1. Introduction

At present, with the improvement of people’s living standards and the rapid development of e-commerce, the volume of express delivery is increasing. The existing manual sorting method is high-cost and low-efficiency, and the sorting efficiency cannot reach the transportation efficiency, resulting in frequent accumulation of express delivery at the site. An efficient domestic waste sorting method is urgently needed by society. With the continuous development of mechanical arm technology and industry, the types and functions of mechanical arms are becoming more and more abundant. Using mechanical arms to replace manual work to complete express sorting tasks has advantages such as high efficiency and labor saving, which can save labor costs by nearly 51.73% [1]. The existing mechanical arms are widely used on the assembly line, and there is much literature. But at present, express sorting is mainly manual, and there are few kinds of literature on applying mechanical arms to express sorting field. Mechanical arms are mainly divided into articulated robot and parallel manipulator, which have different advantages and disadvantages. Mechanical arms can be set according to the characteristics of actual application scenarios, thereby improving work efficiency. In summary, this paper analyzes the application and development of different types of mechanical arms in express sorting system. First, the current situation of express sorting and the development of mechanical arm are introduced in detail in Chapter 2. Second, based on the structural characteristics, mechanical arms are divided into serial mechanical arms and parallel mechanical arms in Chapter 3. At the same time, the characteristics of the two kinds of mechanical arms are analyzed. Then, in Chapter 4, by comparing the advantages and limitations of different mechanical arms in express sorting field, their application prospects are predicted. Finally, Chapter 5 summarizes the whole paper.

2. Case description

2.1. Current situation and significance of express sorting

Express sorting is a process of stacking items according to their destination, order of entry, and exit. At present, with the improvement of people’s living standards and the rapid development of e-commerce, the volume of express delivery is increasing, and the timeliness requirements are also higher and higher, and the pressure of sorting is also increasing. At present, sorting relies on manual sorting under the assembly line. The increase in labor costs and the price reduction of express delivery lead to a shortage of sorting labor force. When there are too many express deliveries during holidays, the sorting efficiency can not reach the transportation efficiency, and express delivery will accumulate. And there are also dangers in sorting, such as workers being stuck by conveyor belts or being injured by unknown dangerous goods in express delivery. Based on high-precision sensors and actuators, intelligent mechanical arm can work efficiently for 24 hours without interruption, thus reducing workers’ risks while improving work efficiency. Therefore, the application of mechanical arm in express sorting is very meaningful.

2.2. Development status of mechanical arm

Mechanical arm is an important part of automatic industrial system, which has a broad application prospect in service, exploration, automation and other fields [2]. Mechanical arm consists of movable links that drive mechanical claws. Through kinematic design, mechanical arm can extend end effector to a specific position to grab and move objects. Therefore, combined with conveyor belt and vision recognition technology, mechanical arm can play a great role in object sorting work on assembly line. With the progress of science and technology, there are also many different branches of mechanical arm. Mechanical arm mainly includes Articulated robot, Parallel manipulator etc. Different types of mechanical arm have different performance, such as degree of freedom, accuracy, load capacity, and speed. Therefore, it is necessary to choose the appropriate type of mechanical arm to achieve the maximum efficiency when sorting different objects.

3. Case description

3.1. Articulated robot

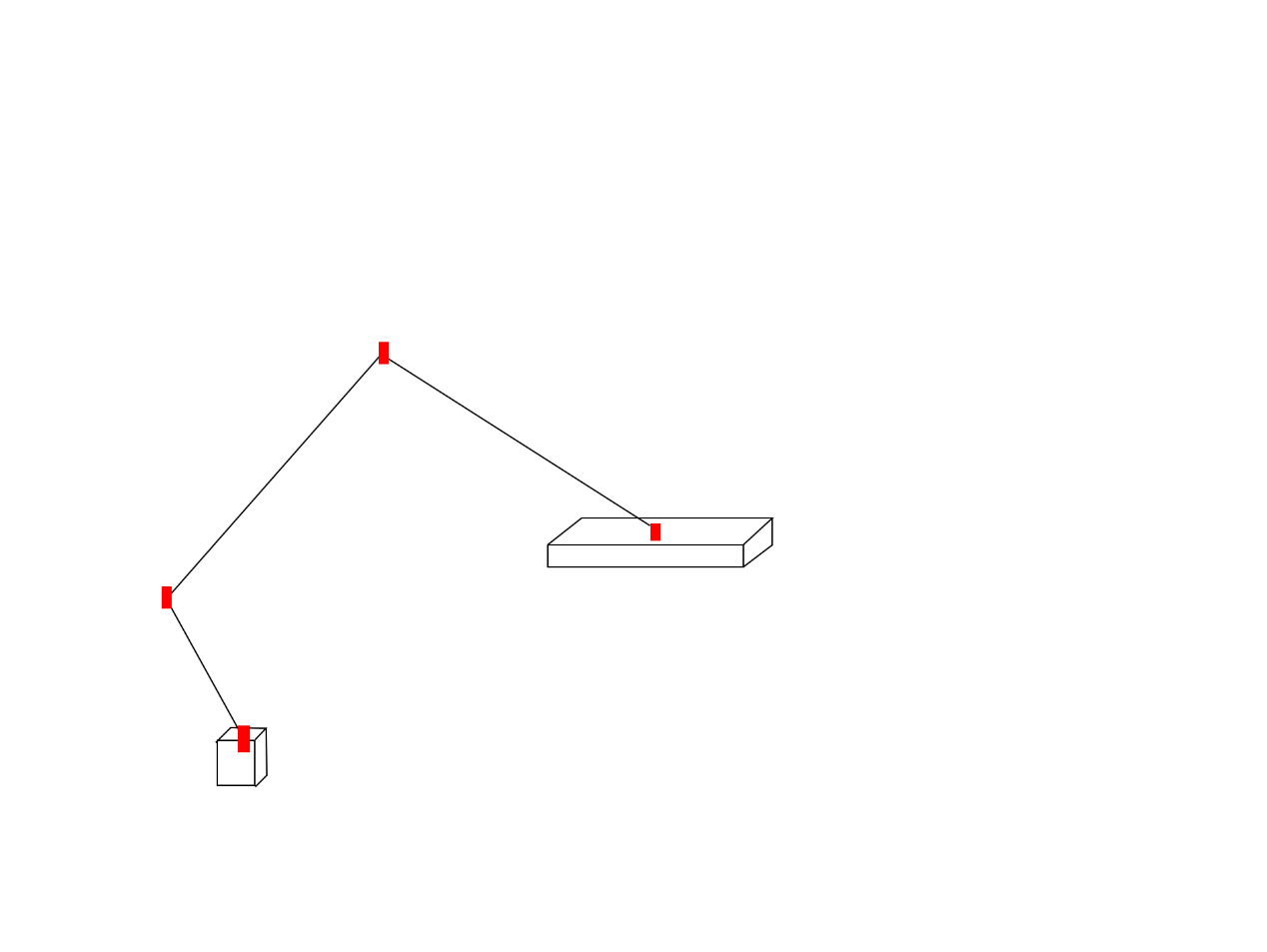

Articulated Robot is the most widely used type of industrial robot. It belongs to open-chain robot, which consists of links, joints, and end effectors. It looks like a human arm. If a cube represents a static platform, a cuboid represents a dynamic platform, a line segment represents a link, and a red block represents a driving joint, its structural diagram is shown in Figure 1. It realizes motion by rotating and translating each joint, which can make the mechanical arm realize various motion trajectories and postures in three-dimensional space. It combines the mechanical claw on the dynamic platform to complete the loading and unloading and moving tasks [3].

|

Figure 1. Structural diagram of articulated robot. |

3.1.1. Principle introduction. Articulated Robot is the most widely used type of industrial robot. It belongs to open-chain robot, which consists of links, joints, and end effectors. It looks like a human arm. If a cube represents a static platform, a cuboid represents a dynamic platform, a line segment represents a link, and a red block represents a driving joint, its structural diagram is shown in Figure 1. It realizes motion by rotating and translating each joint, which can make the mechanical arm realize various motion trajectories and postures in three-dimensional space. It combines the mechanical claw on the dynamic platform to complete the loading and unloading and moving tasks [3].

3.1.2. Advantages and limitations analysis for express sorting. The Kutzbach-Grubler formula is a general formula for calculating the degrees of freedom [4], which can be expressed as:

\( F=6(n-j-1)+\sum _{i=1}^{j}{f_{i}} \) | (1) |

, where \( n \) represents the number of links, j represents the number of kinematic pairs, and \( {f_{i}} \) represents the number of degrees of freedom brought by the i-th kinematic pair.

Multi-joint robot has some advantages in express sorting field. According to formula (1), the more joints of multi-joint robot, the higher degree of freedom. And the number of joints and links can be designed according to the needs. Therefore, multi-joint mechanical arm can have high degree of freedom. High flexibility makes it widely used in sorting field. Compared with other types of mechanical arm, it occupies less area and is easier to place on the sorting assembly line. But there are also some problems with multi-joint robot in logistics sorting field. Its motion depends on the coordinated motion of each joint, so the motor is located in the motion structure, and the motor often contains heavy rotors and magnets, which makes it heavy, resulting in large inertia and the need for reducer. And the heavy motor in the motion structure also makes it have limited extra load capacity when picking up things. And its forward kinematics analysis is easy, but inverse kinematics analysis is complex.

In summary, most of the existing sorting robots are serial mechanical arms, which are easy to design and apply in express sorting field due to their small footprint and other characteristics. It is easy to place on the express sorting line. It has high degree of freedom so it can sort objects on a single sorting line into multiple categories. But its heavy weight makes it have limited extra load capacity and can not cope with large packages.

3.2. Parallel manipulator

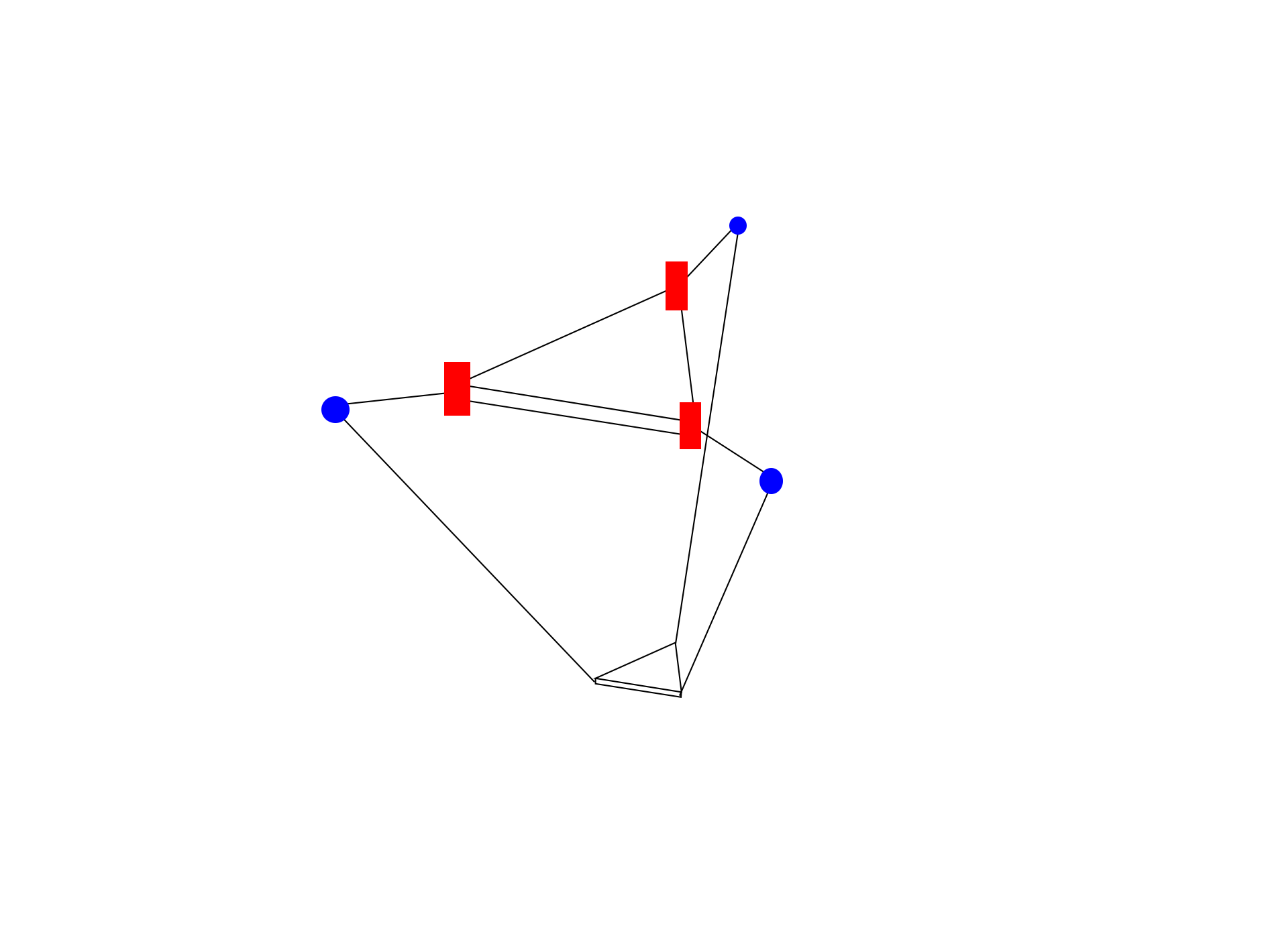

3.2.1. Principle introduction. Parallel manipulator is connected by at least two independent motion chains between fixed platform (upper platform) and dynamic platform (lower platform), and end effector is located on dynamic platform. The mainstream parallel manipulator is Delta robot, which was invented by Reymond Clavel’s research team in 1987 [5]. Delta means that both its base platform and motion platform are triangular in shape, as shown in Figure 2, with red blocks representing motors, blue balls representing joints, and line segments representing links. Delta robot is driven by three motors on static platform to drive three main arms, which drive three slave arms, which drive its dynamic platform [6].

|

Figure 2. Structural diagram of Delta parallel manipulator. |

3.2.2. Advantages and limitations analysis for express sorting. Parallel manipulator has many advantages in express sorting field. Its driving motor is located on static platform, symmetric position has equivalent performance and same model, so it has good isotropy and is easy to product design and drive. The multi-joint connection restriction of parallel manipulator increases its overall stiffness and stability. And the motor is located on static platform frame, not in motion structure, does not occupy load capacity, so the robot has stronger load capacity in express sorting. And without motor weight, its end can get very high speed and acceleration [7]. Parallel manipulator has the characteristics of fast movement speed, accurate positioning, low cost and high efficiency. Especially in vertical direction, it has high flexibility [8], so it is suitable for sorting heavier express delivery. But there are also some drawbacks to using parallel mechanical arms for express sorting. Because parallel mechanical arm has high nonlinearity, it is difficult to control [9]. Its inverse kinematics analysis is easy, but forward kinematics analysis is complex. The multi-joint restriction of parallel mechanical arm improves its stability and load capacity but reduces its degree of freedom compared with serial mechanical arm, and the motion platform cannot rotate around any axis.

In general, compared with articulated robot, parallel manipulator have several advantages: they can achieve high speed and acceleration, they have large effective payload capacity, and large effective payload-stiffness ratio [10]. Therefore, parallel mechanical arm has great advantage in grasping heavier objects on assembly line, and can sort heavier express delivery. But its degree of freedom is not as good as serial mechanical arm, facing express delivery from different regions on conveyor belt, it can not sort too many categories.

3.3. Comprehensive application analysis

Because Articulated Robot occupies small area, has a high degree of freedom and low load capacity, it is suitable for sorting small, wide-area express delivery. Because parallel manipulator has large load capacity and low degree of freedom, it is suitable for sorting heavy and few-area express delivery.

Facing the express delivery of different sizes and addresses on the conveyor belt, a single type of mechanical arm cannot complete the sorting efficiently. And at present, industrial robot that can meet the requirements of large load, high precision and high degree of freedom has high cost, which is not suitable for large-scale layout in express sorting industry. However, the use of multi-robot control can reduce the operation cost in industry [11], so different types of mechanical arms can be combined to work together. Articulated robot can sort small, wide-area express delivery, and parallel manipulator can sort heavy and few-area express delivery, thus completing the express sorting on the conveyor belt with high efficiency and low cost. At the same time, when robot groups work on large production lines, how to allocate tasks among robots is also very important [11], so industrial Internet of Things and computer vision recognition can be combined to intelligently identify the volume, weight and destination of express delivery, and intelligently select the optimal mechanical arm to make the sorting link efficient.

4. Conclusion

This paper analyzes the application and development of different types of robotic arms in express sorting systems. It introduces the principles, advantages and limitations of Articulated Robot and Parallel manipulator, and compares their suitability and prospects in express sorting fields. In view of the problem that a single type of robotic arm cannot efficiently complete the express sorting task, it proposes that different types of robotic arms should be combined, and intelligent selection and collaboration should be made according to the quality and destination of express delivery. It also proposes that the express sorting system based on robotic arm can be combined with industrial Internet of Things and computer vision recognition to improve the efficiency of sorting link. This paper provides some references and inspirations for the application of robotic arm in express sorting system.