1. Introduction

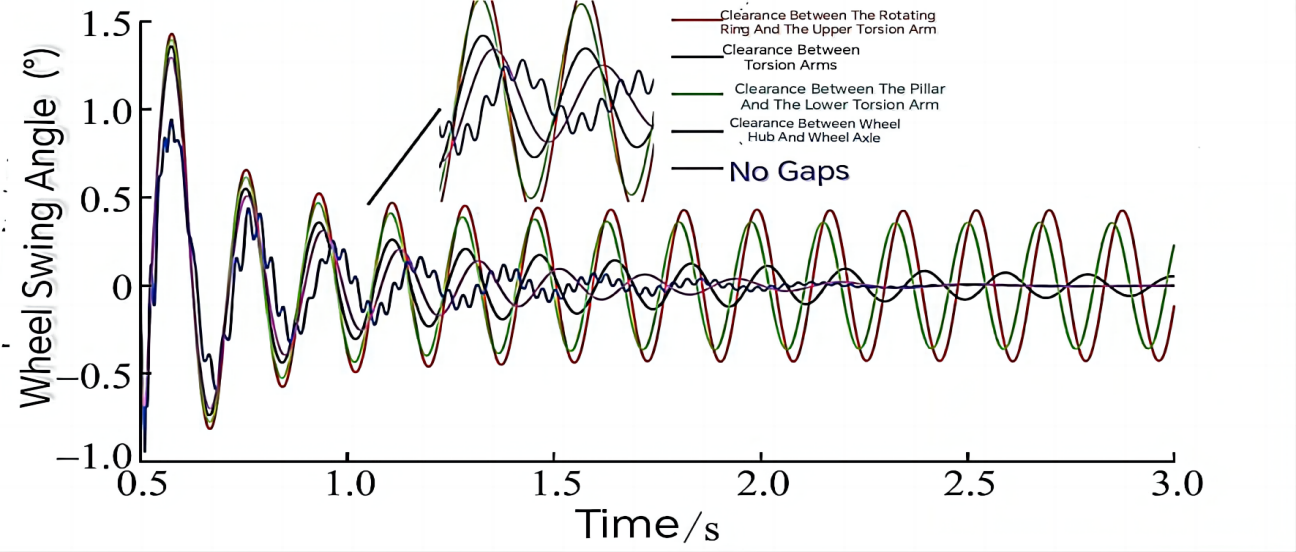

At present, the aerospace field has put forward more stringent requirements for materials such as lightweight, high strength, efficient thermal management, and high electrical conductivity, while carbon nanotubes have properties such as lightweight, high strength, flexibility, good planar thermal and electrical conductivity, and zero expansion. In the future aerospace field, it will be mainly used to reduce the mass of aircraft, improve the functionality and durability of aircraft components, and improve thermal control performance. Aviation wheels play an important role in the safe take-off and landing of aircraft and can easily affect the flight safety of aircraft and airborne personnel. Aircraft shimmy occurs after a period of use [1]. Due to the different mechanisms of aircraft wheel shimmy, studies have shown that the direct cause of induced shimmy may be caused by clearance (Figure 1). In addition, according to the latest research and application of integrated polymer composite materials, the computer simulation prediction of engine turbine blades shows that the addition of carbon nanotube to aircraft engine turbine blades can improve the strength, ductility and fatigue resistance of the blades to a certain extent. At the same time, with the development of carbon nanotube material preparation technology and the acceleration of the industrialization process, carbon nanotube has a place in many fields, such as structural enhancement, electrical and thermal conductivity, and electromagnetic shielding [2]. Therefore, the carbon nanotube can be regarded as one of the ideal materials in the field of aerospace.

Figure 1. Influence of different gap positions on wheel shimmy [3].

2. Properties and characteristics of carbon nanotube composite materials

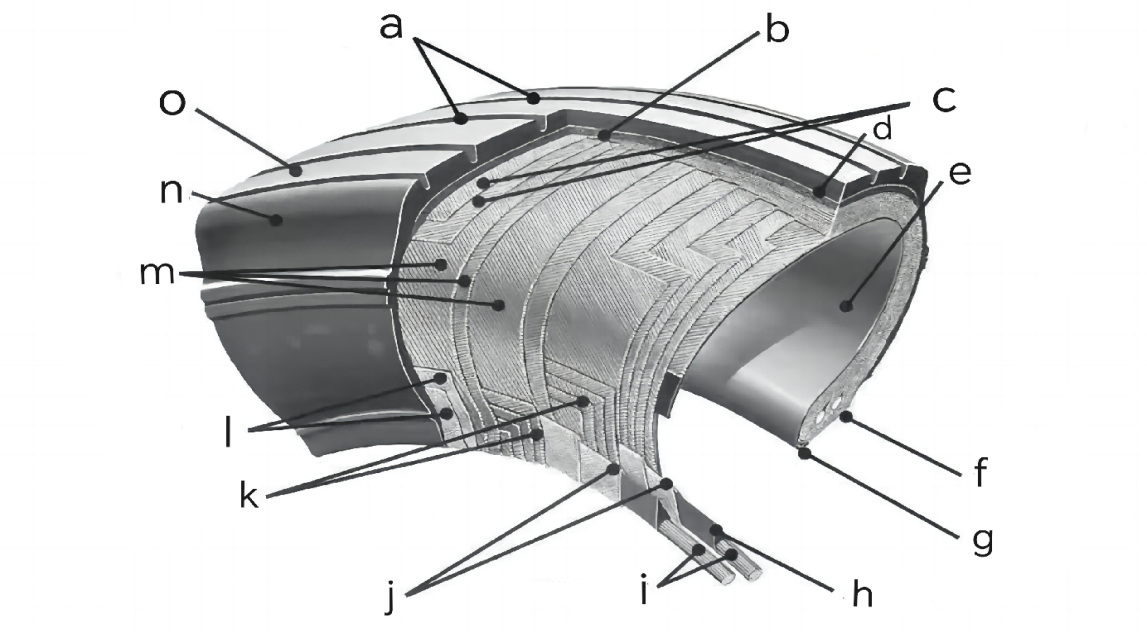

Nanometre material is divided into zero-dimensional nanometre material, one-dimensional nanometre material, and two-dimensional nanometre material. The carbon nanotube is one-dimensional nanometre material. Dimensional nanometre material has a perfect hexagonal structure and is light in weight [4]. Therefore, whether carbon nanotube is added to aircraft wheels, aircraft engine blades or made into touch screens in proportion, the weight of aircraft can be reduced to a certain extent. In addition, a carbon nanotube has good mechanical properties because the carbon atoms in a carbon nanotube are sp2 hybridized, and the s orbital composition is large, making carbon nanotube have high modulus and strength, and the structure of carbon nanotube higher than that of polymers [5]. The structure of the material is stable. Therefore, some engineering materials are used as the matrix and the carbon nanotube is mixed in a certain proportion, which can make the carbon nanotube composite material exhibit excellent fatigue resistance, toughness, knock resistance and scratch resistance [6]. At the same time, the strength can be greatly improved, the brittleness of the blades can be improved, and the service temperature of the material can be increased (Figure 2).

Figure 2. Scheme of the airplane blade [6]. a. GROOVES b. BUFF LINE CUSHION c. BREAKERS/BELTS d. TREAD REINFORCING PLY e. INNERLINER f. BEAD HEEL g. BEAD TOE h. APEX STRIP i. WIRE BEADS j. FLIPPERS k. PLY TURNUPS l. CHAFERS m. CASING PLIES n. SIDEWALL o. TREAD

3. Applications of carbon nanotubes in the aviation industry

3.1. Carbon nanotube composites as aircraft wheel material

The carbon nanotube is light in weight, high-pressure resistance, high-temperature resistance, wear resistance and high aspect ratio, which can be used as an important "pillar" in the structure of spacecraft. Carbon nanotube dispersion has a good reinforcing effect on materials such as metals, ceramics, and polymers. Studies have shown that when a multi-walled carbon nanotube with a mass fraction of 1% is added to polystyrene, the elastic modulus of the material increases by 36% to 42%, and the strength increases by 25%. Relevant data has shown that as the volume fraction of carbon nanotube increases, the hardness of the material shows an upward trend; when the content of carbon nanotube is 1.0% (mass fraction), the microhardness of the material increases by nearly 20%; the composite material prepared by adding carbon nanotube to magnesium alloy, its strength and modulus are increased [7-9]. In addition, the nanotube in polyacrylonitrile fibers are highly aligned, so the carbonized jelly-spun single-walled carbon nanotube/polypropylene wax nanocomposite material can reduce the thermal expansion coefficient of the material, thereby greatly improving the high temperature and high-pressure resistance of aircraft wheels, friction resistance, and thus greatly improve the safety of flight landing and taxiing.

When carbon nanotube is made into fibers, the carbon nanotube itself has the excellent characteristics of lightweight and high strength, and at the same time, has a fracture strain nearly 10 times that of ordinary carbon fiber composite materials, thereby enhancing the service life of the aircraft wheel and further reducing the aircraft wheel. Wheel repair and replacement costs. Other studies have shown that continuous carbon nanotube fibers are prepared by the floating catalytic method, and carbon nanotube is mechanically rolled to a certain extent. After mechanical rolling, the strength of carbon nanotube fibers can reach 3.76-5.53 GP, and the elongation can reach up to 8% ~ 13% [10]. And has ultra-high conductivity, and the compactness of CNT fibers is also greatly improved. It can be seen that the tensile strength, toughness and electrical conductivity of carbon nanotube fiber materials are significantly better than those of traditional high-strength carbon fibers. The latest research shows that super-strong carbon nanotube fibers are close to the ultra-long carbon nanotube with the theoretical strength of a single carbon nanotube, and the tensile strength of super-strong carbon nanotube can reach 80 GPa [11]. Carbon fiber in composite materials is mainly used in the aerospace field.

3.2. Carbon nanotube composite as aircraft engine blade materials

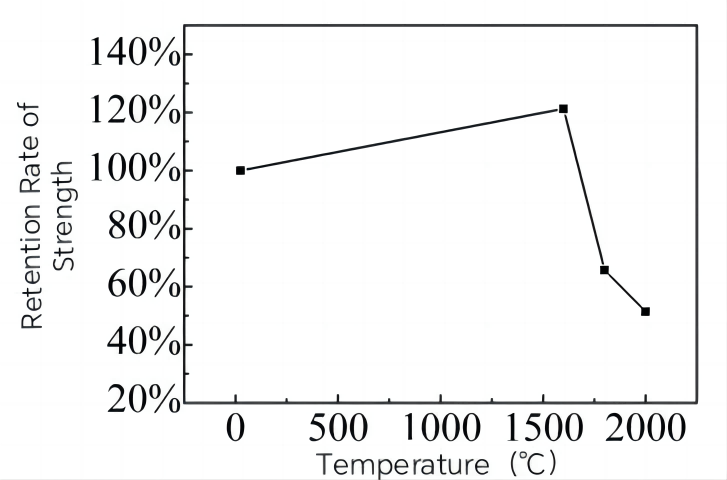

The main material of aircraft engine blades is ceramic matrix composites. Fiber ceramic composites mainly absorb energy through ceramic crushing and fracture and rely on the back plate to enhance the protection ability of ceramics. Because ceramics are easily broken when impacted, energy can be efficiently absorbed if combined with a tough composite backplane. The ceramic itself is passivated and has the function of transmitting impact loads (Figure 3).

Figure 3. Tensile strength retention of composites varying with temperature [12].

According to the above figure, relevant research indicates that as the test temperature increases, the tensile strength of the material first increases and then decreases. The material's tensile strength is the highest at 1600 ºC, reaching 121.22% of the normal temperature strength. If the temperature rises again, the material properties Then it drops rapidly [13]. At 2000 ºC, the material strength is only 51.43% of the strength at room temperature. The ceramic matrix composite material is prepared by the PIP process. The defect is that the preparation temperature is too high, and there is a certain difference in the thermal expansion coefficient of the matrix and the fiber [14]. The thermal expansion coefficient does not match. Cracks lead to a decrease in the bearing capacity of the material at room temperature and low mechanical properties. On the contrary, in the higher temperature range, the residual stress of this fiber and matrix is released, and the material properties are improved. Looking at the overall situation, the temperature of aircraft engine blades is related to the influence of the external environment and its own working state. In order to further ensure the safety of the aircraft, a certain proportion of carbon nanotube can be added to the engine blades to enhance its toughness and strength. According to the research on the microstructure's failure process, when the matrix's critical failure strain is smaller than that of the fibers, if there are large defects inside the matrix, the earliest failure mode of the composite material is matrix cracking. As the test temperature increases, the defects inside the matrix. It is increasingly obvious that the timing of material failure may gradually advance with the increase of matrix defects, resulting in the decline of material properties with the increase in temperature. In the high-temperature environment of 2000 ºC and a total duration of 3000 s, the tensile strength retention rate only reaches normal temperature, 82.4% of the total [15]. Therefore, adding carbon nanotube to aircraft engine blades can not only change the tensile stress but also enhance the toughness and fatigue resistance of aircraft engine turbine blades while reducing the weight of the aircraft, thereby reducing fuel loss during flight.

3.3. Carbon nanotube composite as display materials

Because carbon nanotube has a large aspect ratio, the heat exchange performance along their length is very high, but their vertical and radial heat exchange performance is very low, so carbon nanotube can be synthesized with different degrees of heat conduction materials and have good heat transfer performance and high thermal conductivity [16]. Adding a small amount of carbon nanotube to ITO can greatly increase the thermal conductivity of the carbon nanotube composite material, thus showing the sensitivity of the system. At present, Chinese stretchable manufacturing technology is still challenging, mainly in the development of high-sensitivity and stretchable strain sensors. One of them is a stretchable strain sensor based on overlapping carbon nanotube (CNT) bundles and silicon elastomers. The carbon nanotube strain sensor has a large sensing range (strain \( ≥ \) 145%), ultra-high sensitivity, and the characteristics of durability and repeatability [17]. In addition, the sensor performance will vary depending on the overlapping area of the carbon nanotube bundles. Therefore, adding a certain amount of carbon nanotube to the original display material of the aircraft can effectively improve the sensitivity of the display. Combined with the mechanical properties of the carbon nanotube itself, it can also enhance the anti-interference ability, waterproof ability, and knock resistance of the aircraft display ability and scratch resistance.

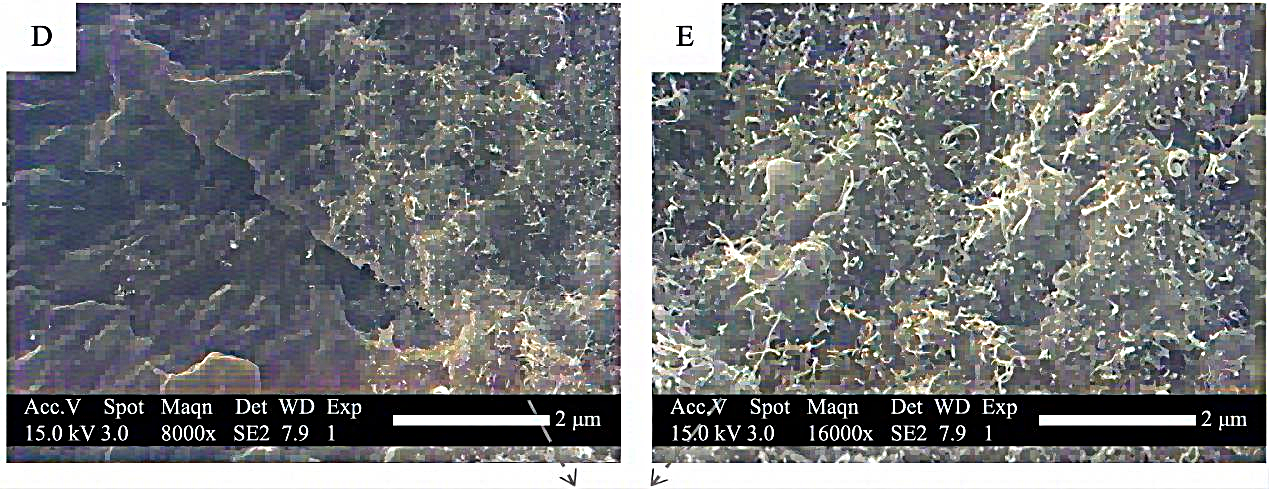

Secondly, the r-PP/PNTs composite material prepared by the melt blending method can meet the requirements of commercial electromagnetic shielding materials (Figure 4). Electromagnetic absorption loss accounts for 51.1%, and reflection loss only accounts for 15.2%. The electromagnetic shielding mechanism dominated by electromagnetic shielding efficiency can effectively avoid secondary pollution caused by reflected electromagnetic waves [18]. By constructing the conductive network particles in the cladding layer in the isolation structure, there are many interfaces between these particles, and these interfaces can achieve multiple reflection and absorption effects on the incident electromagnetic waves entering the interior of the material. At the same time, because the isolated conductive network structure formed is similar to a honeycomb structure, electromagnetic waves are reflected multiple times between the cladding layers, and it is not easy to escape and be absorbed [19].

Figure 4. SEM images of the r-PP/PNTs materials [18].

4. Application prospect and feasibility of carbon nanotube in the aviation field

The carbon nanotube can be used in electrostatic conductive coatings, electromagnetic shielding composite coatings, and stealth wave-absorbing coatings. In today's hot aerospace field, the carbon nanotube can be used as basic field emitters, sensors and transistors. According to relevant research, the above application prospects can be commercialized. The large-scale batch use of carbon nanotubes is currently difficult to control in the aviation field. Second, the preparation of carbon nanotubes is costly and time-consuming. Using different methods to prepare carbon nanotubes, the purity of the obtained pure carbon nanotube varies greatly. As one of the highest-strength fiber materials in the world today, the carbon nanotube is favored by researchers in various fields. It is the best time to study carbon nanotubes and apply them to the aviation field, and it has the greatest expectations for it [20].

5. Conclusion

At present, carbon nanotube has achieved good application research results in the fields of semiconductor devices, hydrogen storage, sensors, adsorption materials, battery electrodes, and catalyst carriers. Due to the light weight, high pressure resistance, high temperature resistance, wear resistance and other characteristics of carbon nanotube, as well as the characteristics of high aspect ratio, high modulus and high strength, the interaction between the molecular chains of carbon nanotube polymers is enhanced, thus making it. The mechanical properties are optimized; moreover, carbon nanotube can bind the thermal motion of polymer molecular chains, so that the integrity and stiffness of the polymer system can be maintained near a constant value, and at the same time, the strength of carbon nanotube composites can be strengthened. Resistance to shear deformation. Therefore, carbon nanotube has great application prospects in high-tech fields such as aerospace. But unfortunately, the application of carbon nanotube in the aviation field is only in its infancy, and it is expected to see effective results of carbon nanotube in the aviation field in the future.