1. Introduction

In recent years, the advancement of flexible strain sensors and flexible pressure sensors has been rapid. These sensors hold significant potential in various applications, such as intelligent wearable devices, clinical disease diagnosis, health monitoring, electronic skin, and soft robots [1]. Due to the diverse types of sensors, their functions in applications can vary. Based on their mode of operation, capacitive, piezoresistive, and piezoelectric flexible pressure sensors have been identified as the three most popular types [2]. This work primarily focuses on the research status and current challenges of different flexible pressure sensors, with an emphasis on multi-mode functions, innovative structural designs, and overall performance improvements as future development directions.

Flexible pressure sensors are a key sensor technology with vast potential and wide application prospects across various fields [3]. Their unique properties and flexibility enable them to adapt to complex shapes and surfaces, allowing highly sensitive pressure detection and measurement [2]. With the rapid advancement of technology, flexible pressure sensors have become a prominent research area. This paper aims to introduce the principles, classifications, applications, and development trends of flexible pressure sensors.

To investigate the operating principle of flexible pressure sensors, this paper first reviews the fundamental working mechanism of the sensors, which mainly consist of conversion elements, sensitive elements, and measurement circuits, explaining how they achieve pressure detection and measurement [4]. The pivotal role of flexible materials in sensor design and their advantages over traditional rigid sensors will also be explored. Subsequently, the paper categorizes flexible pressure sensors, mainly into piezoresistive, capacitive, and piezoelectric types, to facilitate a better understanding of their characteristics and application scenarios. This forms the basis for the subsequent discussion on the use of flexible pressure sensors in various fields.

Next, the paper focuses on the application of flexible pressure sensors in diverse fields. For example, in healthcare, Kim et al. developed a flexible pressure sensor with a wide range based on a thin porous elastomer sponge coated in a network of carbon nanotubes (CNT) [5]. In the realm of wearable devices, Hu et al. utilized nano carbon black as a conducting material to create a high-performance piezoresistive pressure sensor [6]. Additionally, there are numerous applications in industrial and artificial intelligence fields [7]. The paper also covers the trends in the development of flexible pressure sensors, with a particular focus on manufacturing technologies, sensor performance, and trends in versatility and integration. It delves into innovations in new materials, improvements in manufacturing methods, enhancement of sensor performance, and integration with other sensors and electronic components.

Finally, the paper presents a comparative analysis of these sensors based on their materials and discusses the advantages and drawbacks of various sensor types. The application and development trends are summarized, and the future potential and prospects of flexible pressure sensors are discussed. Technical challenges and limitations are addressed, and potential solutions and future directions are proposed. The comprehensive review provided in this paper aims to offer readers a thorough understanding of the fundamental principles of flexible pressure sensors, different types of classifications, wide application fields, and future development trends. It is anticipated that flexible pressure sensors will play a crucial role in various industries and continue to advance science and society.

2. Principle of the flexible pressure sensor

2.1. Basic principle of the pressure sensor

A sensor is a type of equipment comprising converting elements, sensitive components, and a measurement circuit, capable of converting non-electric physical quantities into electrical quantities and parameters. The sensitive component plays a crucial role and is composed of a material that is highly responsive to various physical quantities such as force, temperature, color, sound, and chemical elements [4]. A pressure sensor is a type of sensor made up of force-sensitive materials. It requires a measurement standard in close proximity to the physical quantity being measured to convert it into the desired physical quantity. The sensitive elements can be directly measured, and the corresponding non-electric quantity is transmitted and then converted into an electrical quantity and set of electrical parameters. The materials used to create sensitive elements are typically responsive to physical phenomena like sound, temperature, and color. When the sensitive element detects a signal, it is often a rather weak signal, requiring the application of conversion elements and the combination of auxiliary circuits to complete the measurement. The working principle of the sensor is illustrated in Figure 1.

Figure 1. Sensor working principle flow [4].

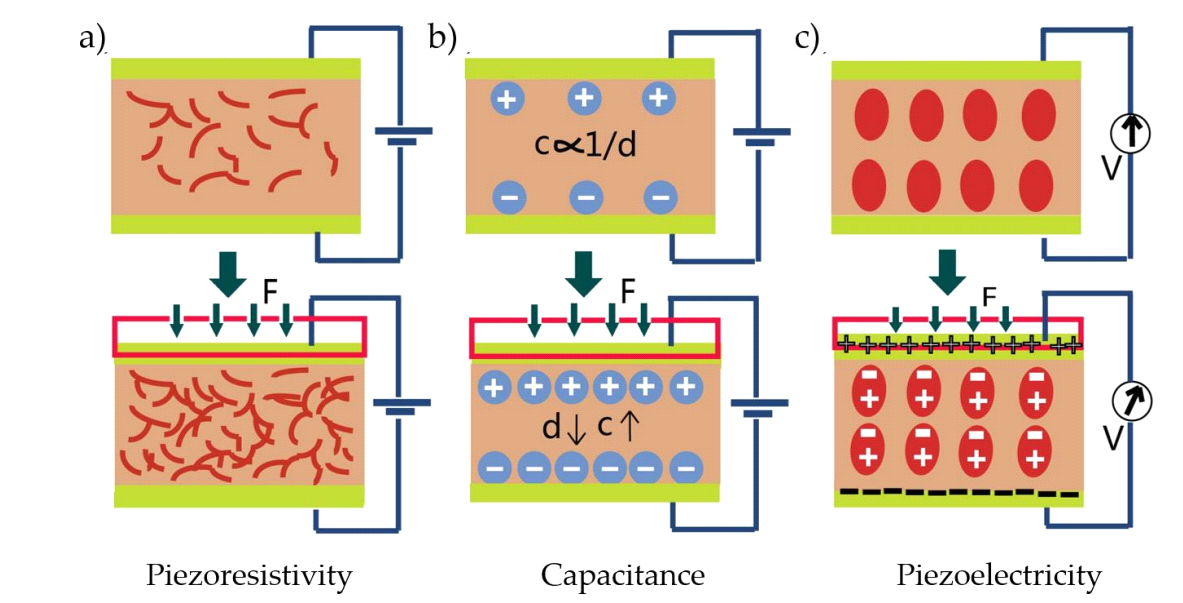

The term “pressure sensor” dates back to 1945 when Smith (C.S. Smith) discovered the piezoresistance effect in germanium and silicon, which refers to the change in resistance of a material under mechanical force. Utilizing this principle, the first pressure sensor that converted force signals into electrical signals was developed [3]. Over time and with technological advancements, pressure sensors have become more diverse and functional. They find widespread applications in entertainment, industrial control, automotive engineering, rehabilitation medicine, and other fields. Based on different technologies and sensing methods, pressure sensor principles can be categorized into common principles such as piezoresistance effect, piezoelectric effect, and capacitor principle, as well as less common principles like triboelectric effect [8]. Figure 2 illustrates three common transduction mechanisms and representative devices.

Figure 2. Diagrammatic representation of the three typical conduction mechanisms:a) piezoresistive type, b) capacitive type, c) piezoelectric type [2].

2.2. Working principle of the flexible pressure sensor

The flexible pressure sensor is a type of flexible sensor made from elastic materials or flexible films. Its operation relies on the deformation characteristics of these materials when exposed to external pressure. Typically, conductive materials, such as conductive ink or metal wire, are embedded in the sensor structure. When the flexible material or film undergoes deformation due to external pressure, the resistance of the conductive material changes accordingly. The pressure level can be estimated by measuring this change in resistance.

Flexible pressure sensors generally operate on similar principles as ordinary pressure sensors, but their advantage lies in their soft, thin, and flexible nature, allowing them to adapt to various surface shapes. Consequently, they find wide applications in fields such as human-computer interaction, medical equipment, and robot technology.

The flexible pressure sensors can be categorized based on their working principles:

1. Capacitive Principle: Capacitive sensors translate physical pressure into capacitance measurements. They consist of two side-by-side metal plates with a certain distance and a medium between them. The capacitance value changes with even a minor alteration in the spacing between the plates when pressure is applied to the sensor. The magnitude of the pressure can be determined by monitoring the change in capacitance value [9].

2. Piezoresistive Principle: Piezoresistive sensors convert physical pressure into resistance values. The piezoresistive element usually comprises a metal film and a support film that undergo elastic deformation when subjected to physical pressure, thereby altering the resistance value. The principle behind their operation is the law of resistance, where the resistance R decreases with decreasing cross-sectional area S and increases with length L and resistivity ρ. The impacted pressure’s magnitude is calculated by measuring the change in resistance value [10].

3. Piezoelectric Principle: Piezoelectric pressure sensors typically consist of piezoelectric ceramic material, a preamplifier, filter circuit, gain circuit, AD converter, and digital signal processor. The basic principle utilizes the piezoelectric effect to measure pressure. When pressure is applied to the piezoelectric ceramic material, it generates an electric charge that is proportional to the applied pressure. The piezoceramic material is fixed to the sensor’s structure, and when pressure is applied, it generates strain, leading to the generation of an electrical charge that is measured and converted into an electrical output. Hence, the piezoelectric pressure sensor is essentially a charge sensor [11].

Apart from these three principles, there are other principles, such as the capillary principle and the fiber optic principle, used for different types of pressure sensors. Ordinary pressure sensors, with excellent precision, stability, and reliability, are widely used in industrial control, automobile engineering, aerospace, and other sectors.

It is essential to mention that the design and manufacturing process of flexible pressure sensors can influence their precise operating principle. Therefore, it is advisable to refer to the technical documentation and related information provided by the manufacturer for a specific application to understand the working principle and performance characteristics of the flexible pressure sensor.

2.3. Effect of the properties of flexible materials on sensor performance

Flexibility and Bendability: Flexible materials exhibit high flexibility and bendability, enabling the sensor to conform to various shapes and surfaces, thereby increasing its applicability and range of use. For instance, flexible sensors can be seamlessly fitted to curved surfaces or human skin, resulting in more precise and natural measurements.

Stretchability: Flexible materials typically possess a certain level of stretchability and can deform without rupturing under stress. This is crucial for sensors designed to measure stretch or compression. The stretchability of flexible materials allows the sensor to function effectively when subjected to strain and provides accurate measurement data.

Thin and Lightweight: Flexible materials are usually thin and lightweight, facilitating compact sensor designs with reduced weight. This attribute proves highly advantageous in applications that necessitate sensors to fit within limited space or require portability.

Transparency: Some types of flexible materials, such as flexible transparent conductive materials, offer transparency. This property enables the sensor to be placed on transparent surfaces like windows and touch screens without compromising visual effects. Transparent sensors find utility in applications such as touch, pressure, and light sensing.

Durability: Flexible materials generally possess excellent durability and wear resistance, allowing them to withstand long-term use and repeated bending without failure. This durability is essential for applications requiring long life and stable performance.

Overall, the characteristics of flexible materials empower sensors to adapt to diverse shapes and surfaces, thereby providing more versatile applications with enhanced transparency, durability, and lightweight properties. These features confer numerous advantages to sensor design and application, driving the advancement of flexible sensor technology.

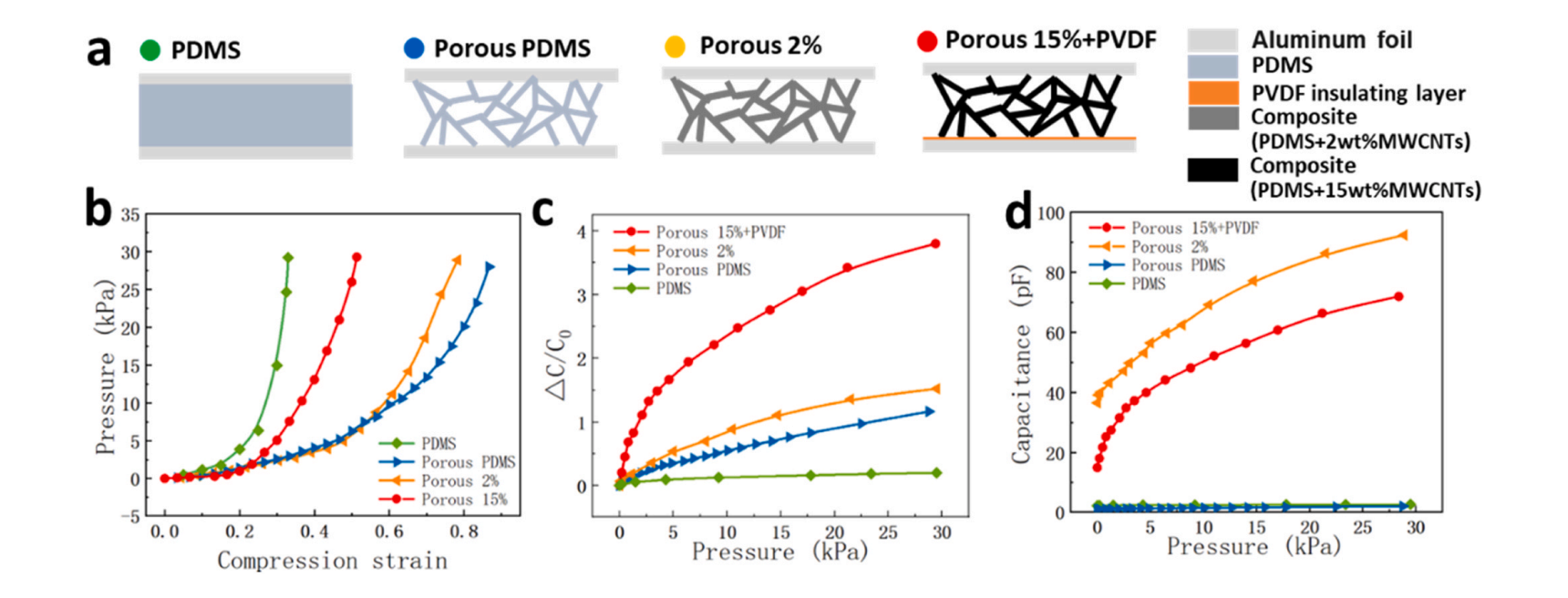

For example, Zhong et al. developed a flexible capacitive pressure sensor using an ultra-thin porous polyvinylidene fluoride (PVDF) dielectric layer and a porous electrode doped with high concentrations of carbon nanotubes (CNT) [12]. The capacitive sensor devices were fabricated using two different methods, as illustrated in Fig. 3a. Fig. 3b demonstrates that porous polydimethylsiloxane (PDMS) can withstand greater compression strain compared to solid PDMS under the same pressure. The pressure-strain curves are depicted in Fig. 3c, showing the change in capacitance versus pressure for the capacitive pressure sensors. Fig. 3d presents the outcomes after normalizing the capacitance change by the original capacitance.

Figure 3. (a) Diagrammatic representation of various capacitive pressure sensor types. (b) The porous structure of PDMS with varying CNT doping shows a pressure-strain curve. (c) The absolute capacitance of various sensors’ pressure response. (d) The relative capacitance changes in response to pressure for different sensors [12].

2.4. Sensor preparation process

Early Mechanical Sensors: In the early stages, pressure measurements heavily relied on mechanical sensors such as pressure gauges and spring dynamometers. These sensors inferred pressure values by measuring the deformation of elastic elements.

Resistive Sensors: In the early 20th century, resistive sensors started to be employed in pressure measurement. These sensors utilize the principle of pressure-induced resistance changes for measurement, with commonly used variants being strain patch sensors and resistance strain sensors.

Capacitive Sensors: The 1940s witnessed the introduction of capacitive sensors into the field of pressure measurement. These sensors measure pressure by detecting changes in capacitance values caused by pressure. They offer advantages such as high accuracy and stability.

Quartz Pressure Sensors: In the 1960s, quartz pressure sensors made their appearance. These sensors employ the elastic properties of quartz crystal for pressure measurement, featuring high precision, corrosion resistance, and strong temperature stability.

Semiconductor Pressure Sensors: In the late 1970s and early 1980s, semiconductor pressure sensors emerged and gradually became the mainstream technology. These sensors utilize the piezoresistive effect of semiconductor materials for measurement, offering advantages like high reliability, low cost, fast response, and compact size.

Microelectromechanical System (MEMS) Pressure Sensors: The 1990s witnessed the development of MEMS technology, which spurred the emergence of miniaturized pressure sensors. MEMS pressure sensors utilize microprocessing technology to manufacture tiny structures and sensor components on silicon chips, resulting in highly integrated, low power consumption, and cost-effective sensors.

Application of Emerging Technologies: Ongoing advancements in science and technology have led to the application of emerging technologies in pressure sensor development. For example, fiber-optic sensors utilize the optical characteristics of fibers for pressure measurement, while flexible sensors made of adaptable materials cater to measurement requirements on curved surfaces.

Thus, the future focus of sensor development should heavily emphasize flexible sensors. The development of biosensors, pH sensors, and flexible optical sensors is still in its early stages, promising inventive applications in wearable sensors, micromotion sensing, and artificial skin.

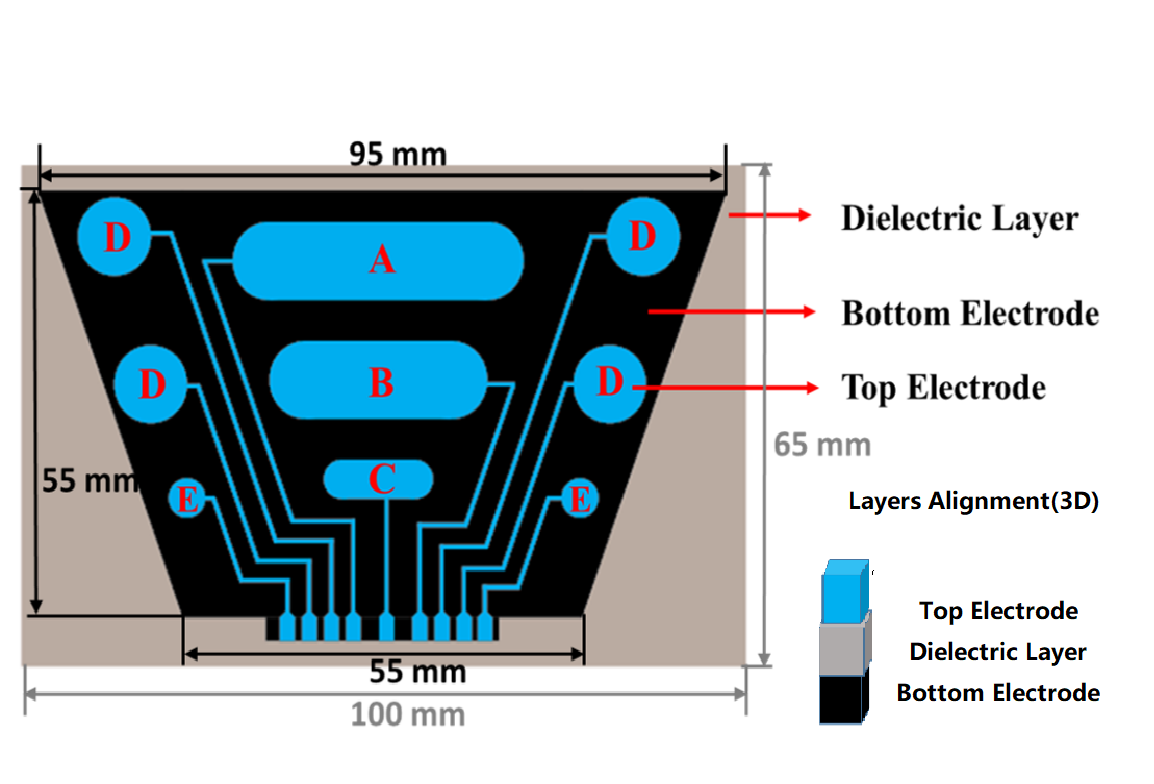

Maddipatla et al. used screen printing technology and PDMS as the medium layer to create a capacitive pressure sensor based on flexible carbon nanotubes (CNT) [13]. This research demonstrates the possibility of producing flexible and effective pressure sensors with carbon nanotube electrodes, suitable for applications in robotics, sports, automotive technology, and other industries. The process involves designing a stainless steel wire mesh frame on a Microscreen, followed by direct printing of carbon nanotube ink on the PDMS dielectric layer as the top and bottom electrodes. The sensor’s principle is illustrated in Figure 4, where A, B, C, D, and E represent electrodes of different dimensions in the top layer.

Figure 4. Layer alignment in the CNT pressure sensor schematic [13].

3. Research status of common flexible pressure sensors

Capacitive, piezoresistive, and piezoelectric pressure sensors are among the most widely used types. Their significant role in wearable electronics has led to extensive applications in various sectors, including physiological signal monitoring and haptic feedback. The performance of flexible pressure sensors has continuously improved to meet the demands of an expanding range of applications, thanks to constant advancements in novel materials and device manufacturing.

3.1. Capacitive flexible pressure sensor

3.1.1. Principles and advantages. Capacitive flexible pressure sensors offer several advantages over other types, including high sensitivity, low power consumption, and quick response times. The capacitive pressure sensor operates based on the principle of small deformation when pressure is applied to the measured object. It usually consists of metal shrapnel and a pair of metal electrodes. External force causes the metal shrapnel to deform, changing the distance between the electrodes and the electric field strength, resulting in a change in capacitance value that enables pressure measurement.

Formula (1) is commonly used to calculate the capacitance of most capacitive sensors:

\( C=\frac{εS}{d} \) (1)

Where:

ε - the dielectric constant,

S - the overlapping area of the upper and lower plates,

d - the plate spacing.

In theory, the capacitance can be adjusted by modifying ε, A, and d.

3.1.2. Frontier research direction. The performance of capacitive flexible pressure sensors can be optimized by altering the device’s structural parameters. Variables such as the effective dielectric constant, electrode spacing, and effective positive electrode area can be adjusted to maximize performance. Several major approaches for optimization include the application of novel nanomaterials, design of innovative microstructures, and development of new composites. The following four principles can guide the optimization process:

1) Adjust the roughness of the electrode surface to modify the effective opposite area of the electrode.

2) Introduce an air layer into the electrode or dielectric layer to reduce the elastic modulus.

3) Add air or a substance with a high dielectric constant to the dielectric layer to modify the effective dielectric constant.

4) Form microcapacitance using composites in the dielectric layer to alter the overall capacitance change.

However, a common issue in performance optimization research for capacitive flexible pressure sensors is the trade-off between large detection range and high sensitivity [14]. Improving sensitivity often results in compression saturation and limited detection range, especially in the low-pressure region, leading to weak linearity. In recent years, researchers have explored gradient structure designs and mixed response mechanisms in the dielectric layer to address this issue, achieving fruitful results by significantly extending the device’s detecting range while maintaining high sensitivity. Nevertheless, hysteresis, stability, and array optimization remain challenges for practical applications of capacitive flexible pressure sensors.

3.1.3. Trends in capacitive flexible pressure sensor development in the future. Capacitive flexible pressure sensors hold great potential for extensive use in medical, robotic, automotive, and other fields due to their advantages of high precision, high sensitivity, small size, and low cost. The following elements may shape the development trend of capacitive flexible pressure sensors in the future:

1) Diversified Applications: As science and technology continue to progress, capacitive flexible pressure sensors will find applications beyond medical, robotics, and automotive fields, expanding into areas like human body sensing for smart homes and exercise monitoring for sports.

2) Improved Accuracy and Sensitivity: Although capacitive flexible pressure sensors already boast high accuracy and sensitivity, future advancements will aim to achieve even greater levels of sensitivity and precision, necessitating further design and material exploration.

3) Intelligence: Future capacitive flexible pressure sensors are expected to be more intelligent, featuring adaptability and self-repair capabilities. For example, they may automatically adjust sensitivity and address sensor damage based on the environment.

4) Multi-Mode Structure: Capacitive flexible pressure sensors are likely to adopt multi-mode structures in the future, allowing them to switch between multiple measurement modes to better suit diverse application needs.

In summary, the future of capacitive flexible pressure sensing will be characterized by increased intelligence, sensitivity, diversification, and broader application scope.

3.2. Piezoresistive flexible pressure sensor

3.2.1. Principle and advantages. The piezoresistive sensor detects pressure by measuring the change in resistance of the material, which results in an equivalent change in electrical signal. Nanomaterial-based piezoresistive sensors are commonly obtained by coating or synthesizing nanomaterials or doping them onto elastic substrates like polyethylene terephthalate (PET), PDMS, and polyurethane (PU) to form a continuous conductive network.

The law of resistance governs piezoresistive flexible sensors, stating that the resistance R of the conductor is inversely proportional to its cross-sectional area S and directly proportional to its length L and resistivity ρ, as shown in formula (2).

\( R=ρ\frac{L}{S} \) (2)

Where:

\( ρ \) - resistivity of the material used for resistance, in ohms·meters (Ω·m)

\( L \) - length of the wire wound to create resistance, in meters (m)

\( S \) - cross-sectional area of the wire wound to create resistance, in square meters (m²)

\( R \) - resistance value, in ohms (Ω)

Since its introduction, the flexible piezoresistive pressure sensor has attracted significant interest due to its straightforward design, relatively easy production process, exceptional energy efficiency, signal processing mode, and high sensitivity [15]. In recent years, there has been considerable interest in wearable sensors designed for various health monitoring applications [16]. Wearable sensors offer clear advantages compared to traditional pressure sensors. Conventional pressure sensors made of stiff materials, such as semiconductors or metals, are limited in their pressure detection and sensing range, as they can only withstand minor strains. Additionally, traditional pressure sensors are bulky and inflexible, limiting their application in practical health monitoring. In contrast, flexible wearable pressure sensors typically consist of active and supporting materials, offering great customization to fit various substrates, whether flat, curved, soft, or hard. These sensors enable real-time physiological and motor signal monitoring [17].

3.2.2. Frontier research direction. Enhancing the functionality of pressure sensors can be achieved through the preparation of porous structures using conductive materials to obtain a conductive porous active layer (e.g., hollow spheres, sponge, foam) and the surface design of microstructures (e.g., microdome, micropyramid, microcylinder). This approach helps improve the sensor’s sensitivity, detection limit, and reaction time. For example, Zhu et al. successfully prepared a high-performance pressure sensor using a microdome array with a unique glass template method [18]. The sensor utilizes a polyurethane mesopore with gradient-embedded silver nanowires (AgNW). It exhibits a high sensitivity of 6.258 k/Pa and can withstand up to 75% strain, making it suitable for expression recognition and motion monitoring applications.

In another study, Wang et al. designed and manufactured a special piezoresistive material consisting of PDMS and CNT with a porous microstructure to create a flexible and highly sensitive pressure sensor with a broad detection range [19]. The sensor shows good linear response and sensitivity to pressure in the range of 10 kPa, with the most sensitive linear response in the range of 1 kPa, reaching 10.805 k/Pa. Furthermore, the sensor demonstrates high durability and has been applied and validated in human behavior monitoring and space pressure distribution mapping. Currently, future sensor design trends are moving towards combining surface microstructure with a porous structure.

The future development objectives for piezoresistive flexible pressure sensors include achieving high sensitivity, high resolution, and high reliability, along with volume reduction, increased flexibility, and enhanced intelligence. This will further advance flexible electronic technology and enable piezoresistive flexible pressure sensors to play a crucial role in an expanded variety of applications.

3.3. Piezoelectric flexible pressure sensor

3.3.1. Principle and advantages. Piezoelectric pressure sensors are highly valuable due to their short response time, outstanding sensitivity, wide measurement range, and excellent linearity, making them widely used in industrial automation, aerospace, medical equipment, and robotics.

The principle behind piezoelectric pressure sensors is the piezoelectric sensing mechanism, which causes the deformation of the piezoelectric dielectric material, resulting in mechanical stress and a change in the dipole moment of the material, leading to an electric potential. Compared to piezoresistive and capacitive flexible pressure sensors, piezoelectric sensors have more applications and the ability to self-generate power. Currently, commonly used piezoelectric materials include polyvinylidene fluoride (PVDF) and its copolymers, lead zirconium titanate (PZT), and barium titanate (BTO). Among them, PVDF stands out due to its chemical inertness, flexibility, durability, light weight, and ease of production, making it one of the more promising materials for wearable pressure sensing devices.

3.3.2. Frontier research direction. The performance and stability of piezoelectric sensors are constrained by issues such as flaws, cracks, and poor dispersion in conventional films made from inorganic and organic compound piezoelectric materials. To address this challenge, Yang et al. developed a novel composite material by modifying barium titanate (BaTiO3, BTO) with polydopamine (PDA) as a surface enhancer and blending it with a polyvinylidene fluoride (PVDF) matrix in various ratios. This approach reduces the interface hole flaws and cracks between the two components and improves the BTO dispersion in the PVDF matrix. As a result, there is a noticeable improvement in the sensor’s sensitivity to different human body movements [20]. Additionally, the mechanical deformation abilities can be further enhanced, including stretchability, flexibility, foldability, and twistability.

Conventional pressure sensors face significant limitations in both static and high dynamic pressure detection, as they rely on a single piezoelectric or piezoresistive effect mechanism. To overcome this limitation, Lu et al. propose a novel approach that enables dual-function detection by combining piezoelectric and piezoresistive processes on a flexible sensor [21]. They construct piezoresistive units for high dynamic detection and static detection using a PVDF polymer and PVDF electrostatic spinning mat composite adorned with a graphite sheet (GS). The results demonstrate the device’s exceptional piezoresistive endurance and its ability to precisely and consistently detect each joint in the human body, highlighting the wide range of applications for wearable electronics.

4. Effect of sensor materials and types on properties

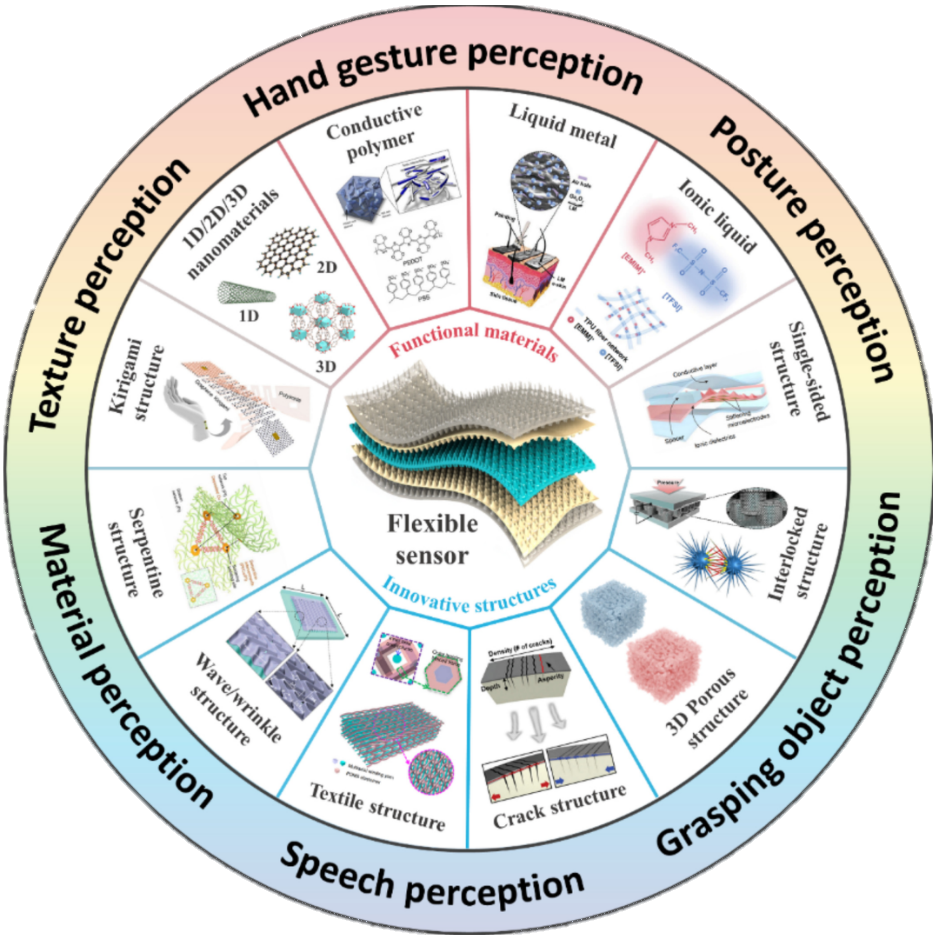

Since different sensor types exhibit varying performances and suit different application environments, this paper summarizes some sensor materials and compares the effects of these materials on performance, as shown in Table 1. Additionally, for comparison purposes, this paper lists the merits and shortcomings of several sensor types as shown in Table 2. Figure 5 displays the most well-known components and cutting-edge structures used in flexible sensors.

Table 1. Comparison of performance for Various flexible pressure sensors.

Material | Microstructure | Sensitivity level (kpl) | Range (ka) | Response time (mj) | Inspection and verification | Ref |

ZnOEP/CNT/PDMS | cobweb | 39.4 | 10.0 | 3 | 5000 | [22] |

rGO/FW | Wood surface | 1. 85 (<60 kPa) | 120.0 | 150 | 10000 | [23] |

AgNWs/Paper | 1.5 | 30.2 | 90 | — | [24] | |

NCB/PDMS | multiaperture | 31.63 (< 2 kPa) | 15.0 | 15 | — | [6] |

CNT/PDMS sponge | multiaperture | 0.01 | 1200.0 | 8.5 | 10000 | [5] |

Graphene /PDMS | finger print | 110 (< 0.2 kPa) | 75.0 | 30 | 10000 | [25] |

Cu /Cr/PI | 24. 2482 (>30.84 kPa) | — | 18 | — | [26] | |

FEDOT 、PSS/PDMS | abrasive paper | 851 (<3 kPa) | 20.0 | 0.15 | 18000 | [27] |

MCNTs/PDMS | pyramid | -2.65 (<0.3 kPa) | 3.5 | 80 | 100 | [28] |

Table 2. Overview of merits and shortcomings of various pressure sensors.

Type | Merit | Shortcoming |

Piezoresistive sensor | The relative cost is low Easy signal detection Easy to understand structure Wide sensing range | Stability is easily affected The sensitivity is relatively low poor precision Excessive power usage |

Capacitive sensor | high sensitivity fast response Good durability Wide operating range | Complex manufacturing process The inter-sensing unit crosstalk Susceptible to environmental influences |

Piezoelectric sensor | high sensitivity fast response Wide dynamic response range Lower power consumption | Requirement for active circuit Higher cost The variety of materials chosen is limited. |

Triboelectric sensor | lightweight easy manufacture high sensitivity self-powered properties. Contact-free sensing A wide selection of materials | muting sensitivity Low precision lack of stability It is very easily affected by the humidity |

Figure 5. Potential Uses of Flexible Sensors, and Various Materials and Constructions for Creating Flexible Sensors [7].

5. Discussion

This paper has comprehensively covered the concept and applications of flexible pressure sensors. It presented the principles and advantages of various new flexible pressure sensors by analyzing different materials and structural designs. Notably, these sensors offer advantages such as low cost, simple structure design, fast response, and wide dynamic range. Various preparation methods like cascade, self-assembly, and template methods were discussed, simplifying and enhancing the flexibility of the sensor preparation process. The paper also explored the potential uses of flexible pressure sensors in diverse industries, including medical health monitoring, wearable electronics, and human-computer interaction as shown in Table 3. Given their excellent performance and flexibility, flexible pressure sensors are well-suited for these applications.

Table 3. Application Prospects of Flexible Pressure Sensors.

Application prospect | Specific application |

Wearable human-computer interaction | Intelligent recognition (image, voice, gesture, face) Intelligent interaction Haptic feedback |

Health monitoring | Wearable medical devices Physiological signal monitoring Posture and activity monitoring |

Medical application | Intraoperative pressure monitoring Gastrointestinal dynamics Patient posture monitoring |

Human-computer interaction | Robot touch sensing Gesture control |

Industrial application | Industrial automation Robotic pressure monitoring |

Environmental monitoring | Soil pressure Atmospheric pressure Water gas fluid pressure |

The research concludes that there is ample room for innovation and improvement in the design and manufacturing technology of flexible pressure sensors. One area of improvement could be the optimization of microstructures to enhance performance indicators. Additionally, the organic combination of different microstructures will be a development direction, synthesizing the advantages of various structures to achieve better sensing performance. Furthermore, flexible pressure sensors will evolve into multifunctional devices with adaptability for various scenarios, extending their application to a wider range of fields, such as wearable devices, medical monitoring, and industrial automation. Advanced manufacturing techniques will contribute to achieving greater performance, stability, and sustainability for flexible pressure sensors. In summary, flexible pressure sensors are currently in a rapid development stage, and through structural optimization, function expansion, and innovation in manufacturing technology, their application prospects are broad.

6. Conclusion

This paper thoroughly explored the working principle, composition, and potential applications of flexible pressure sensors, focusing on their stretchability, flexibility, and sensing capabilities. The research demonstrates that combining different materials and structures can lead to high sensitivity, low cost, and fast response, thereby enhancing the sensor’s overall performance. Specifically, flexible capacitive pressure sensors exhibit excellent flexibility and rapid response, flexible piezoresistive pressure sensors offer a broad measurement range and outstanding sensitivity, while flexible piezoelectric pressure sensors have a straightforward design and long lifespan. According to performance analysis, capacitive sensors are particularly suited for usage in the field of electronic skin, while piezoresistive sensors are more frequently employed for sports and health monitoring to track people’s behavior. As a result, Flexible pressure sensors come in a variety of materials and designs, and since they perform and adapt to their surroundings differently, it is important to select the right sensor type for the job. Moreover, a detailed analysis of the materials and structures of various sensor types provides valuable insights and guidance for future research and applications.

The advancements and applications of flexible pressure sensors have been outlined, and their potential for the future has been discussed. However, flexible pressure sensors still face several technological difficulties and constraints, like environmental stability issues, exposure to outside interference, and greater prices. Moving forward, sensor research should prioritize increasing sensitivity, diversity, and intelligence while expanding the scope of applications. With continuous efforts in optimizing designs and exploring new materials, flexible pressure sensors are expected to play an increasingly significant role in various industries, paving the way for innovative and versatile sensing technologies.