1. Introduction

1.1. Bridges in China

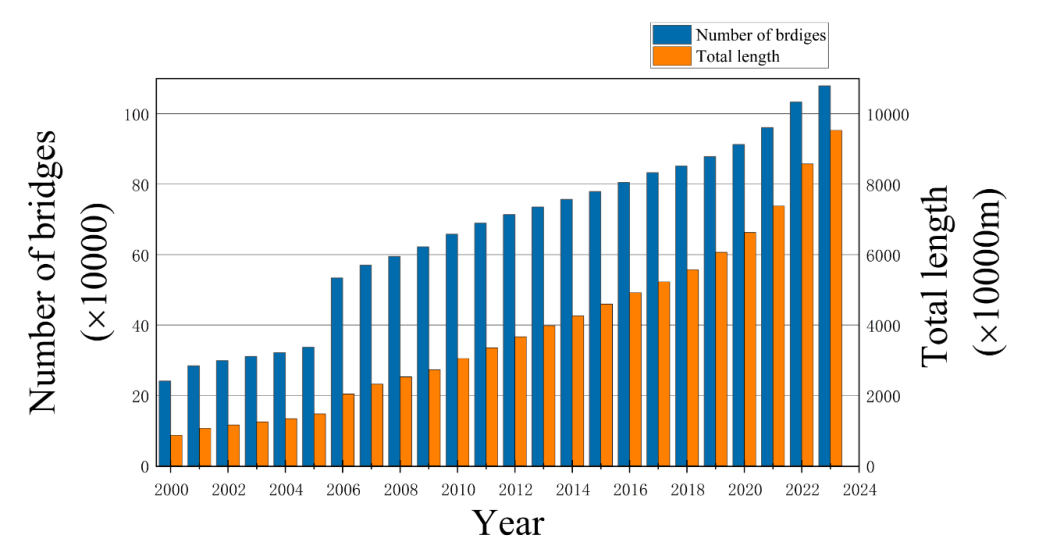

From 2000 to 2023, China has witnessed a remarkable expansion in its bridge infrastructure. As shown in Figure 1, with the total number of bridges increasing from 240,600 to 1,079,300, and the total length of bridges soaring from 8.655 million meters to 95.2882 million meters. According to statistic, within the total of 1,079,300 highway bridges, including 10,239 super bridges, 177,700 large bridges, 891,400 medium and small bridges [1].

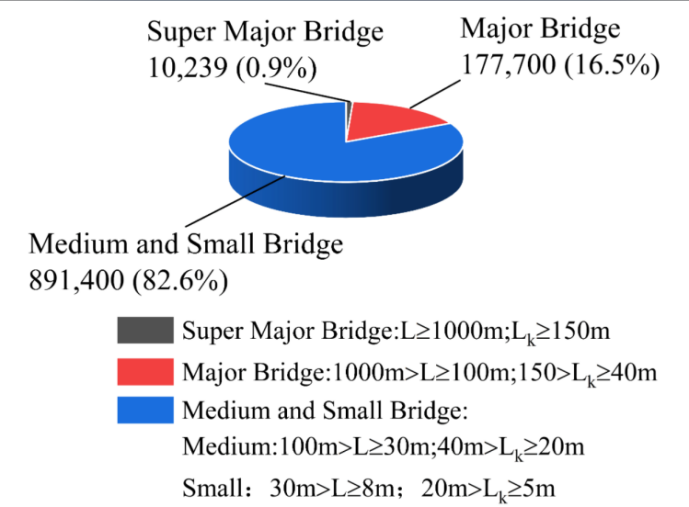

China has embarked on a brilliant era in long-span bridge construction, As shown in Figure 2, the Super Major Bridge and Major Bridge collectively constitute 17.4% of the total. And achieving breakthroughs in design theories, structural systems, materials, and construction techniques. Multiple world-class river and sea-crossing bridges have been constructed, enriching global bridge engineering expertise and fostering regional economic growth, connectivity, and national strength. Our innovations have set new standards for global bridge technology.

1.2. Current situation and existing problems

Transportation infrastructure, particularly highway bridges, is crucial for economic development due to their substantial cost and significant impact on public safety. Various factors contribute to the accelerated deterioration of existing bridge structures, including the aging of bridges, increased traffic volume and excessive truck weights, harsh environmental conditions, and suboptimal maintenance decision-making.

To maintain aging bridges in severe condition following detailed inspections, it is imperative to adopt new technologies and methods to enhance load-carrying capacity and ensure structural safety. Typically, the total expense of inspection, assessment, and maintenance constitutes only about 10-20% of the cost of rebuilding. During maintenance, traffic closures are generally unnecessary except for short-term detours for heavy-duty vehicles, yielding clear economic benefits. Therefore, establishing a durability assessment system for old bridges and formulating fundamental principles for their strengthening is an urgent problem that requires resolution. The "Research and General Applications of the Inspection, Assessment, and Strengthening (I.A.&S.) of Old Highway Bridges" project [2,3], certified by the Ministry of Communications, has been systematically, standardized, and specialized in China.

|

Figure 1. The increase of the number of highway bridges from 2000 to 2023 |

|

Figure 2. Percentage of all highway bridges in 2023 |

2. Bridge inspection and maintenance

A robust bridge condition assessment and inspection system can verify bridge design and construction quality, evaluate service levels, identify damage location and extent, and assess the safety and durability of bridges in severe conditions. This ensures traffic safety, extends the service life of bridges, reduces maintenance costs, and enhances bridge performance. Inspections include frequent, periodic, and special inspections, depending on the objectives. Three primary methods are used: non-destructive testing (NDT), semi-destructive testing, and loading tests [4]. NDT methods assess concrete strength, internal structural damage, and damage location. Loading tests evaluate structural performance and load-carrying capacity. Loading tests require comprehensive on-site experiments and theoretical knowledge. Combining theoretical calculations with real bridge inspections is essential for obtaining accurate assessment results.

The maintenance work of bridges is equally crucial and should be conducted in accordance with the following steps:

• After being assessed by the “Load carrying capacity assessment methods of old highway bridges”, the bridges which no longer guarantee the safety and serviceability should be retrofitted. The content and scope of maintenance designs should be made according to the assessment results and requirements of their clients.

• Bridges identified as unsafe or unserviceable following assessment using the "Load carrying capacity assessment methods of old highway bridges" should undergo retrofitting. Maintenance designs must be tailored based on assessment outcomes and client specifications.

• Restoration of bridges to their original design lifespan is essential.

• Close integration of maintenance designs and construction methods is crucial to ensure effective connection between old and new structures.

• For major load-bearing elements of larger bridges requiring reinforcement, at least two maintenance methods should be proposed. Economic feasibility assessments should guide method selection.

• Preservation of original structures and valuable components should be prioritized to minimize unnecessary removal or replacement.

• Verification of load carrying capacity is imperative in the maintenance design phase.

3. Maintenance strategies of superstructures

Among the reinforced bridges, the superstructure has been strengthened more frequent than the foundation, so the study and discussion focused on superstructures.

3.1. Strengthening with the reinforced layer

To strengthen bridge decks, enhancing load capacity, stiffness, and compressive zones, cast-in-place reinforced concrete slabs are attached to the existing deck. This addresses load capacity, stiffness, and joint defects, especially suitable for small-to-medium spans due to reinforcement layer thickness constraints. Key to quality assurance: adherence to material specs, strict manufacturer guidelines for adhesives, surface prep preserving concrete strength without damaging prestressing, and avoiding under-reinforcement or voids. These measures ensure structural integrity and performance.

3.2. Strengthening with external prestressing

This method can greatly restore the load-bearing capacity of old bridges, small damages to original structures. The navigation clearance is not influenced, and elevation of bridge deck not increased. For the prestressing strand are arranged outside girders and slabs, the corrosion proofing treatment should be employed in the construction. Strengthening with external prestressing can be applied to the beam, which has large deflection, low moment-resisting capacity or wide cracks in the tensile zone.

3.3. Strengthening with Carbon Fiber Reinforced Polymers (CFRP)

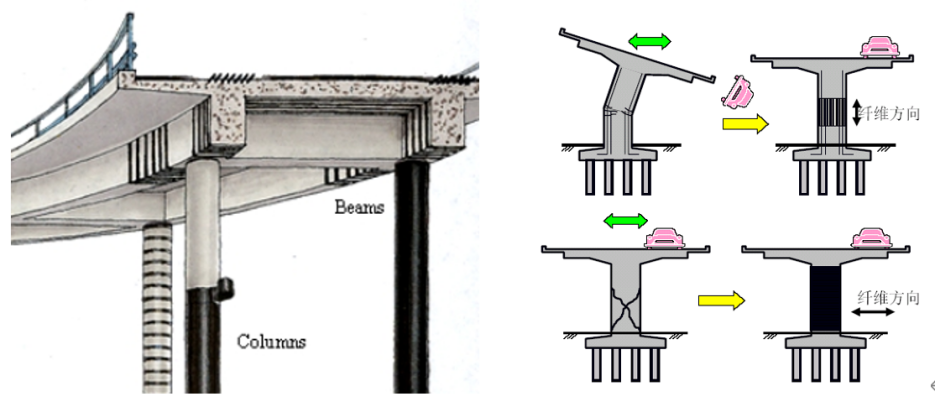

CFRP has some better performances in comparison with other materials, such as linear elastic behaviour to failure and no yielding, higher ultimate strength, lower strain at failure and higher modulus of elastic. For the bending strengthening of concrete bridges, the ultimate improvement of structural bearing capacity is 40%, specially the limitation should be considered when its anchorage quality can not be guaranteed. The load-carrying capacity of reinforced structures still depends on the original structure. Strengthening with CFRP can not obviously improve the stiffness of the moment-resisting members, but effectively control the development of cracks. This strategy can be adopted comprehensively in the maintenance work of structures [5], as shown in Figure 3.

Figure 3. Application of CFRP systems |

The strength of domestic PAN-CFRP is between 2 000 and 2 500 MPa, and elastic modulus is about 210 GPa, but the above single performance can not meet the requirement for diversification of CFRP. Therefore, developing the domestic CFRP market is a key issue. A series of experimental research should be carried out to test and verify the fatigue strength, durability, ductility and other technical properties. Domestic corresponding codes and specifications should be made to improve the application of strengthening with CFRP in China.

The arrangement of carbon fibers is uniform after being made into sheets, which ensure the entities subject to forces uniformly. Generally, saturating resin used to be employed in the Carbon Fiber Sheet to ensure the reliable connection between CFRP and concrete structures. Current three-step bonding method [5] is scientific and able to guarantee the quality.

3.4. Steel-sticking technologies

When bridge girders suffer from low load capacity, rusted rebars, and lateral cracks, reinforcing with steel plates bonded via adhesives and anchor bolts can strengthen the bridge. This technique works well in bending, shearing, and tensioning, withstanding temps from -20°C to 60°C, RH under 70%, and minimal chemical corrosion. For under-reinforced beams, increased loads cause original rebars and then steel plates to yield, followed by concrete crushing. In bending, strong adhesion enables steel plates and concrete to work in unison until cracks form between them, leading to concrete failure and inability to bear loads, as depicted in Figure 4.

|

Figure 4. Strengthening with the Steel-sticking technologies |

3.5. Changing the work system of old bridges

The working system and bridge condition are changed by adding additional members to reduce stress on bearing components and enhance bridge performance and load-carrying capacity involves several methods. These include converting from simple-to-continuous support, modifying multi-span simply supported beams to continuous systems, adding auxiliary piers, employing eight-type bracings for reinforcement, converting beam bridges to composite beam-arch systems, transforming small bridges into culverts, and strengthening with stay cables. The usual methods include mainly as follows: the simple-to-continuous supporting method, changing the multi-span simply supported beams to simply supported systems with the continuous deck, adding auxiliary piers, strengthening with eight-type bracings, changing beam bridges to the composite beam-arch system, transforming small bridges to culverts, and strengthening with the stay cable.

4. Strengthening technologies of the foundation

4.1. Expanding the infrastructure of bridges

The size of foundation is enlarged to improve its load-carrying capacity. It’s applicable to strengthening the bridges, which have the low bearing capacity or small embedment depth. If the bearing capacity of the foundation is not enough for the enlarged bases, some displacement piles can be driven into the subsoil in advance. The number of driven piers is determined according to the deformation of foundations.

4.2. High-pressure jet grouting

Strengthening with high-pressure jet grouting is that, inserting grouting tubes with spray nozzles into the ground to design depth by drillers, rotating and ascending with certain speed, at the same time, slurries and water jetted as a high-pressure flow from the nozzle, to impact and destroy the soil, forming the disperse granular, some of which are taken out by slurries and water and the others mixed with slurries, as mixtures consolidating, a solid with certain strength and impermeability is formed. This is one of the most effective methods of strengthening foundations. During the grouting, speeds of rotating and ascending can be adjusted, the pressure and flow rate of slurries can be changed to form the consolidations of diverse shapes, and guarantee the strength and durability of consolidations. The construction facilities are simple, management convenient, construction safe, and vibrations of devices weak. This strengthening method has low costs and little noise, which will not affect the surrounding normal living of citizens.

4.3. Adding pile foundation

When foundation load capacity is insufficient, driven or cast-in-place piles are added, and platforms enlarged to integrate with these piles. This transfers pier/abutment pressure to new pile bases, enhancing load-carrying capacity and stability. Advantages include no need for underwater work, noticeable maintenance effects. However, installing pile drivers and excavating bridge decks impacts traffic and waterways. This method is also used to strengthen old bridges' substructures, addressing under-clearance issues. Precast piles can be inserted silently using manual jacks, providing platforms for piers to integrate new and old piles. This reliable approach improves bearing capacity and stability, requiring partial traffic closures during maintenance.

4.4. Adjusting the horizontal displacement of springing

The horizontal displacement of abutments increases positive moments in the crown zone, leading to radial cracks. A crack width of less than 0.2 mm is permissible. However, if the cracks are too wide and dense, the damage becomes serious and may diminish the strength of the main arches. Incremental launching technologies can be applied to eliminate damage caused by abutment displacements and adjust the internal forces of the arch ribs. The original cracks can be diminished or eliminated, the displacement of the crown can be recovered, and the bending stiffness can be improved after strengthening with this method. This method is applicable for strengthening RC rigid frame arch bridges, trussed arch bridges, and two-way curved arch bridges, whose abutments are likely to experience displacement. This technology is also an effective measure to adjust arch stress.

5. Conclusions

China has now become the world's leading bridge and highway nation. The demand for funding has gradually shifted from constructing new bridge structures to the repair, rehabilitation, and replacement of existing ones. Bridge assessment is crucial as it provides sufficient information for subsequent maintenance work [6-9]. This paper introduces some common methods and technologies for bridge maintenance, and the conclusions are as follows:

• In the superstructure, strengthening with external prestressing can significantly improve the performance of structural members. External strengthening with CFRP materials has a wide range of applications. These methods are cost-effective compared to traditional methods and can be conducted during the service stage.

• From both technological and economic perspectives, it is rational to strengthen compressive members with steel-encased structures.

• From the foundation of bridge, high-pressure jet grouting offers reliable quality, low maintenance costs, convenient construction, and significant effects, making it one of the most effective methods for strengthening bridge substructures.