1. Introduction

The advent of sensor technology represents a pivotal milestone in humanity’s quest to explore and understand the oceanic depths. The inception of modern ocean sensor technology, coupled with its continuous evolution, has established a robust foundation for augmented ocean observation capabilities[1]. Moreover, the integration of advanced sensor technologies into robotic platforms has opened new vistas for ocean exploration. These robotic platforms, equipped with state-of-the-art sensors, can operate in extreme conditions and reach areas of the ocean which are previously inaccessible for human beings, thereby expanding our observational capacity and enhancing our understanding of the marine environment. Despite sensor technological has greatly stridden , the domain of conservation for instrumentation—especially sensors of considerable value and importance on robotic platforms—remains relatively underexplored.

In recent years, the field of sensor technology has witnessed multifaceted and profound advancements, encompassing enhancements in sensor accuracy, ubiquity, and specialization, among other aspects. Yadav et al. created solid-state proton conducting electrolyte-based hydrogen isotope sensors which have good physical and chemical sustainability in liquid Pb-Li at higher temperatures, making sensors breakthroughs in specialized segments [2]. Pawlenka et al. made a development of custom captative sensors which used limited and available resources but achieved high performance, improving the versatility of sensors [3]. Xu et al. presented a compact non-dispersive infrared gas sensor which are available in high-moisture and low temperature environments [4]. However, there are few literatures of research concerning the protection mechanisms for sensors equipped on underwater robots. Nonetheless, the discourse surrounding the protection of pivotal equipment against external perturbations for subaquatic robots signifies a domain ripe for further academic inquiry.

This literature is devoted to the conceptualization and development of a biomimetic robot, inspired by the self-preservatory mechanisms exhibited by tubeworms. Initially, the study will undertake a comprehensive examination of the tubeworm’s physiological architecture, elucidating the function of its multilayered protective sheaths. Subsequently, the investigation will delineate the variables contributing to the tubeworm’s rapid contraction in response to external stimuli, employing methodologies such as empirical experimentation and tabular analysis. During the robot’s design phase, SolidWorks will be utilized to construct a detailed model, whereas ANSYS Parametric Design Language (APDL) will be employed to assess the rigidity and durability of critical components.

The objective of this scholarly endeavor is to investigate the possibility of fan worm biomimetic robotic systems, drawing inspiration from the innate defensive strategies exhibited by the tubeworm species. This research will commence with an analysis of the tubeworm’s physiological structure, with a particular focus on elucidating the operational dynamics of its stratified protective integument and special physiology structure for reduced resistance. Subsequently, through a combination of experimental methodologies and analytical techniques, the study aims to delineate the pivotal variables that precipitate the tubeworm’s rapid retraction in the face of external provocations.

During the robotic design phase, comprehensive computational models will be formulated utilizing the SolidWorks platform, while the structural integrity and resilience of pivotal components will be rigorously assessed via the ANSYS Parametric Design Language (APDL). The overarching ambition of this inquiry is to engineer more efficacious sensor safeguard mechanisms for subaquatic robotic entities, thereby augmenting their operational stability and dependability within the intricate milieu of marine environments. The biomimetic tubeworm-inspired robotic prototype, which replicates the natural attributes of its biological counterpart, has demonstrated commendable reliability and sensor protection capabilities, significantly enhancing the efficacy of marine resource exploration and exploitation endeavors. This, in turn, has facilitated advancements in marine scientific research, catalyzed deep-sea archaeological and exploratory initiatives, bolstered national defense and security measures, and expanded the scope of educational resources.

In the domain of marine resource exploration and exploitation, the robotic system is engineered to function with reliability in extreme subaquatic conditions, with precision to execute prolonged resource exploration assignments. Moreover, the robotic system is designed to enhances the accuracy of resource localization and the safety protocols of developmental operations. The high-precision sensor safeguard mechanism ensures the reliability and precision of data acquisition, thereby providing robust technical underpinning for the sustainable utilization of marine resources.

For the advancement of marine scientific research, the Bionic Tubeworm Robot serves as an efficacious research platform capable of penetrating oceanic depths for extended periods, thereby enabling long-term surveillance of marine ecosystems, biodiversity, and environmental fluctuations. The real-time data procured contributes to a more nuanced comprehension of the marine environment’s complexity and its dynamic transformations. In the context of deep-sea archaeology and exploration, the robot’s precision in positioning and operational capabilities in deep-sea settings, along with its adept sensor protection mechanism, are instrumental in the detection and study of submerged artifacts and shipwrecks, thereby playing a pivotal role in the conservation of underwater cultural heritage.

Within the realm of national defense, the Bionic Tubeworm Robot’s stealth and adaptability render it an ideal candidate for underwater surveillance and reconnaissance missions, thereby fortifying national defense security and the execution of maritime strategies. Furthermore, its application in the educational sector serves as a potent catalyst for fostering interest in marine sciences and engineering among students, promoting interdisciplinary educational approaches, and nurturing the scientific literacy and innovative capabilities of future generations.

In conclusion, the development and application of the Bionic Tubeworm Robot represent its technical potential and demonstrates a range of applications in different areas. It has its significant in propelling the progress and development of related scientific and technological industries.

2. Physiological Structure of Tubeworms and the Analysis of the Variables Leading to Their Retraction

2.1. Physiological Structure of Tubeworms

Tubeworms, sessile polychaetas, reside within secreted tubular encasements as adults, projecting fan-shaped tentacular structures from the tubular structure for respiratory and filter-feeding purposes. To deal with predatorial threats to the tentacular fan, these organisms have developed ocular mechanisms at the tentacle extremities capable of detecting intrusive entities in the aquatic environment, eliciting a swift withdrawal reflex. The tubular encasements of these worms predominantly comprise acidic mucopolysaccharide-protein complexes, secreted by the worms themselves. Furthermore, the external layer of the tube incorporates environmental minerals and shell fragments, providing substantial protection.

The tubular morphology of the tubeworm is predominantly composed of acidic mucopolysaccharides and proteinaceous complexes, which are synthesized and secreted by the tubeworm itself. The exterior surface of this tubular structure is often encrusted with minerals and detritus, such as shell fragments, that are derived from the surrounding environment. This natural accretion serves to augment the tubeworm’s inherent defensive capabilities, offering an additional layer of protection against potential predation and environmental hazards. Additionally, the interior tube wall’s unique architecture offers stability against the frequent contractions of tubeworm. The body of tubeworm features numerous transverse folds, segmenting it into multiple sections, each equipped with hooks that are oriented contrary to the worm’s withdrawal direction. These hooks facilitate unidirectional immobilization of the worm’s body, independent of the external wall [5].

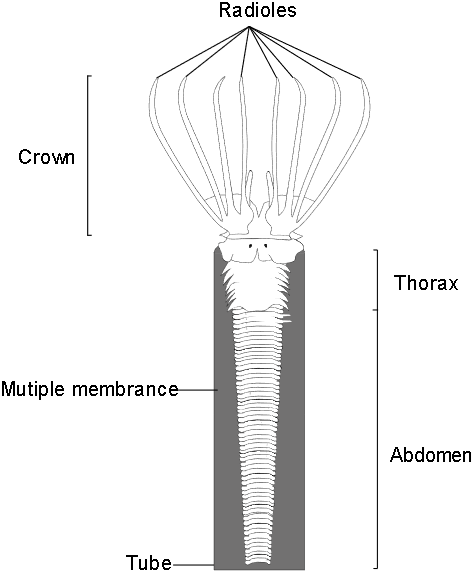

Experimental observations reveal that the tubeworm’s membrane sheath is composed of multiple layers, with older sheaths exhibiting a higher layer count than newer ones. Significantly, the internal surface of the tubeworm’s membrane is characterized by transversely arranged slits. Notably, the spatial distribution of these slits mirrors that of the hooks on the worm’s body segments, with respect to geometric spacing, as well as length and width dimensions. This unique structural can be demonstrated in Figure 1 [6].

Figure 1. The Structure of Tubeworms

2.2. Variables Contributing to the Retraction of Tubeworms

The accelerated retrieval mechanism in tubeworms can be attributed to several contributing factors. Primarily, it is contingent upon the synchronized contraction of the longitudinal and transverse musculature within the tubeworm’s structure. Examination of transverse sections of tubeworm musculature reveals that the longitudinally contracting muscles occupy a substantial portion of the total cross-sectional area, a proportion significantly larger than that observed in other annelid species. Secondarily, the phenomenon involves the flattening of the pinnae situated on the radial tentacles of the tubeworm. During rapid motion, entities presenting a higher resistance are more susceptible to encountering increased resistance and, consequently, are at a heightened risk of sustaining damage. This principle is applicable to the tubeworm tentacles as well. Additionally, the swift retraction of tubeworms is associated with the flattening of the wedge-shaped ridges formed by the body segments adjacent to their abdomen [8].

3. Modeling of the Tubeworm-Based Bionic Underwater Robot

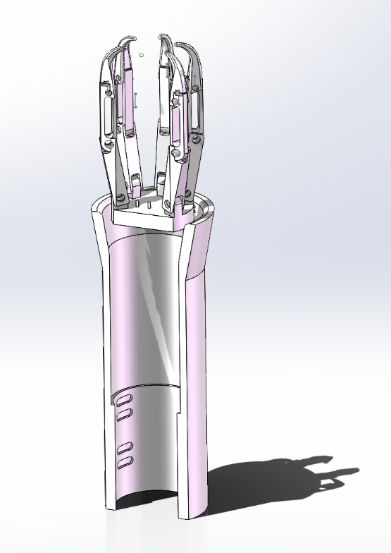

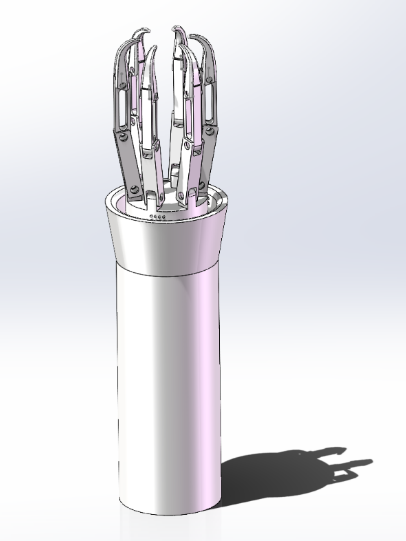

In the process of developing the experimental model of the bionic robot, this study utilized SolidWorks software for construction. The design of the robot was decomposed into key components, which were then meticulously modeled individually, with a focus on reflecting the physiological structure and functional characteristics of the tubeworm. Subsequently, these individually modeled parts were assembled according to design requirements and functional needs to form a complete robot model. Throughout the assembly process, attention was paid to ensuring the correct fit between parts and the stability of the overall structure, aiming to simulate the original physiological characteristics of the tubeworm as realistically as possible. This approach not only mimicked the tubeworm structurally but also functionally approached its natural behavior closely, particularly the rapid retraction, which will serve as a reliable basis for future bionics research and application development. Figures 2 and 3 depict the SolidWorks schematic and sectional view of the bionic robot, respectively.

Figure 2. Schematic diagram of the tubeworm bionic robot

Figure 3. Cross-section of tubeworm bionic robot

The bionic robot comprises the shell, bionic tentacle, base, retraction mechanism, fixation mechanism, and control system, with the modeling focusing on the shell, bionic tentacle, and base. The bionic tentacle opens outward when the base extends and is ring-shaped to protect sensors mounted on either the base or tentacle. The base connects to the retracting mechanism and bionic tentacles for power transfer, featuring tiny protrusions that fit into grooves on the shell.

4. Simulation analysis of key components of the bionic underwater robot model

In this study, ANSYS software is used to simulate and analyze the key components of the model. The main focus of the simulation includes stress-strain analysis, modal analysis and harmonic response analysis.

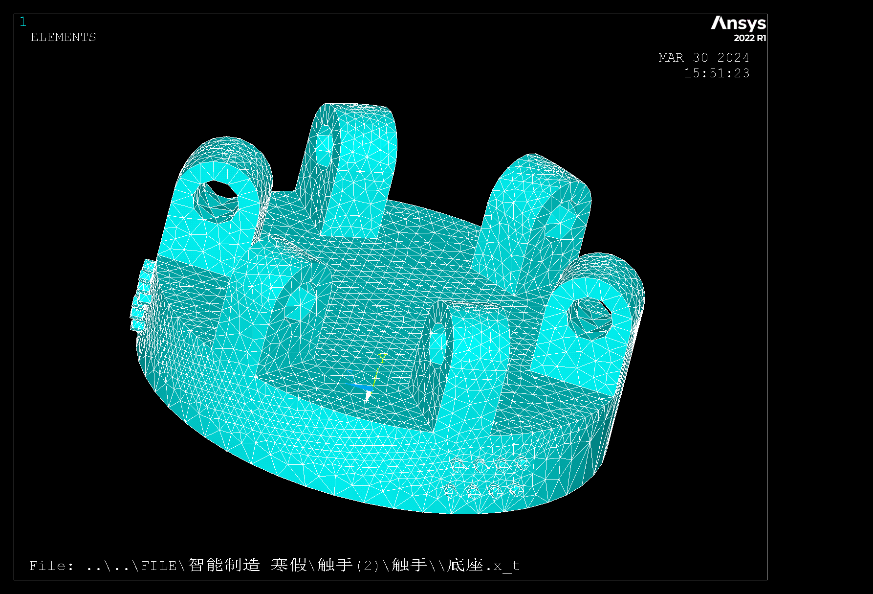

4.1. Static analysis

The key part selected for stress analysis is the connection part in the middle of the tentacle part of the bionic tube worm, which has more obvious stress concentration and is highly representative. The model built in Solidwork is imported into ANSYS. The structural is selected as the analysis type, and the Solid 3D is added as the unit type. When the material parameters are defined, take the most basic steel as an example, the modulus of elasticity is set to 2e5 and Poisson’s ratio is 0.3. After the pre-processing is set, the mesh is divided. Due to the complexity of the components, the meshing is mainly done by free division, while the number of segments for line division is set at key locations and the minimum length of the mesh edges is set. Figure 4 shows the mesh division.

Figure 4. Schematic diagram of mesh division

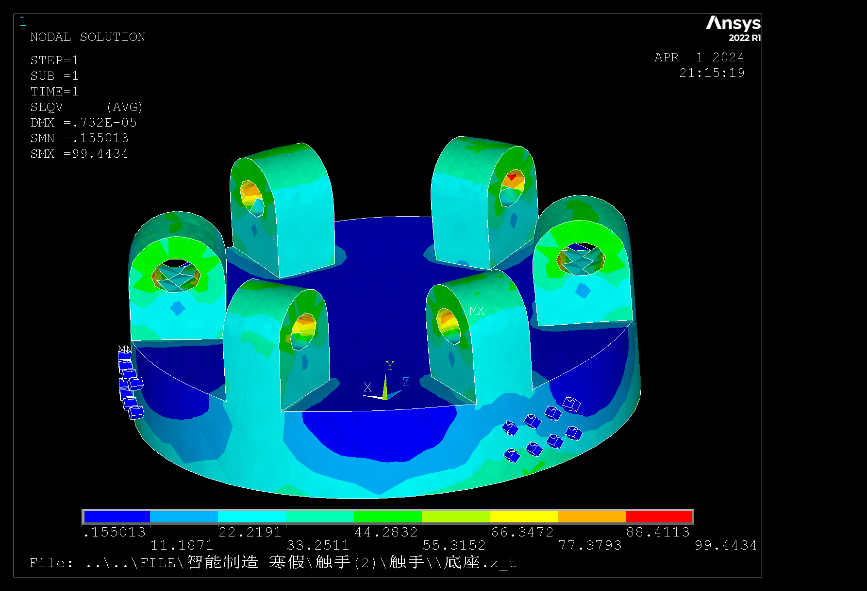

Once the meshing is completed, the static analysis is started. The bottom of the base is completely fixed, and pressure is applied to the upper part of the six connection holes to simulate and solve for the sudden contraction force. As shown in Figure 5, the nodal solution is finally obtained.

Figure 5. Schematic diagram of the hydrostatic solution

4.2. Stability Analysis

In the bionic tube worm robot, when the bionic tentacle retracts at a high frequency and high speed, the high-frequency shock it causes will cause some damage to the structure and material of the robot, thus bringing challenges to the stability of the robot structure and function. This can be ameliorated by the multilayer membrane structure of Tubeworm. Tubeworm’s unique multilayer structural sector-worm membrane provides a strong and stable substrate through which the membrane not only resists thousands of strokes, but also helps the sector-worm regain stability after ultra-fast retraction. Here, modal analysis and harmonic response analysis are used to simulate the stability of multilayer membranes [7].

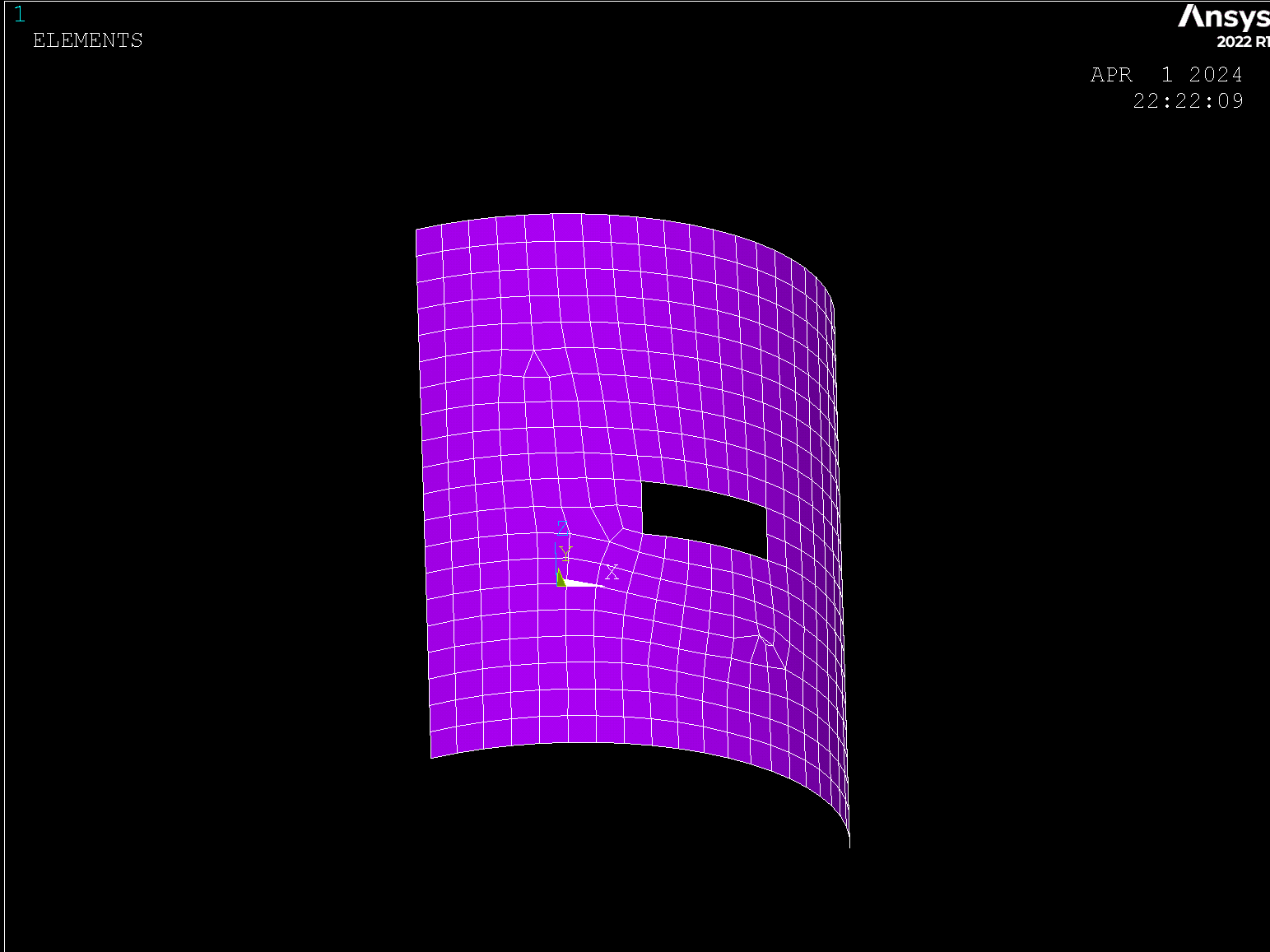

In the modal analysis and harmonic response analysis, the structural is selected as the analysis type, and Shell is added as the unit type. When the material parameters are defined, take the most basic steel as an example, the modulus of elasticity is set to 2e5, Poisson’s ratio is 0.3, and the shell is defined as three layers, all of which have a thickness of 6mm. After the pre-processing is completed, modeling is performed, first constructing contour lines to form a surface, and then dividing the mesh, as shown in Figure 6:

Figure 6. meshing of inner surface

In the modal analysis, the post-processor modal order is set to the first ten orders, constraints are created, the bottom of the frame is fully constrained and solved. The first ten orders of intrinsic frequencies are shown in Table 1:

Table 1. first ten orders of intrinsic frequency of the inner surface

SET | TIME/FREQ | LOAD STEP | SUBSTEP | CUMULATIUE |

1 | 2.1173 | 1 | 1 | 1 |

2 | 2.9297 | 1 | 2 | 2 |

3 | 5.2117 | 1 | 3 | 3 |

4 | 7.9712 | 1 | 4 | 4 |

5 | 9.4765 | 1 | 5 | 5 |

6 | 10.437 | 1 | 6 | 6 |

7 | 11.669 | 1 | 7 | 7 |

8 | 14.297 | 1 | 8 | 8 |

9 | 14.928 | 1 | 9 | 9 |

10 | 18.355 | 1 | 10 | 10 |

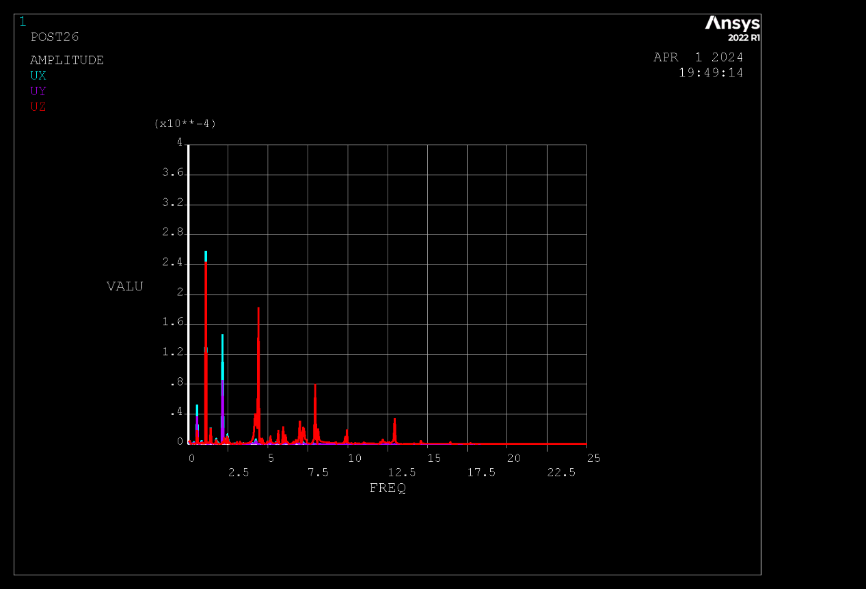

In the harmonic response analysis, the harmonic response analysis is selected as the type of analysis in the post-processor, while amplitude+phrase is selected as the analysis method. In addition, the allowable error is set to 1e-8, the frequency interval is set, the frequency interval is selected to be 0 to 50 in 500 STEPS, and the error was set to 0.001. Then proceed with solve operation. For time-domain post-processing, the xyz displacement of a node is selected as a variable in the notch to create a graph, and the results are shown in Figure 7:

Figure 7. solve for harmonic response analysis

5. Conclusion

In conclusion, the paper corroborates the reliability of bionic tubeworm robots as long-term undersea exploration entities, particularly emphasizing their capability to safeguard the high-value, delicate sensors they encompass. Initially, the study elucidates the correlation between the structural folds within the tubeworm’s inner wall and the stability requisite for its periodic retraction over time. Subsequently, through empirical validation, it identifies several factors critical to the tubeworm’s retraction process. Tubeworms have developed biological mechanisms to minimize resistance during swift retraction phases, including the flattening of pinnae on their radiolucent tentacles and the compression of cuneiform ridges, throughout their prolonged natural evolution. Concurrently, tubeworms possess advanced longitudinal muscles, pivotal for retraction.

Drawing inspiration from the tubeworm’s anatomy, the paper devises a robot equipped with distinctive features: a mechanism facilitating rapid retraction, mirroring the design principles observed in tubeworms; and a radial tentacle-like sensory apparatus that enhances detection range, capable of retracting sensors upon stimuli detection, subsequently centering and compacting them via the retraction mechanism. Furthermore, the robot features a smooth inner wall designed to reduce drag, enhancing operational efficiency.

Our contribution to the field of oceanic exploration, though modest, underscores the significance of robotic aids in oceanographic research and monitoring. In recent years, many people have also proposed their own research on the means of protection for marine robots, for example: An et al. proposed an uncertain moving obstacle avoiding method for a spherical underwater robot. This approach facilitates the protection of robots from damage during locomotion, thereby enhancing their agility. Liu et al. worked on defense against spy-robot which emphasizes on the protection of underwater acoustic sensor network. Xiang et al. However, the development of marine robots, particularly for sensor protection, remains a nascent area of study, prompting our initiative to leverage the self-protective traits of tubeworms. Presently, our investigation remains in the conceptual and simulation phase. To further substantiate the efficacy of the bionic tubeworm robot, future research will involve the fabrication of a physical prototype for real-world environmental testing.

The experimentation phase has profoundly illuminated the potential lessons inherent in nature. Millennia of evolution have honed the survival mechanisms and selection processes that underscore the intrinsic logic and study-worthy value of all living organisms. Consequently, our exploration into biomimetic robotics not only contributes to technological advancement but also deepens our understanding of the natural world’s complexities.