Ling et al. created two different types of UV absorbent NLCs coated with dibenzene-3 and p-methoxy-cinnamic acid octanoic vinegar [13].

The UV absorption capacity of NLC coated with sunscreen was superior to that of regular emulsion, according to the findings of a comparison between their UV absorption capabilities. Additionally, there was a decrease in the amount of photoisomerization of the coated sunscreen.

4.2. As extended-release carriers for perfumes

Lipid nanoparticles have the capacity to cover an active ingredient, as well as regulate an active ingredient's release. This prevents the skin from being stimulated by a large concentration of an active ingredient and results in an active ingredient that is released continuously. The formulation's composition, the active component's solubility, and the procedures used to create the lipid nanoparticles all affect how the product is released.

The benefit of delayed perfume release is that it allows for a once-daily application with effects that last for several hours. This was shown to be possible when lipid nanoparticles were used instead of conventional o/w emulsions. By using fragrances in SLNs rather than in oil, the release can be slowed down [14, 15]. Because of fragrance outer particle release, in the first three hours, Lipid nanoparticles and drops of oil both being released in the same manner. The evaporation from SLNs was postponed for the final ten hours. Only 75% of the SLN's perfume was released after 6 hours, compared to 100% from the emulsion [14]. Additionally, the administration of skin-applied insect repellents may benefit from this characteristic.

4.3. As a carrier of highly active ingredients

Many functional raw ingredients, such as coenzyme Q10, whitening agent 377, white diatrol, astaxanthin, and others, have high activity, unstable chemical characteristics, and are easily decomposed when exposed to light. This significantly affects their antioxidant, whitening, and anti-aging effects. Considering the anti-aging cosmetic, The dermis loses a lot of its suppleness as we age. Wrinkles develop when the skin that has been stretched by muscle activity does not return to its original smoothness. Lipid nanoparticles have a moisturizing effect improving skin elasticity, and they may play a crucial role in creating anti-aging solutions [16]. Additionally, it has been demonstrated that carnauba wax-decyl oleate NLC has photoprotective qualities both when employed as carriers for inorganic sunscreens and when they are active-free [17]. A recent study evaluated the anti-wrinkle effect of slnSLNs loaded with retinol palmitate. The findings showed that this formulation had the potential to encourage skin penetration, shield skin from UV deterioration, and become anti-aging cosmetic products [18]. NLCs may coat the active ingredient, improve the stability of the ingredient, and has a high loading capacity. Astaxanthin solid lipid nanoparticles were created by Li et al. who used a high-pressure homogenization methodology [19]. The Malvin particle size detector measured the NLC's particle size in astaxanthin for potential dispersion index to look into the compound's stability and release characteristics. This procedure resolved the astaxanthin's low water solubility issue and increased the compound's bioavailability. Mitriet al. prepared retinol-loaded NLC by hot and high-pressure homogenization method, compared it with nano emulsion They discovered that it had the benefits of controlled release and simple penetration into the deep skin, and did not participate in the body circulation and could be used in cosmetics [20]. Fatime et al. developed new formulations of NLC containing vegetable oil, supplemented with A-tocopherol [21]. Through 8-month stability research, these lipid nanoparticles and free nanoparticles demonstrated good antioxidant activity and stability in cosmetics.

5. Advantages and disadvantages

SLNs offer several profits, for instance, the potential to preserve drugs from severe environmental conditions, employing the homogenization method to promote large-scale synthesis to make it biodegradable. SLNs also have several drawbacks, including ineffective loading of drugs and sometimes due to storage circumstances, it has a possibility of drug ejection owing to crystallization [22]. These drawbacks are caused by the flawless crystalline structure of SLNs. NLCs were created to deal with the SLNs' drawbacks. Due to their irregular crystal structure, NLCs can load more drugs than SLNs and prevent drug ejection through the way which prevents lipid crystallization throughout the production and storage processes. Many cell signaling pathways can be activated or interfered with by SLNs. Therefore, it is crucial to investigate the biocompatibility and cytotoxicity of SLN. The fact that SLNs and NLCs may have cytotoxic effects suggests that further research should be done on this subject, which is currently an open question. The above views are summarized in Table 1.

Table 1. Advantages and disadvantages of LNs.

Advantages | Disadvantages |

Increasing skin hydration | Cytotoxic effects |

Increasing cargo penetration | Low payload for most cargos |

Suitable for transporting cargos which are hydrophilic and lipophilic | |

Moisturizing effect on the skin | |

Control and extend cargo’s release | |

Biocompatible |

6. Conclusion

In conclusion, it should be noted that SLNs and NLCs have been demonstrated to be good delivery systems for skin hydration in vivo. Novel carriers called SLNs and NLCs are created for the regulated release of cosmetic applications. By creating carrier systems, nanotechnology may effectively solve the skin's refractive issues with most chemicals, particularly hydrophilic ones. Different nanoparticles' applicability has recently been demonstrated. Lipid nanoparticle-containing topical preparations are thought to improve skin penetration and hence boost therapy effectiveness. Furthermore, skin administration of nanostructures has been reported to have target delivery, decreased systemic absorption, adverse effects, and sustained action. In order to generate multifunctional lipid nanoparticles for cosmetic use that have a wider use, more study is required.