1. Introduction

The industry chain of personalized customization of 3D prostheses has now realized the two keywords of precision and efficiency. High-precision data is obtained through computer scanning to print the modeling material of the prosthesis, ensuring that the prosthesis can fit perfectly with the patient’s injury and reduce the pain of the patient. Through the complete solution of the whole chain, the process of medical interaction is standardized, the communication between engineers and doctors is more convenient and effective, and reasonable surgical methods are formulated to meet the needs of different orthopaedic patients with personalized implants, and the clinical needs of doctors are quickly and accurately transformed into products [1]. The gradual improvement of the industrial chain has reduced the cost of customization to a certain extent, but in fact, the price of prostheses customized using 3D modeling and printing technology is still high. This article will review the literature, combined with their own thinking, put forward views and suggestions for this problem.

This paper uses the method of literature review to read, quote and summarize the experimental records and opinions of several domestic and foreign professionals, focusing on the history of 3D modeling and printing technology (the source and development of modeling, the change of materials used), the application method of this technology (the use of instrument software, The method of scanning and modeling) and the current clinical application of 3D modeling printing technology (in medicine and medical beauty).

This study collects and summarizes part of the information, provides some reference suggestions for the field of 3D modeling printing, and contributes to the research in this field to a certain extent.

2. 3D modeling and printing technology

3D printing technology emerged in the 1980s, developed from rapid prototyping technology, also known as Additive Manufacturing (AM) technology [2]. It is a digital model file based on the use of powder metal or plastic and other adhesive materials, the use of light curing and paper lamination technology, through the way of printing layer by layer to construct the object of rapid prototyping device [3]. It works basically the same as the ordinary printer, the printer is equipped with liquid or powder and other “printing materials”, connected with the computer, through the computer control the “printing materials” layer by layer superposition, and finally the blueprint on the computer into a physical object.

The technology used to be used in art, industrial design and other fields to make models, and is now gradually being used in the direct manufacture of some products. The technology is now used in a variety of fields, and some high-value applications (such as hip joints or teeth, or some aircraft parts) already have parts printed using this technology.

The most outstanding advantage of 3D modeling and printing technology is that parts of any shape can be generated directly from computer graphics data without mechanical processing or any mold, which greatly shortens the development cycle of products, improves productivity and reduces production costs. At the same time, 3D modeling and printing technology reduces the cost by abandoning the production line and greatly reduces the waste of materials. Moreover, the combination of computer and printer enables it to produce shapes that cannot be produced by traditional production technology, greatly improving the efficiency of production.

2.1. Application method of 3D modeling

The application field of 3D modeling printing technology is expanding with the progress of technology. People have used this technology to print out lamp shades, body organs, jewelry, football boots customized according to the players’ feet, racing parts, solid-state batteries, mobile phones and violins customized for individuals, etc. Some people even use this technology to manufacture mechanical equipment. Furthermore, 3D printing technology is unique in the medical field with its flexible personalized customization features and has a great space for development. From a medical point of view, 3D printing technology has personalization, local production, unlimited number, and section [4].

The characteristics of approximate cost can just meet the needs of personalized and precision medicine.

2.2. The source and development of modeling

The roots of 3D modeling go back to the 1960s. 3D modeling was a restricted field in that era, and only technical and robotics professionals had access to tools that dealt with statistical equations. 3D modeling emerged and showed promise in that era, but limited access to modeling systems as well as the high cost of materials kept it from making a splash in society at the time. Modeling at the time was extremely difficult and relied entirely on mathematical models.

In the 1970s, A. Sutherland invented and developed Sketchpad, the first 3D modeling and generation technology, which sparked A movement among designers and writers. Soon after, Ed Catmull built a curved, accurate version of the forearm in basic 3D modeling tools, bringing realism to visualizations, a texture-mapping technique essential for presenting the form of a bicubic surface.

The 1980s were the era when 3D modeling became one of the most popular programs. The mutually beneficial relationship between software businesses and their customers helped develop sophisticated techniques that could perform complex calculations and quickly generate models.

1990s Autodesk introduced the first 3d Workshop in 1990 and ray tracing is used for visualization in Autodesk’s 3D modeling and modeling products.

After the 2000s, 3D modeling technology moved in a positive direction, with more and more software packages becoming accessible. Thanks to cloud services, software products are now transitioning to cloud-based platforms where anyone can access documents and identities anywhere in the globe and on any system (computer, laptop, workstation, tablet, etc.) [5].

As the years change, 3D modeling technology continues to mature and gradually become available to the public.

2.3. Instruments and software used

The most basic configuration requirements are I5, more than 2G independent display and more than 8G memory, the general general configuration is I7, GTX1050T, 16G memory, 120G solid state drive, 1T mechanical disk, if you need to use the next generation of 3d modeling software on the computer configuration requirements will be higher.

There are two ways to build 3D model: one is to use SolidWorks, 3Dmax, AutoCAD and other 3D drawing software to build 3D data model; Alternatively, 3D scanners such as Polhemus, 3DCamega, or ZCorp can be used to scan the 3D data of the object to be obtained, and then the data can be digitally imported into a computer to generate a virtual model [6]. There are some information about different types of softwires:

SolidWorks: The most common industrial modeling software for computer-aided modeling and design.

Rhino: Parametric modeling for a wide range of applications, not limited to product design, jewelry design, architectural design, ship design, even multimedia and graphic design.

3Ds Max: Used in video game development, art field, architectural visualization, industrial design. With complex particle and light simulation, fabric simulation engine and script design, 3DS Max is an indispensable software in 3D modeling.

Maya: Maya is mainly used in film and television advertising, character animation, film special effects and other fields.

Autodesk Fusion 360: Powerful parametric tools and analytical web tools for industrial and architectural design.

2.4. How to scan and model

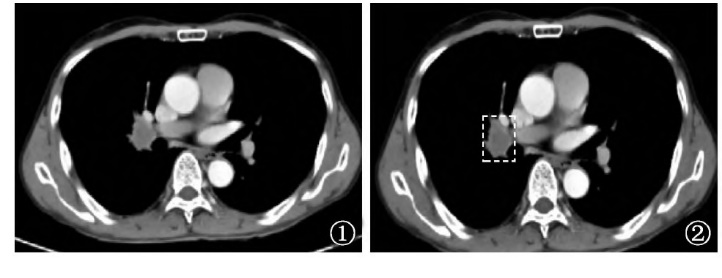

CT and X-ray scans were performed on the location of the patient’s lesion to meet the requirements of three-dimensional reconstruction of the patient’s location and the image data of the accuracy of the three-dimensional model. The technical parameters such as the patient’s body position, scan layer thickness and scan spacing should be considered in the collection process [7].

Figure 1. CT scan data of a patient’s body [8].

3. Modeling

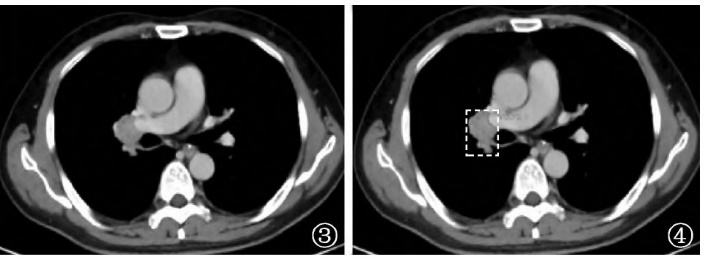

Reconstruct CT data as needed to build a 1:1 3D model. The software generally uses Mimics Innovation Suite to reconstruct the 3D model after importing the data. The processing of image data should consider the elimination of artifacts and noise [9]. Then the data is imported into the Mimics software, and according to the design requirements of the patient’s prosthesis, the CT Bone Segmentation instructions are used to quickly reconstruct the patient’s bone model.

Figure 2. A 3D model of Temporomandibular joint [10].

3.1. Application method of 3D printing

Generally, titanium alloy material is used as the raw material for the fabrication. Titanium alloy material has the properties of low density, high strength, good biocompatibility, and good corrosion resistance, and has been the preferred orthopedic implant processing material [11].

Table 2. Print raw material chemical composition [12].

Element | Al | V | C | Fe |

ASTM F3001 | 5.50-6.50 | 3.50-4.50 | ≤0.08 | ≤0.25 |

% | 6.47 | 4.12 | 0.01 | 0.22 |

O | N | H | Y | Ti |

≤0.13 | ≤0.05 | ≤0.012 | ≤0.005 | Bal. |

0.08 | 0.01 | 0.001 | <0.001 | Bal. |

3.2. How does the 3D printer operate and the structure of the 3D printed product.

3D printer is based on the digital model file, the use of powder metal or plastic and other adhesive materials, the use of light curing and paper lamination technology, by printing layer by layer to construct the object. Depending on the patient, data such as the Angle of the biomechanical characteristics of the joint surface need to be measured. Prosthesis products to minimize the friction of the articular surface, need to be processed, and its surface is highly polished, to establish a low friction interface, to achieve a perfect match with the patient.

At the same time, the prosthesis usually has a mesh structure, and the main purpose is to ensure that the bone cells grow in or over the postoperative.

4. Use 3D modeling and printing techniques to create the prosthesis

Due to the outstanding advantages of 3D printing -- it is good at building products with complex shapes and structures and individual customization, the explosive growth of its application in clinical medicine is also logical [12].

Although the cost of traditional skeleton prosthesis is low, it has great harm to the human body. Zhiqiang Liang, Zihan Yang et al. studied the effects of different knee prosthesis sizes and implant positions on the relative displacement of femur and tibia of knee after artificial knee replacement, using preoperative CT and MRI data of healthy subjects and patients with knee osteoarthritis to establish a finite element model. The participants’ gait parameters and ground reaction forces were collected, and the data were simultaneously collected by the 3D dynamic capture system and the 3D force measuring table. At the same time, artificial knee replacement was simulated, and the tibial prosthesis was moved 1mm in and out of the joint, and the relative displacements of the femur and tibia at the standing position, the first peak and the second peak of the ground reaction force at different prosthesis sizes and implantation positions were analyzed. It was found that the implantation of artificial knee joint would increase the displacement of femur and tibia [12]. Zhao Feng mentioned in his article that in the study of talus, the previously studied talus prosthesis has the following shortcomings: First, the prosthesis only plays the role of structural support and has no biological function; Second, due to the inconsistent processing requirements of each component, the prosthesis with biological function is not easy to manufacture, cannot meet the clinical needs in time and is expensive [13].

Customized prostheses can have a better effect during recovery. Zhao Feng conducted a return visit to the patients with 3D prosthesis implants, and used CT and other methods to observe whether the shape of the personalized prosthesis has changed and whether the properties such as tissue inductance and mechanical strength have reached the purpose of design and development. The patient’s functional recovery was good 2 years after surgery, the patient could walk, run and jump normally, the joint movement function met the requirements, and the function was significantly improved before and after the operation.

Compared with the traditional bone prosthesis, the prosthesis customized by 3D modeling and printing technology is significantly less harmful during implantation and postoperative recovery, and the design of porous structure gives the prosthesis biological function to a certain extent. At the same time, the customized prosthesis reduces the friction of the joint surface and has a longer life span.

5. Discussion

This study studied the history of 3D modeling printing, common software and operation methods through literature review, and compared the advantages and disadvantages of traditional prostheses and 3D custom prostheses.

The technology of 3D modeling and printing has been preliminarily accumulated in modern times, but it seems that it is temporarily unable to have a large-scale leap in the future for a short time. The extremely high cost and relatively long production time hinder the popularization of 3D prosthesis customization. At this stage, we can only increase the efficiency of production by establishing an industrial chain of medical and industrial cooperation to meet more needs. Industrialization of 3D printing equipment used in the production process, product production line planning, verification of production process; And to evaluate the safety, effectiveness, and controllability of personalized prostheses after implantation by testing the technical standards, preclinical biology and function of customized prostheses [14].

At the same time, the time of implantation of 3D customized prostheses in existing cases is too short, resulting in the lack of enough samples to determine the long-term impact of 3D customized prostheses on the human body, which has hidden risks. Hospitals should record and regularly visit all patients who have been implanted with 3D custom prostheses and should not publicize 3D customization technology.

6. Conclusion

The conclusion of this article is that 3D modeling and printing technology has played a great role in medical treatment, but there are still shortcomings in terms of cost and materials. Due to the limitation of professional knowledge and reading amount, this article still has many inadequacies. In the future, I will continue to pay attention to this topic and collect and read more data.