1. Introduction

In retrospect, the engines have a long history which can be dated back to the 150BC, at that time the first aeolipile may already appeared, and it did not be used on any machine. However, one still thinks that Dr. Hans von Ohain and Sir Frank Whittle are the father of jet engine, they began working together in April 1936. Miraculously, they did not know each other and their work. The gas or liquid will through the backward ejection with high-speed to give plane a thrust called jet propulsion and jet fuel is responded for machine’s power during any engines and air travel [1].

As just mentioned, in 150BC the aeolipile did not be used on any invention, actually, the first it be used on a firework is by a Chinese artist in 13th century. In 1633, Lagari Hasan Çelebi of the Ottoman Empire employed a rocket with a conical design, which operated on the principle of jet propulsion, to ascend into the sky. He then utilized a set of wings to navigate the rocket back to the ground for a safe landing. However, due to the inefficiency of rockets at low-speed for regular flight operations, this especially application of jet propulsion was more of a singular demonstration than a practical approach for sustained aviation [2]. Because the ramjet also needs an extra booster, and it for single use too. Nonetheless, unlike Lagari’s rocket, the ramjet works under the high speed. That is the Early Jet Propulsion Concepts. Regarding advancements in aircraft engine technology, on February 16, 2023, the CA42, China's inaugural general-purpose aircraft, successfully conducted its test flight powered by the domestically developed AEC2.0L aero engine [3]. Actually, AEC2.0L aero engine is a piston engine independently developed and produced by Wuhu Diamond Aero Engine Co., Ltd., which has the advantages of high reliability, good economy and strong power. The engine has addressed numerous critical software and hardware technological challenges that were previously impeding progress [4]. Nowadays, there some new energy resources be used on the planes. In December 2023, the EcoPulse, a hybrid prototype jointly developed by Daher, Safran and Airbus, successfully made its maiden flight. The prototype, powered by batteries and a turbine generator, completed its first hybrid flight [5]. Airbus is contributing battery technology and aerodynamic modelling to this project, which aims to leverage the benefits of distributed propulsion to improve aircraft performance [6]. These two are the latest engines on the jet. In general, this thesis wants to tell people how different types of aircraft engines differ, and their advantages or disadvantages brought by these differences, therefore the multitude can further understand these engines. Sec. 2 and Sec. 3 begin with an introduction to these different types of engines. The fourth part will discuss some of the newest engine installations available. The strengths and weaknesses of engines and their future trends will be discussed in Sec. 5. Eventually, a conclude remark is given in Sec. 6.

2. Description of engines

For now, jet engines can be divided into five main types: ramjet engine, turbofan engine, turbojet engine, turboprop engine, and turboshaft engine. Ramjet is the most special one among these five,it cannot take off from the ground itself without compressor. It needs an extra booster; therefore, the common application of ramjets is in missiles and other military weapons systems. Ramjets are capable of producing high levels of thrust, making them suitable for use in high-speed missiles that need to travel at hypersonic speeds to reach their targets quickly [7]. In the case of a ramjet engine, the mass flow rate at the exhaust is nearly identical to that of the incoming airflow, as the addition of fuel to the flow is minimal [8]. That is the parameter of ramjet. At present, most airliner are equipped with turbofan engines. By the way, turbofan engine is evolved from turbojet engine. There is a new concept be introduced by turbofan called bypass ratio. It plays a important role in turbofan’s parameter. Early turbofan engines and modern fighter jets have low bypass ratios. For example, the world first turbofan engine, the Rolls-Royce Conway, has a bypass ratio of only 0.3. Most modern civil aircraft engines usually have a bypass ratio of more than 5. Turbofan engines with high bypass ratios consume less fuel, but have thrust comparable to turbojets, and are much quieter when running.

Concentrating on the most important engine, turbojet engines are suitable for a wide range of flight applications, from low-altitude subsonic aircraft to high-altitude supersonic aircraft. The legendary MiG-25 high-altitude supersonic fighter of the former Soviet Union uses the turbojet engine of the Lyulka Design Bureau as its power, and once set a fighter speed record of Mach 3.3 and a ceiling record of 37,250 meters. About the speed of turbojet engine. The turbojet engine, as exemplified by the cutaway illustration provided, is commonly employed in a variety of aircraft, especially those intended for high-speed flight, including supersonic applications. However, the turbojet's propulsive efficiency is notably diminished at lower speeds, which restricts its applicability primarily to high-speed aircraft. Extended by the turbofan engine, the turboprop engine and turboshaft engine came out. The structure of turboprop engine is very similar to the turbofan engine, so it has great bypass ratio too. Due to the great weight to the prop, it speed cannot reach the speed of the turbine, and prop needs a gearbox to lower the turbine. While turboprops are often utilized in smaller commuter aircraft, they also find application in certain general aviation planes and military training aircraft [9]. The last one turboshaft engine, it has similar structure with turbojet engine, however turboshaft has advantage on weight ratio comparing with turbojet engine. Frequently, the selection of turboshaft engines for helicopters is queried. The rationale is straightforward: these lightweight, compact gas turbine engines produce a disproportionately higher power output compared to piston engines, which enables helicopters to achieve vertical lift [10].

3. Principle of different engines

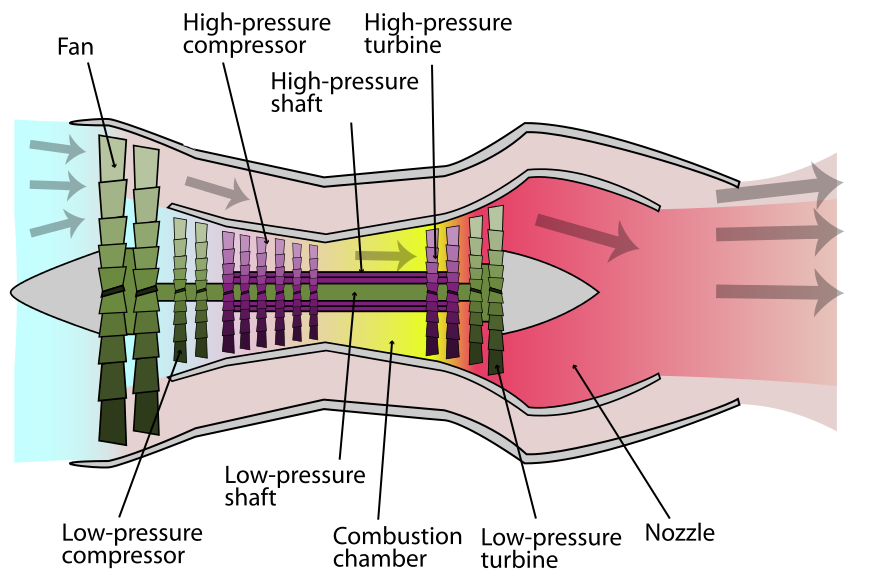

This part will explain the principles of two most important engine, turbofan engine and turbojet engine. On account of the principles of turboprop engine and turboshaft engine are very parallel to those two. Hence, one can ignore these two temporarily. Firstly, turbofan engine uses the thrust to move airliner. When the air is absorbed into engine, the air will be divided to two different pass. About the internal design for turbofan, it has two compressors in there. The function of the low-pressure compressor is to elevate the air pressure, while the high-pressure compressor further increases the pressure and concurrently raises the air temperature. Air initially enters the low-pressure compressor, followed by the high-pressure compressor. Combustion is initiated in the combustion chamber when the fuel encounters the heated air. Then the thrust is produced by the mixture generates high-speed gases in nozzle. With the great bypass ratio, the air-flowing can be faster. Fig. 1 is an internal structure diagram for turbofan engine.

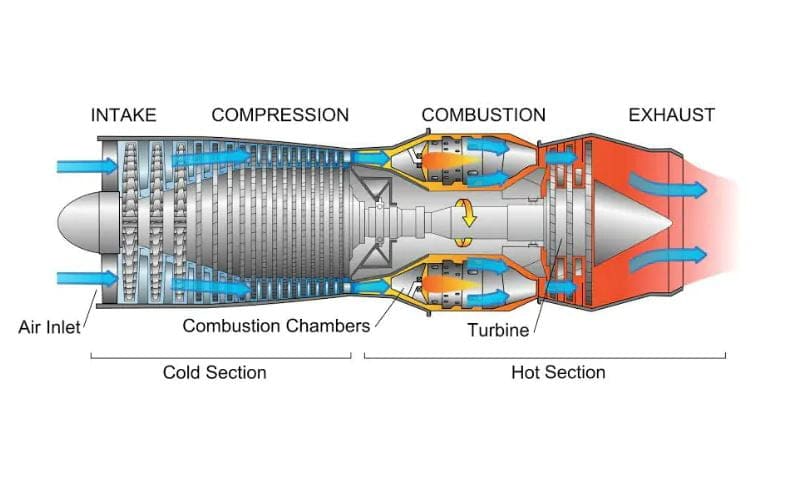

Compared with turbofan engine, the air absorbed into turbojet engine will flow into the diffuser first. Then as the same progress with turbofan engine, air will secondly come into compressor and will compress itself pressure. Pump in the combustion chamber has a little hole that provides the fuel. But the fuel in turbojet is few. Finally, the mixture gas flows into the turbine and generates the kinetic energy, the waste gas will release from the nozzle to produce the thrust. Fig. 2 shows a turbojet engine’s internal structure [12].

Figure 1. Diagram for turbofan engine [11].

Figure 2. Diagram for turbojet engine [12].

4. State-of-art facilities

This part will continue discuss the latest technology used on turbofan engine, turbojet engine and the true parameter of these two. Turbofan engine as the main engine of the commercial airplanes, it’s one of the most fuel-efficient engines available. To improve engine efficiency without affecting other factors, an alternative approach could involve the implementation of the Adaptive Cycle Engine (ACE) principle [12]. Most of time, turbofan engine works in subsonic speed environment, the turbojet engine used on military airplanes flies in supersonic speed situation. Fortunately, ACE is appropriate for both two engines with two thermodynamic cycles. Additionally, the ACE model's variable bypass ratio confers it with several benefits, particularly in terms of enhanced overall efficiency, extended flight range, and reduced specific fuel consumption [13]. As the results, the ways to improve engines efficiency with ACE are changing the low bypass ratio that is a common failing to turbofan engine. By using specific fuel consumption, specific thrust, power and efficiency parameters. The alternative approach examined various methodologies for assessing design parameters, including the specific thrust (ST) and specific fuel consumption (SFC) values of the ACE model, specifically in the context of dual-bypass and single-bypass configurations, as per Balli's 2017 research [14]. Furthermore, temperature of air is also a essential factor. Therefore, the main method of analysis would be done by using computer software called GasTurb. The software in question is designed to facilitate the simulation of various gas turbine performance calculations and to optimize their operational parameters [15].

At present, the largest turbofan engine is the GE90, which is utilized in the Boeing 777 aircraft. Manufactured by GE Aviation, the GE90 engine series is recognized for its high bypass ratio and offers a thrust range that spans from 74,000 to 115,000 pounds-force (329 to 512 kilonewtons) [16]. The initial versions of the GE90 engine were capable of generating thrust levels ranging from 74,000 to 94,000 pounds [17]. According to research, the purposes of developing the turbojet engine are more like to link with environmental, economy and efficient. NASA will co-operate with GE Aerospace to design a super efficient airplane. Theoretically speaking, it can cut down 10 percent fuel using by comparing with other engines. The thrust on turbojet engine is generated by compressing the air and combustion. NASA wants to do something about shrinking the core to improve the efficiency of combustion and reduce the carbon emission. So greener and more efficient fuels and materials that are more resistant to high temperatures are becoming particularly important. New energy fuel look like the best option, solid oxide fuel cell (ITB-SOFC engine) extremely increases the engine efficiency which it energy conservation rate can achieve 60%. Analysis indicates that the ITB-SOFC engine outperforms the turbojet engine in terms of thermal efficiency and specific thrust, with potential increases of 2.94% and 23.87% respectively for these parameters [18]. The solid oxide fuel cell (SOFC), considered a promising contender among fuel cells, boasts high efficiency and has the capability to directly utilize hydrocarbon-based fuel [19]. Since the SOFC adopts an all-solid-state ceramic structure, by using this cell, the cost of the fuel can be saving too. About the effect of environment, it can effectively avoid the corrosion and leakage problems. Because the reactants of SOFC only have CO2 and O2, the condensation of water vapor can trap the CO2, therefore, the amount of emission of CO2 is almost 0. Material relating to core resistance to high temperature, at present the most popular material on market is Ceramics Matrix Composite (CMC). Structural ceramics offer numerous benefits, including a minimal creep rate, exceptional hardness, robust strength, and a high level of resistance to thermal stress, erosion, and corrosive environments [20]. Consequently, ceramics and ceramic-matrix composites featuring surface microstructures find broad applications across diverse sectors, such as photoelectric imaging, aerospace technology, optical communication, and fuel cell technology, among others [21]. These characteristics just meet the requirements for core high temperature resistance. Meanwhile, compare with some alloys, it will save more cost.

5. Comparison, limitations and prospects

The turbojet engines compare with the turbofan engines are more suitable for the military airplanes and some supersonic planes and most of airliners usually use the turbofan engines, because when they are flying at lower than 724km/h their efficiency will lower than turboprop engine, however when they are flying at more than 563km/h, their efficiency will rise. Thus, pure turbojet engines are best suited for higher flight speeds. But the limitation on turbojet engine is obvious too. Their fuel consumption is higher than turbofan engine or others. And this point makes them relatively low efficient, also increases the cost. Otherwise, noise be produced by turbojet engine which can contribute noise pollution. Now major companies are still devoting oneself to promote turbofan engine technology. For example, the GE Aerospace and NASA to start designing more sustainable turbojet engine core.

The beauty of a turbofan engine is that it increases the pre-turbo temperature without increasing the exhaust speed (by increasing the exhaust flow at lower speeds, reducing the average exhaust speed). Knots of turbofan engines. The turbofan engines have external duct; therefore, it can make more air to flow around the external duct to reduce the exhaust speed but does not decrease the thrust. It can make the engine much quieter than the turbojet engine too. And the efficiency of these two engines is similar. The disadvantages of turbofan engines are that the diameter of extra fan is big, its windward area is large, the resistance is also large, another is the design is difficult. The current market outlook of turbofan engines is still positively. The sales of turbofan engines are projected to experience a compound annual growth rate (CAGR) of 17.2% between 2022 and 2032, culminating in a market value of US$ 5.1 Billion by the close of 2032 [22]. Since the most popular mode of travel is still aircraft, the demand from airline and military for turbofan engines evolution is still growing.

6. Conclusion

To sum up, this study provides a basic overview of the different engines and some difference between them, in-depth analysis of the two most important engines, their structure, strengths and weaknesses, and the technological updates they are facing as well as their implementation parameter. According to the research findings, the update of the engine and improvement of technology is still a popular task in the market especially some hybrid systems, and most research and development institution will be environmental protection as a very important consideration how to reduce the carbon emission or energy-saving fuel. There is a still a long way to go in the future engine development, and it is looking forward to some new ideas on engines design.