1. Introduction

Temperature, as a crucial physical quantity, plays an indispensable role in human production, life, and scientific research. In the past, various methods were employed to measure temperature. However, the development of temperature sensors has provided more accurate and flexible temperature measurement solutions. This paper traces the historical development of temperature sensors and explores their practical applications in different temperature environments, with a particular focus on high, low, and ambient temperature conditions. Additionally, the characteristics of the LM35, DS18B20, and DHT22 sensors are detailed, and their strengths and limitations are analyzed. Through this exploration, the author aims to enhance readers’ understanding of the importance and applications of temperature sensors in different fields.

2. Historical Origin

In ancient times, people used basic physical phenomena to sense temperature changes, such as touching objects to feel their temperature. Ancient Greek and Indian civilizations employed changes in the volume of water or oil to detect temperature variations. This principle was applied to the development of the thermocouple, a commonly used temperature sensor. With the progression of semiconductor technology, temperature sensors based on semiconductor materials emerged.

Today, propelled by scientific and technological advancements, various types of temperature sensors continue to emerge. These include thermistors, thermocouples, infrared sensors, and more. Modern temperature sensors find extensive use in industrial, medical, aerospace, and environmental monitoring applications, delivering precise and dependable temperature measurements for a wide array of scenarios.

3. Temperature environments

3.1. Temperature from 100°C to 1000°C

Fiber Optic Temperature Sensors (FOTS) are devices that utilize optics to measure temperature changes. These sensors are based on the optical properties of optical fibers and typically employ either Fiber Bragg Grating (FBG) within the fiber or the optical properties of the fiber itself to gauge temperature. A FBG is a periodically modulated section of an optical fiber that reflects light as it passes through, and its wavelength shifts in response to temperature changes. This enables the determination of temperature fluctuations by measuring alterations in wavelength. These sensors transmit optical signals via optical fibers and ascertain temperature changes by analyzing the shifts in the optical signal. Fiber optic temperature sensors offer numerous advantages, including high accuracy, immunity to electromagnetic interference, and suitability for challenging environments, which has led to their wide utilization across various applications. They employ the optical properties of optical fibers to detect temperature changes and are well-suited for high-temperature environments, areas with strong electromagnetic interference, and hazardous conditions.

Contemporary research predominantly explores the benefits of fiber-optic temperature sensors in temperature detection. It also reviews the current development status and applications of these sensors. The text delves into the working principles and research progress of various types of fiber-optic temperature sensors, including distributed optical fiber temperature sensors, optical fiber grating temperature sensors, interferometric optical fiber temperature sensors, optical fiber fluorescence temperature sensors, and optical fiber temperature sensors based on bending loss. The distinct characteristics of each sensor type and their respective research directions are discussed in detail [1]. Additionally, the text addresses the application of optical fiber temperature sensors in the electric power system, highlighting challenges and shortcomings and proposing corresponding solutions, along with an outlook on their future prospects [2].

3.2. Temperature from -40°C to -80°C

The low-temperature environment offers a novel research setting for comprehending the uncharted realms, such as superconductivity technology and fundamental physics. Low Temperature Temperature Sensors with low-temperature measurement range have been employed to gauge phenomena like heat waves in superfluid helium and temperature shifts during secondary phase transitions in superfluid helium [3]. Temperature sensors designed for low-temperature conditions require attributes such as high precision, stability, low-temperature resilience, and immunity to interference. These features are essential to ensure accurate temperature measurements in such environments. Different types of cryogenic sensors are chosen and optimized to suit specific applications. Common temperature sensors used in low-temperature settings encompass magnetic temperature sensors, platinum resistance temperature sensors, thin film temperature sensors, and superconducting temperature sensors. Temperature measurement is a recurrent facet within the cryogenic research field.

In recent times, several countries, particularly developed ones, have made strides in the development of low-temperature temperature sensors and their applications. This text introduces these advancements and scrutinizes the prospective trends in temperature sensor evolution. It also highlights the disparities between China and other nations in this domain [4].

3.3. Temperature from 20°C to 30°C

As time progresses, temperature sensors continue to advance, and the following highlights some of the latest trends and technologies in temperature sensor technology: flexible temperature sensors, wireless temperature sensors, wearable temperature sensors, and multi-point temperature sensors, among others. Let’s take wireless temperature sensors as an example. Numerous scientific research projects have presented outcomes based on the microcontroller PIC16C74, the digital temperature sensor DS18B20, and the monolithic RF transceiver chip nRF2401 for creating digital wireless temperature sensors. These sensors offer a temperature measurement range of -40 to 95 ℃, a resolution of 0.0625 ℃, and operate within a frequency range of 2,400 to 2,524 MHz. They exhibit a receive sensitivity of -90 dBm, a maximum transmitting power of 0 dBm, and are powered by batteries [5].

Presently, the evolution of temperature sensors is rapidly progressing towards heightened accuracy, broader applications, reduced size, lower power consumption, enhanced multifunctionality, and increased intelligence. The influence of micro-nanotechnology has led to the miniaturization of temperature sensors, enabling precise temperature measurement within confined spaces. Nanomaterials and nanostructures are also playing a role in developing highly sensitive temperature sensors. Digitization and intelligence are becoming integral to temperature sensors, with digital variants witnessing widespread adoption. When coupled with modern data processing techniques, these sensors offer enhanced precision in temperature measurement and facilitate remote monitoring and control.

A new generation of temperature sensors often boasts multifunctional capabilities, extending beyond temperature measurement to include humidity, pressure, gas composition, and other parameters. This makes for more comprehensive environmental monitoring. Wireless communication technology’s progress permits real-time data transmission and monitoring, a crucial aspect for remote monitoring, industrial automation, and Internet of Things applications.

Incorporating new materials further expands sensor performance. Special materials with distinct thermal conductivity and heat capacity properties contribute to heightened accuracy and responsiveness. Low-power designs enable temperature sensors to operate continuously on battery power, extending their lifespan, particularly in remote and mobile applications. Optical and photonic technologies, such as fiber optic temperature sensors and infrared temperature sensors, are gaining prominence, enabling non-contact temperature measurement.

Contemporary temperature sensor design increasingly prioritizes environmental friendliness and sustainability, incorporating low-energy materials and eco-friendly manufacturing processes to minimize environmental impact. Temperature sensors find application in diverse fields including industrial production, healthcare, energy management, agriculture, transportation, meteorology, and beyond. As technology advances, their application areas are set to expand further.

4. Specific model temperature sensors

4.1. LM35

The LM35 is a widely used integrated circuit temperature sensor designed for temperature measurement, manufactured by Texas Instruments. It finds application in various fields including industrial, medical, environmental monitoring, and automation control. Based on integrated circuit technology, the LM35 utilizes the temperature characteristics of semiconductor materials to accurately measure temperature. Internally, it incorporates a temperature-sensitive resistor. As temperature changes, the resistor value undergoes corresponding changes. The LM35 converts temperature into a voltage signal, establishing a linear relationship between output voltage and Celsius temperature. Its high accuracy in temperature measurement is notable, with typical precision achievable to about ±0.5 degrees Celsius. The LM35 operates within a range of -55 to 150 degrees Celsius, rendering it suitable for diverse environments. Its low power consumption makes it ideal for battery-powered applications. With a typical output voltage range of 0V to 1V, the LM35 can be directly connected to analog input pins, eliminating the need for complex calibrations. The LM35 temperature sensor finds use across a wide spectrum of applications, including but not limited to:

- Measuring indoor and outdoor temperatures, including weather stations.

- Temperature measurement in industrial processes for control and monitoring.

- Integration into medical equipment such as thermometers.

- Monitoring and control of automotive interior temperatures.

- Temperature regulation in household appliances like refrigerators and air conditioners.

- Usage in rapid prototyping for temperature measurement experiments.

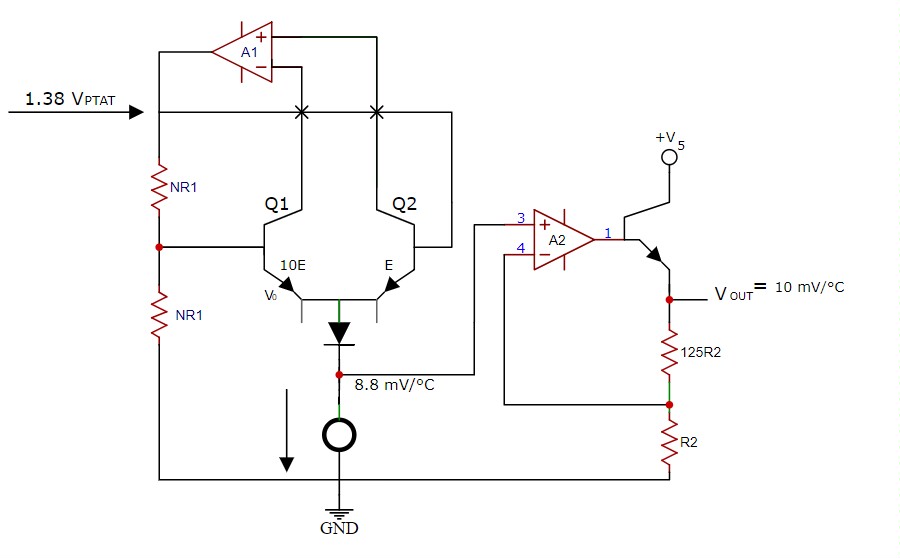

Although the LM35 offers high accuracy, calibration might be required in specific applications for precision. Due to its narrow output voltage range, an amplifier or analog-to-digital converter could be needed to extend the range or digitize the output. Overall, the LM35 temperature sensor furnishes a dependable temperature monitoring solution for diverse applications, serving as a widely adopted and user-friendly temperature measurement device. Figure 1 shows the circuit of LM35.

Figure 1. Circuit of LM35.

The system measures temperature using LM35 and adjusts the fan speed based on programmed settings. The LM35 temperature sensor is employed to detect the surrounding temperature. It generates a voltage of 10mV for every 1°C increase in temperature. The temperature sensor’s output, in the form of an analog signal, is directed to the input of the Analog-to-Digital Converter (ADC). This ADC converts the analog temperature value into the digital equivalent required by the microcontroller. Subsequently, the ADC’s output is directly linked to the microcontroller, which is responsible for regulating the fan speed through actuators [6]. Accuracy stands out as a pivotal factor when innovating or creating a new product. In our project, achieving a high level of accuracy was paramount to developing a quality product. Our objective was to measure temperature with the highest degree of precision possible.

4.2. DS18B20

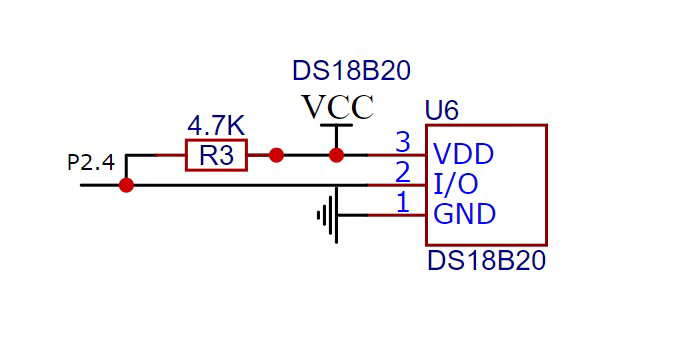

The DS18B20, produced by Maxim Integrated, stands as a prevalent digital temperature sensor extensively employed across diverse temperature measurement scenarios. It is favoured for its high accuracy, digital output, single bus communication protocol and adaptability. The DS18B20 is based on the digital temperature sensing principle and has an internal integrated temperature sensor, analogue-to-digital converter and serial digital interface. The temperature sensor element inside the sensor will generate a voltage signal according to the temperature change, which will be converted into a digital signal by the analogue-to-digital converter, and then output through the serial digital interface.DS18B20 usually has a high temperature measurement accuracy, which can reach about ±0.5 degree Celsius or even higher.DS18B20 outputs a digital signal through a single bus communication protocol, which is free from the interference of analogue signals, and is easy to be DS18B20 is suitable for the measurement of temperature range from -55 degree Celsius to +125 degree Celsius.DS18B20 uses one bus to communicate, only one GPIO pin is needed, which is convenient to connect multiple sensors to build a sensing network. The resolution of DS18B20 can be programmed and adjusted according to the application requirements, ranging from 9 to 12 bits, the higher the resolution, the higher the accuracy.DS18B20 can be adjusted according to the application requirements, ranging from 9 to 12 bits, the higher the resolution, the higher the accuracy. The higher the resolution, the higher the accuracy.DS18B20 is suitable for a variety of application environments, including humidity, vibration and other harsh conditions.DS18B20 temperature sensors are widely used in a variety of fields for industrial process monitoring and control, such as temperature regulation and alarm. For indoor and outdoor temperature monitoring, weather stations, etc. For temperature monitoring in medical equipment, e.g., thermometers. Used for temperature monitoring in electronic equipment, e.g., computers, servers, etc. Used in smart home systems to control temperature and energy consumption. DS18B20 requires an additional power supply when in use, usually 3V to 5V. In a multi-sensor network, attention needs to be paid to the electrical characteristics of the bus and the connection method to avoid communication conflicts. Overall, the DS18B20, as a high-precision digital temperature sensor, has a wide range of applications in temperature measurement applications, especially in scenarios that require multi-sensor networks, high precision and digital output. Figure 2 shows the circuit of DS18B20.

Figure 2. Circuit of DS18B20.

The DS18B20 temperature sensor is a digital temperature sensor that has a wide range of applications in various fields. In the industrial field, the DS18B20 sensor is commonly used to monitor the temperature of production equipment to ensure process stability and product quality. In the medical field, it can be used to monitor the temperature of medical equipment, such as drug storage and blood delivery, to ensure the safety and effectiveness of medical operations. In environmental monitoring, DS18B20 sensors can be used to measure atmospheric temperature to provide data support for weather forecasting and environmental protection. In addition, it also has an important role in agriculture and food processing, monitoring soil temperature, food storage temperature, etc., to ensure crop growth and food quality. Due to its digital output and high accuracy, DS18B20 sensors are able to provide accurate and reliable temperature data in a variety of applications, providing important technical support for monitoring and control in a variety of industries [7].

4.3. DHT22

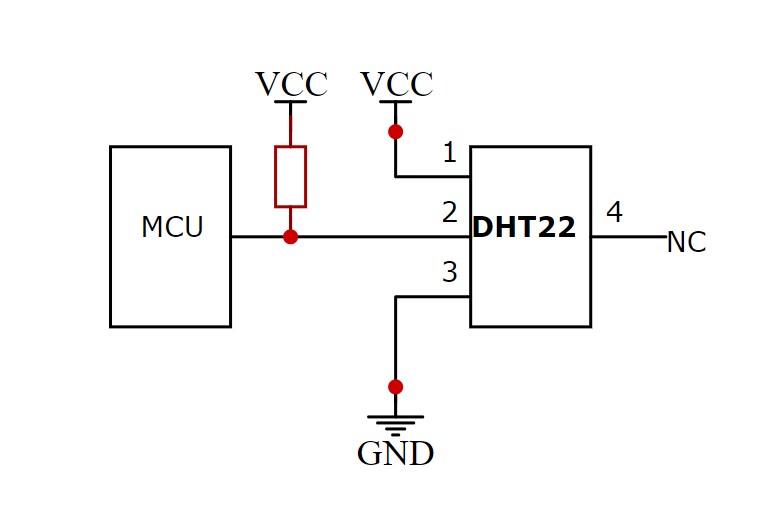

DHT22, also known as AM2302, is a digital temperature and humidity sensor manufactured by Aosong (Guangzhou Aosong Electronics Co.). It is widely used in a variety of environmental monitoring and control applications due to its high accuracy, digital output, and simultaneous measurement of temperature and humidity. The DHT22 is based on the principle of digital temperature and humidity sensing, and integrates temperature and humidity sensor elements, as well as an analogue-to-digital converter and a digital signal output circuit. The sensor element generates electrical signals according to the temperature and humidity changes in the environment, which are converted into digital signals by the analogue-to-digital converter and then output through the digital signal output pins. The DHT22 usually has a high temperature and humidity measurement accuracy, with a temperature accuracy of about ±0.5 degrees Celsius and a humidity accuracy of about ±2% RH. The DHT22 outputs the temperature and humidity values digitally, which is free from interference with analogue signals, and is easy to read and process. The DHT22 can also output the temperature and humidity values digitally, so it is not subject to interference with analogue signals. The DHT22 can measure ambient temperature and humidity simultaneously, providing real-time environmental information. The DHT22 is suitable for temperatures from -40 degrees Celsius to 80 degrees Celsius, and humidity from 0%RH to 100%RH. The DHT22’s low power consumption makes it suitable for use in battery-powered equipment. The DHT22’s fast response time provides accurate temperature and humidity readings in a short period of time. The DHT22 temperature and humidity sensors have been designed for use in a variety of applications. The DHT22 temperature and humidity sensor is widely used in a variety of applications for indoor and outdoor temperature and humidity monitoring, weather stations, and more. Used in agriculture to monitor soil moisture and climatic conditions. For temperature and humidity control in greenhouses to improve plant growth efficiency. Used for temperature and humidity monitoring of electronic equipment, such as server room. Used in smart home systems to control indoor temperature and humidity and air conditioning, etc. The DHT22 is normally supplied with a supply voltage of 3V to 5V, and needs to be used at a suitable supply voltage. Periodic calibration may be required to ensure accuracy of measurements during extended use. Overall, the DHT22 temperature and humidity sensor is suitable for a wide range of environmental monitoring and control applications as a digital sensor that simultaneously measures temperature and humidity with high accuracy and stability. Figure 3 shows the circuit of DHT22.

Figure 3. Circuit of DHT22.

The acquisition of boiling temperature necessitates immersing both sensors in boiling water. As the sensors lack waterproofing, a minor adjustment was implemented in the experiment. Instead of submersion, both sensors were affixed to the kettle. Given that the probe exclusively gauges the metallic kettle’s surface, a recording of 100°C by the sensors isn’t anticipated. Notably, the highest registered temperature reached 90°C, aligning with the kettle’s automatic shutdown upon boiling. Conversely, the DHT22 sensor solely documented temperatures up to 40°C, significantly divergent from the thermocouple’s 90°C boiling point measurement. Evidently, the 6517-TP exhibited an ascending temperature trend as the water reached boiling point. In contrast, the DHT22 exhibited a relatively sluggish temperature ascent compared to the Keithley probe [8].

5. Results

The LM35 sensor, as an analogue output sensor, is simple and easy to use and is widely used in room temperature monitoring and weather stations in room temperature environments. However, due to the interference of its analogue output, its accuracy is relatively low and may not perform well in high-precision applications.DS18B20 sensors, known for their digital output and high accuracy, are suitable for scenarios requiring accurate temperature measurement, such as precision instruments and medical equipment, and perform well especially in low-temperature environments. However, it may have some measurement uncertainty under extreme conditions and is relatively expensive compared to other sensors. The DHT22 sensor measures not only temperature but also humidity, making it suitable for indoor temperature and humidity monitoring, agricultural environments, and more. However, its humidity measurement may be affected by temperature, resulting in data accuracy in some application scenarios to be further verified.

6. Conclusions

Temperature sensors play a key role in the development of human society, and constantly innovative technologies have made temperature measurement more accurate and flexible. This paper provides an in-depth discussion of the history, applications, and technological trends of temperature sensors, as well as demonstrating their strengths and limitations in different environments through examples of three sensors: the LM35, DS18B20, and DHT22. These sensors are widely used in industrial, medical and agricultural fields, providing reliable temperature data support for various industries. With further innovations in technology, the author can expect temperature sensors to play more important roles in the future, promoting the development and progress of various fields.