1. Introduction

In the realm of sugarcane cultivation, China has progressively embraced mechanized planting, which, compared to manual cultivation, enhances yield and increases income. The sugarcane planting machinery needs to adapt to China’s circumstances, requiring enhanced reliability, efficiency, lifespan, as well as intelligence and efficiency in sugarcane planting. Currently, two main types of sugarcane planting machines are promoted and utilized in China: the real-time cutting planting machine and the pre-cut planting machine [1,2]. Interruptions in seed feeding during the operation of these machines result in significant sugarcane seed leakage.

The issue of seed leakage in pre-cut sugarcane transverse planting machines remains at the experimental research stage domestically and has not been resolved in practical applications. Therefore, achieving real-time reseeding is a crucial bottleneck problem urgently needing resolution in the sugarcane production process.

2. Current Research Status of Seed Leakage Detection Technology at Home and Abroad

Accurate detection of seed leakage during the operation of pre-cut sugarcane transverse planting machines is a prerequisite for achieving real-time reseeding. Commonly used methods both domestically and abroad involve using components such as photoelectric sensors and ultrasonic sensors to detect seed flow.

Bahram Besharati [3] developed an infrared sensing system to monitor seed flow. The processor analyzes voltage changes in response to fluctuations in light intensity, enabling the monitoring of continuous seed leakage behavior and evaluation of planter performance.

Domestically, Lei Xiaolong [4] utilized diffuse reflection photoelectric switch sensors and Hall sensors to create a seed leakage detection system. This method features a simple design, compact size, and precise detection capabilities.

Both domestic and foreign scholars continually design and optimize sugarcane planter seeding mechanisms. However, seeders still experience leakage, significantly reducing yield per unit area. To address seed leakage in sugarcane planting machines during operation, developed countries overseas employ methods like stacking sugarcane seeds, while domestic scholars design auxiliary seeders and develop real-time reseeding technology to solve this issue.

3. Design of Real-Time Reseeding Mechanism and its Control System

The issue of seed leakage in sugarcane planting machines has become a critical bottleneck in the sugarcane production process, and reseeding technology is key to solving seed leakage issues in pre-cut sugarcane transverse planting machines. However, the primary challenge remains that this technology is currently in the experimental research stage and has not yet resolved seed leakage issues in sugarcane planting machines in practical applications.

This study primarily focuses on improving existing reseeding technologies proposed by various research teams for seed leakage in sugarcane planting machines, addressing specific issues: First, the large volume of the real-time reseeding device occupies excessive space on the sugarcane planting machine. Second, it fails to address continuous multiple instances of seed leakage in the seeding mechanism.

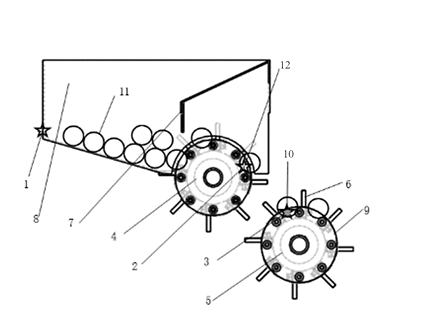

Figure 1. Pre-cut Sugarcane Transverse Planting Machine

Figure 2. Seeding Mechanism Structure

The primary research content is as follows:

1. Designing a compact and efficient real-time reseeding mechanism and its control system for the second-generation pre-cut sugarcane transverse planting machine developed by the team members (Figure 1).

2. Conducting discrete element simulation analysis of the designed real-time reseeding mechanism to identify significant factors affecting the stability of the seed backup process, thereby providing references for subsequent platform experiments.

3. Devising real-time reseeding strategies to address the issue of continuous multiple seed leakages in the seeding mechanism.

4. Carrying out bench-scale experiments to determine the reseeding qualification rate and efficiency of the real-time reseeding mechanism.

3.1. Design of Real-time Reseeding System Structure

Based on the structure of the seeding mechanism of the pre-cut sugarcane transverse planting machine shown in Figure 2, which is compact, the internal space available for installing the real-time reseeding system is limited. This research designs the mechanical structure of the real-time reseeding system as a dual rake roller mechanism, as depicted in Figure 3a. The real-time reseeding mechanism is installed above the sugarcane seed conveying chain of the seeding mechanism, with two rake rollers: the backup seeding roller and the reseeding roller.

The function of the backup seeding roller is to orderly dispense stored sugarcane seeds from the seed box into the sugarcane groove of the reseeding roller, ensuring an adequate seed reserve and enhancing reseeding efficiency. The reseeding roller stores prepared sugarcane seeds and supplements the leaked seeding groove on the seeding mechanism’s conveying chain, ensuring an efficient real-time reseeding effect.

|

|

(a) Dual rake roller mechanism | (b) Roller-rake structure |

Figure 3. Real-time Reseeding Mechanism. 1. Photoelectric sensor 2. Photoelectric sensor 3. Photoelectric sensor 4. Backup seeding roller 5. Reseeding roller 6. Reseeding roller rake 7. Cane stopper 8. Seed box 9. Reseeding groove 10. Reseeding sugarcane seed 11. Stored sugarcane seed 12. Prepared sugarcane seed

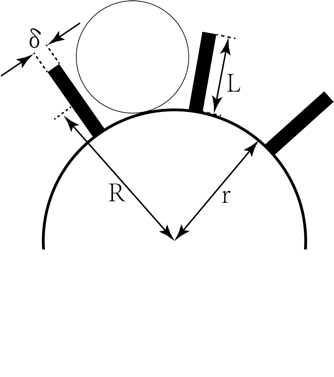

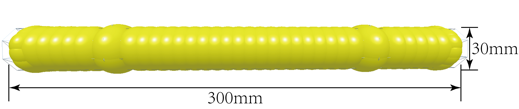

To determine the dimensions of the rake roller mechanism, Middle Cane No. 18 was selected as the experimental sugarcane variety. Through sampling measurements, it was determined that the maximum diameter of the sugarcane seed (dmax) was 36mm, with an average diameter of 30mm and an average length of 300mm. To achieve uniform and effective seeding, the rake tooth height (L) is 10% larger than the maximum diameter of the sugarcane seed. The calculation formula for the rake roller dimensions is depicted in Figure 3b.

\( 2r+2L≤200 mm\ \ \ (1) \)

\( R=r+\frac{L}{2}\ \ \ (2) \)

\( L=1.1{d_{max}}\ \ \ (3) \)

\( \bar{d}+δ \lt \frac{2πR}{y} \lt {d_{max}}\ \ \ (4) \)

In which:

\( r \) ——Rake Roller Radius, mm

\( R \) ——Distance from Rake Roller Center to Rake Tooth Center, mm

\( L \) ——Rake Tooth Height, mm

\( δ \) ——Rake Tooth Thickness, mm

\( y \) ——Number of Rake Teeth

To achieve stable reseeding for different sugarcane diameters, to realize a stable reseeding effect, the following values are selected: Rake Tooth Height (L) = 40mm, Thickness (δ) = 5mm, Rake Teeth Count (y) = 8, Rake Roller Radius (r) = 50mm.

3.2. Real-time Reseeding System Structural Simulation Test

To improve the stability and reliability of the reseeding process, the EDEM software is employed to perform discrete element simulation analysis of sugarcane seeds during the operation of the reseeding mechanism. This analysis aims to determine the impact of linear speed on stable reseeding and identify optimal working parameters for the rake roller.

Figure 4. Discrete Element Simulation

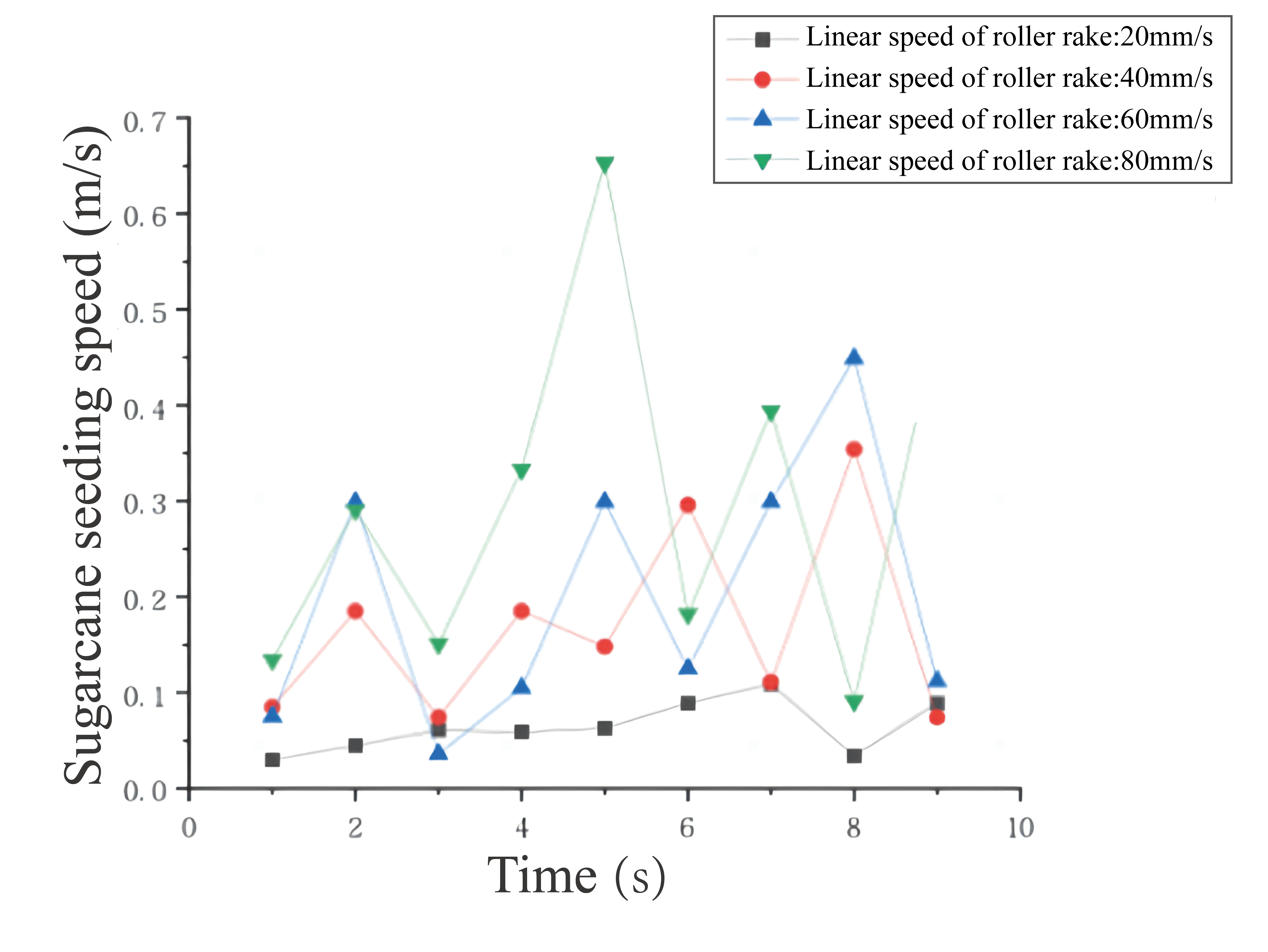

Figure 5. Sugarcane Seed Transmission Speed Curve

SolidWorks software is used for 3D modeling of the reseeding system, followed by importing the model in .step format into the EDEM software for simulation analysis. As per references [5,6], the materials of the seed box and rake roller are set as steel with a Poisson’s ratio of 0.3, shear modulus of 7×10^10 Pa, and density of 7800 kg/m³. The rake tooth material is set as soft PVC with a Poisson’s ratio of 0.32, shear modulus of 5.68×10^6 Pa, and density of 1282 kg/m³. A spherical assembly is used to simulate the sugarcane seeds in the EDEM software, as shown in Figure 4. According to literature [7], the sugarcane seeds are set with a density of 1100 kg/m³, shear modulus of 10.82×10^6 Pa, and Poisson’s ratio of 0.33 [8]. The roller-rake linear speed factor is designed for 4 levels.

During single-factor simulation tests, the influence of different linear speeds of the rake roller on the change in sugarcane seed transmission speed over time is shown in Figure 5. Variance analysis of the sugarcane seed velocity data indicates that the linear speed of the rake roller significantly affects seed backup stability. As the rake roller linear speed increases, the sugarcane seed velocity also increases. However, the stability of sugarcane seed particle velocity decreases. When the rake roller’s linear speed is around 20mm/s, the sugarcane seed velocity remains relatively stable. This provides a theoretical basis for determining the rake roller’s linear speed in the next bench-scale experiments.

3.3. Design of Real-time Reseeding System Operation Strategy

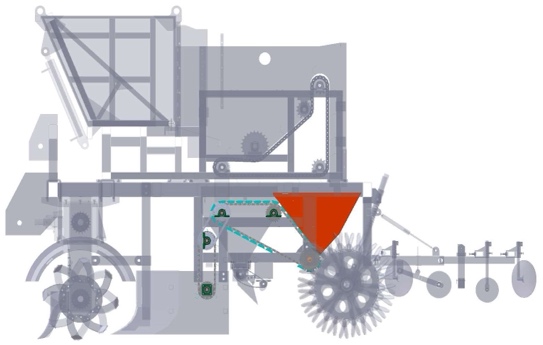

The real-time reseeding system is installed above the seeding chain of the seeding system shown in Figure 6. A positioning magnet is installed on one side of the seed groove, along with a sugarcane seed detection window. Hall sensors determine the seed groove position, and photoelectric sensors detect seed leakage in the seed groove.

Figure 6. Installation of Seeding System

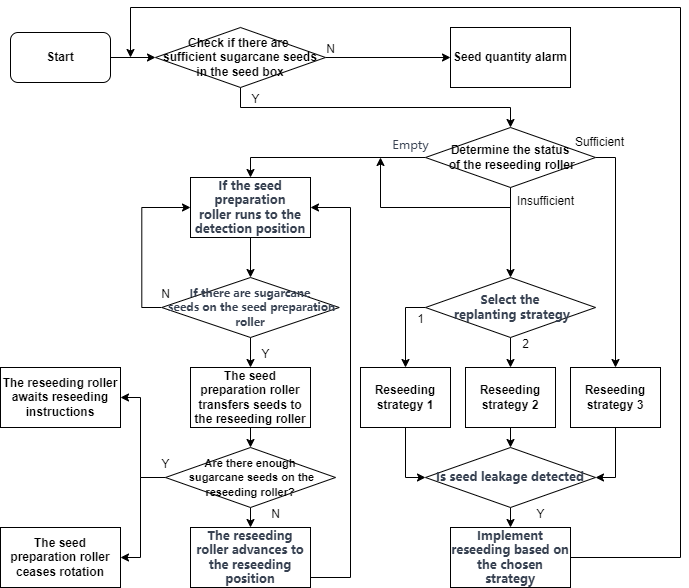

Figure 7. Workflow of Real-time Seeding System

The workflow of the real-time reseeding system, as depicted in Figure 7, consists of two main stages: seed backup and reseeding. In the seed backup stage, when the seed box contains sufficient sugarcane seeds, if the reseeding roller has unseeded seed grooves, the stepper motor drives the backup seeding roller to transfer sugarcane seeds from the seed box to the seed grooves of the reseeding roller. The side-mounted photoelectric sensor on the reseeding roller detects the seeding status, and the controller determines the adequacy of seeds on the reseeding roller. In the reseeding stage, ensuring the presence of sugarcane seeds on the reseeding roller, when there is seed leakage in the seed storage groove of the sugarcane planting machine’s seed storage slot, the controller instructs the reseeding roller drive motor to execute the corresponding reseeding strategy, supplementing sugarcane seeds into the leaked seed storage groove. To prioritize effective real-time reseeding, the reseeding stage takes precedence over the seed backup stage. When the quantity of sugarcane seeds in the seed box is insufficient, the real-time reseeding system triggers an alarm and halts operation.

3.4. Real-time Seeding Control System Design

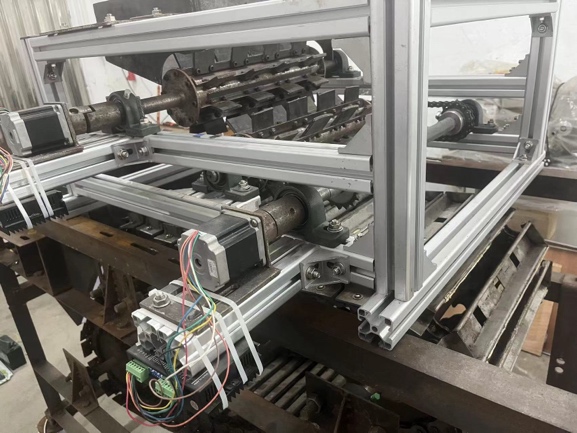

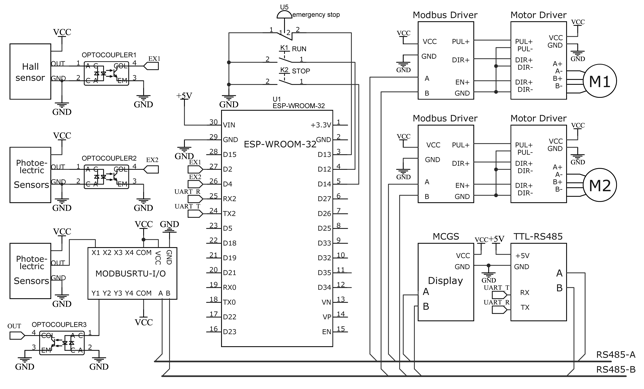

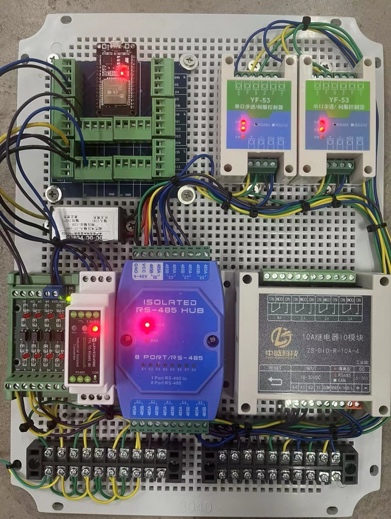

The real-time seeding system comprises the backup roller, seeding roller drive motor, optical sensors for backup and seeding storage, seeding position and missed seeding sensors within the seeding system, and a seeding information display screen, among other electrical components. To ensure stable operation, simplify the electrical connection wiring complexity, and reduce the control system design cost, the seeding control system circuit adopted the design illustrated in Figure 8, as depicted in the control system diagram in Figure 9.

Figure 8. Circuit Schematic

Figure 9. Control System

The core controller of the control system is designed using the ESP32-D0WD-V3 microcontroller. With a maximum clock frequency of 240MHz and multi-threading capabilities, it avoids signal or data latency during processing, enhancing data acquisition and real-time execution accuracy.

The control system uses RS-485 bus with ModbusRTU communication protocol for data transmission. Due to the harsh working environment of agricultural machinery, especially electrical equipment, RS-485 offers strong common-mode interference resistance, easily deployable using twisted-pair cables. The Modbus communication protocol operates in a master-slave mode, allowing simple and versatile expansion of the real-time seeding control system’s functionalities.

The backup roller and seeding roller are driven by 57-type two-phase eight-wire stepper motors. To improve control efficiency and simplify electrical connections, two stepper motors use YF-53 ModbusRTU pulse controllers for motion control.

Digital input and output controllers supporting ModbusRTU protocol gather outputs from optical and Hall sensors and produce alarm signals. The core controller can read sensor statuses through Modbus master queries or send alarm signals via ModbusRTU commands to execute operations through the digital input-output controller.

The Kunlun Tongtai TPC7022Et embedded integrated touch screen serves as the real-time seeding system information display. The touchscreen is configured as a slave under the ModbusRTU protocol, allowing the core controller to read and write touchscreen data.

The real-time seeding control system involves multiple devices using the ModbusRTU protocol over the RS-485 bus. To reduce interference during data transmission and enhance stability during seeding operations, an RS-485 splitter connects the master-slave devices to the communication bus.

Considering the practical operating environment of agricultural machinery, the control system operates using a DC24V power supply, providing power to stepper motor drivers, stepper motor controllers, optical sensors, Hall sensors, optocouplers, digital input-output controllers, touchscreen, and RS-485 splitter. A DC24V to DC12V, 2A buck converter powers the ESP32-D0WD-V3 microcontroller and TTL level to RS-485 module.

4. Experiment Verification

4.1. Experimental Conditions

The real-time seeding system used in this experiment was installed above the simulated planting platform of the pre-cut sugarcane lateral planting machine. The drive motor and sensors of the seeding system were connected to the control box via harness. Medium-sized sugarcane No. 18 seeds were used, with an average diameter of 30mm and an average length of 300mm. The seeding system’s seed box contained 50 segments of seeds. The running speeds of the planting chain were set at 0.1m/s, 0.2m/s, and 0.3m/s, with the seeding chain raised 50 times. The missed seeding rate was compared with and without the intervention of the real-time seeding system. The formula for calculating the missed seeding rate was as follows:

\( P=\frac{E}{N}×100\% \)

Where P represents the missed seeding rate, E indicates the number of missed seeds, and N is the number of chain elevations.

4.2. Experimental Results and Analysis

Based on the experimental results in Table 1, an analysis of the missed seeding rates in the planting chain slots was performed. As the linear speed of the planting chain increased, the missed seeding rate in the planting chain slots gradually rose. This was attributed to higher chain speeds resulting in reduced seed stability within the chain slots, making seeds more prone to slipping and decreasing the efficiency of seed elevation.

Comparing the missed seeding rates between the installation and absence of the real-time seeding system, at a planting chain speed of 0.1m/s, the real-time seeding system reduced the average missed seeding rate by 6%.

Table 1. Result

Planting Chain Speed | Missed Seeding Rate without System(%) | Missed Seeding Rate with System(%) | Average Decrease in Missed Seeding Rate(%) | ||||

Exp. 1 | Exp. 2 | Exp. 3 | Exp. 1 | Exp. 2 | Exp. 3 | ||

0.1m/s | 8 | 6 | 6 | 0 | 2 | 0 | 6 |

0.2m/s | 8 | 6 | 10 | 6 | 2 | 2 | 4.67 |

0.3m/s | 8 | 10 | 10 | 4 | 6 | 4 | 4.63 |

With increased planting chain speed, the efficiency of the real-time seeding system gradually decreased. This was due to higher chain speeds leading to increased missed seeding rates, resulting in continuous missed seeding in the chain slots. In future improvements, adjustments to the seeding roller’s speed within the seeding mechanism should correspond to the running speed of the planting chain.

5. Conclusion

Through the study of the current situation of missed seeding in pre-cut sugarcane lateral planting machines, a real-time seeding system designed specifically for these machines was developed to enhance their planting rates. This research encompassed the design of the seeding system’s mechanical structure and control system. Discrete element simulation experiments analyzed the influence of seeding roller line speed on seeding stability. The bench test indicated that at a planting chain speed of 0.1m/s, the real-time seeding system effectively reduced the missed seeding rate by 6%, confirming the feasibility of the real-time seeding system.

With the nation vigorously advocating agricultural mechanization, sugarcane mechanical planting is becoming the mainstream method for sugarcane cultivation. In terms of increasing planting rates and precision planting while reducing manual costs, continuous research and experimentation aim to design a real-time seeding system that aligns more effectively with pre-cut sugarcane lateral planting machines, continually enhancing their planting efficiency and qualification rates.

Acknowledgments

This research acknowledges the support provided by the National Natural Science Foundation project (52165009).