1. Introduction

A display technique known as electronic paper, e-paper, or electronic ink display is designed to look like regular ink on paper. Electronic paper reflects light like normal paper, as opposed to a typical flat panel display, which illuminates its pixels using a backlight. Without using any electricity, it can store text and images indefinitely and allow for image changes in the future. E-paper can be created using a variety of technologies, some of which include a flexible display and a plastic substrate for the electronics [1]. Reading on e-paper could be more comfortable than on a traditional display because of the stable image, which doesn't need to be refreshed often, the wider angle for viewing, and the fact that it reflects ambient light instead of emitting its own glow. Direct sunlight won't cause the image on an e-paper display to appear faded while being read [2]. Although recently developed implementations are marginally better, the contrast ratio of displays currently on the market as of 2008 can be compared to that of a newspaper. To offer full-color capability, manufacturers are always competing. Applications include electronic price tags in stores, general signage, bus station schedules, electronic billboards, the Motorola FONE F3 mobile phone, and e-Readers that can show digital books and e-paper periodicals. Many applications [3] follow the concept of electronic ink display. One of the limitations of electronic paper is display backlighting, although the reflection index of electronic paper is very high compared to ordinary paper, making it easier on the human eye. Additionally, compared to flat-screen monitors, reading on electronic paper is more pleasant at an angle. The fact that electronic paper is made of plastic gives it the ability to be flexible as well. Additionally, it is light and may be affordable.

2. E-Paper's technology

Also known as Electronic Paper or Electronic ink Display, the E-Paper has both names. Nicholas K. Sheridon, working at Xerox's Palo Alto research facility, created the first E-Paper in 1974. The first electronic paper was created by Gyricon, and it is based on a thin flexible plastic sheet that rotates freely and is covered in a layer of small plastic beads that are each enclosed in oil. The polyethylene spheres that made up Gyricon ranged in size from 75 to 106 micrometres. Every sphere is a Janus particle, with a black sphere on one side that is negatively charged and a white sphere on the other. Front plane and backplane are two distinct sections of an E-Paper. E-Ink is used for the front plane while electronic circuits are used for the backplane [4].

|

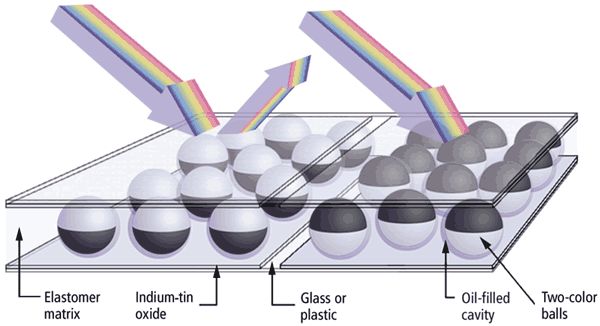

Figure 1. Gyricon Display of Electrophoretic Display. |

A front plane of electrophoresis contains tiny charged submicron particles floating in a dielectric fluid, which is contained in a cell or microcapsule that is smaller than a pixel. Fig. 1 shows the Gyricon Display of Electrophoretic Display. When a cell or capsule is subjected to an electric field, the ink particles will flow in the direction of the electrode that has the opposite charge. When electricity is delivered to a transparent electrode, the cell or capsule absorbs the ink's colour. By utilising particles with oppositely charged polarities, such as black and white, the contrast is increased.All the black particles will go to one side when current is applied, and all the white particles will move to the other. The capsule's colour will change if the field is switched [5].

|

Figure 2. Fabrication of E-paper at Xerox PARC. |

The oil-filled chambers of an elastomer are where the Gyricon display's spheres are imprisoned. They enter the reflecting (left) or light-absorbing (right) black states depending on whether they are placed with a positive or negative voltage. At Xerox PARC, prototypes have been created. Fig. 2 shows the Fabrication of E-paper at Xerox PARC [6].

3. Electrophoretic display

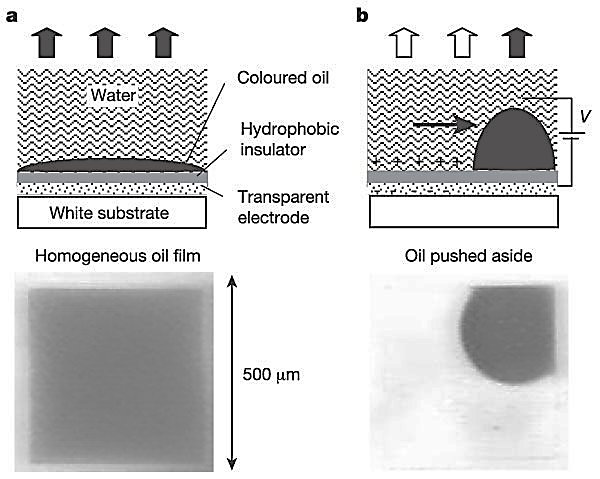

The electrostatic movement of particles related to scattering of light come in contact with a dyed colloidal suspension is the basis for all electrophoretic displays. The particles move electrostatically in the direction of the electrode on the viewer side when a positive voltage is supplied. It is possible to get a reflection that is close to Lambertian if white light-scattering particles are utilised. Fig. 3 is representing a variation of Electrowetting Display. With the application of negative voltage, the migration of particles towards the electrode that is to the viewer's side and blend in with the dye, leaving the viewer only with the dye's colour [7].

|

Figure 3. A variation of Electrowetting Display. |

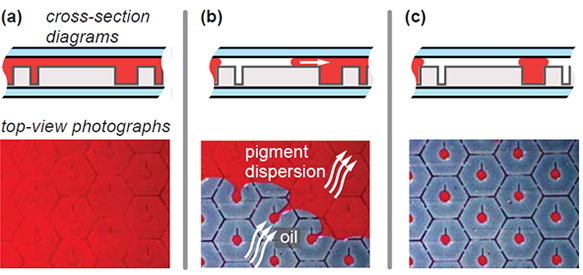

4. Electrofluidic displays

An alternative to electrowetting displays is electro fluidic technology. In a small reservoir, aqueous pigment dispersion is used in electro fluidic displays. The pigment is mostly hidden from view because the reservoir makes up between 5 and 10% of the visible pixel area. The pigment is dispersed as a film right below the viewing substrate after being electromechanically pulled out of the reservoir by voltage. Fig. 4 shows the variation of electro fluidic display. The display then acquires colour and brightness that are comparable to those of traditional pigments printed on paper. The white particles remain in place after migration takes place in either polarity and the voltage is withdrawn, resulting in the creation of a bistable memory device.

|

Figure 4. A variation of Electro fluidic display. |

5. Interferometric modulator (mirasol)

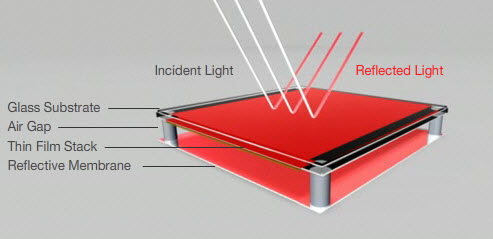

Figure 5 shown below representing the interferometric modulator for MIRASOL. Two major findings are-

1. Technology for electrical visual displays that uses light interference from reflected light to produce a variety of hues.

2. A tiny cavity that is electrically switched on and off by driver integrated circuits similar to those used to address liquid crystal displays serves as the color selector in the electrically switched light modulator (LCD).

|

Figure 5. Interferometric Modulator Display of MIRASOL. |

6. Advantages

• Readable like paper

• Visibility in sunlight and varying light conditions

• High resolution, contrast, and reflectivity

• 180 degree viewing angle

• highly adaptable

• Extremely Low Power Usage

• Long-term Images that are difficult to read when there is no power

• extra battery life

7. Applications

• Electronic Book

• Electronic Newspaper

• Mobile display

• Computer monitor

8. Additional perspective

A person can easily carry an E-paper in their pocket because it is integrated into a 15-20 centimeter long, 1 centimeter in diameter cylindrical tube. The E-paper will be firmly rolled inside the tube and can be unrolled as a flat sheet for reading and then stored once more with the push of a button. A basic user interface will be used to download data from an internal memory chip or from a network of cell phone or from a satellite. The essential part is the document reader. It can be utilized for everything on the planet, including magazines, email, books, the internet, technical manuals, newspapers, and more.

9. Conclusion

Paper is still the most common document medium in use today because of its dependability, palpability, usability, mobility, flexibility, and compatibility, all of which have made it difficult to replace. The concept of a paperless office is further away than when it was first envisioned, despite the widespread use of computers and online documents. The need for new document management systems is becoming more and more apparent as paper and documents flow at a faster rate than ever. We should reevaluate the claim that all paper documents will eventually be replaced by electronic documents because new technologies are often mistakenly seen as complete replacements for older ones. As a result, we anticipate that paper and E-paper will coexist in the future.