1. Introduction

1.1. Background of the topic

In the past few decades, robotics has experienced rapid development. Nowadays, different kinds of robots are used in many fields closely related to human life. Among them, the role of robots in hazardous professions is particularly striking. For example, nuclear waste cleaning robots, firefighting robots and mining rescue robots. These robots work well in high-risk environments that are difficult for humans to work in. With the application of these robots, some tasks that were difficult for human beings in the past have become well qualified by robots.

1.2. Literature Review

To date, the number of research and application reports on rescue robots is accelerating. According to research [1], firefighters on duty typically carry 50-60 pounds of equipment. As a result, all actions firefighters make at the disaster scene require a great amount of physical energy. However, firefighters often have to remove large amounts of debris that have accumulated in passageways by hand, thus it is often difficult and lengthy. The use of Thermite Firefighting Robots [1] has greatly improved this situation. The rescue work after the mine accident is a thorny problem. Research [2] shows that the probability of survival of people trapped after a mine accident is negatively correlated with the time spent in search and rescue. Typically, rescuers are on the back foot for 8 to 12 hours after an accident, as mine managers gather information. In opposition to the slow collection of information by humans, mine rescue robots [2] can penetrate into collapsed mines through narrow gaps and provide rescuers with real video information, which results in a fast and intuitive rescue process. This allows rescuers to anticipate difficulties before they enter the mine, and prepare ahead of time. Subsequently, the search and rescue process has been greatly accelerated, and more trapped people would be rescued. Besides, robots are also playing an increasingly important role in handling nuclear accidents. On March 11, 2011, the earthquake and tsunami threw the Fukushima Nuclear Plant into a major crisis. It was impossible to approach the reactor for survey research [3]. In this case, the robot Quince withstood high levels of radioactive contamination, collected information from inside the reactor and returned successfully. Therefore, TEPCO workers are allowed to quickly reboot the spray system later [3].

The main purpose of this paper is to explore the evaluation criteria applicable to rescue robots and evaluate the robots. To this end, the operating principles of robots in hazardous professions will first be introduced, and two evaluation criteria for such robots will then be proposed. Meanwhile, several robots will be evaluated against these two criteria. Some recommendations will be provided at the end.

2. Operating Principles

2.1. General Principles

Rescue robots often face complex and unknown dangerous environments. Accordingly, the latest humanoid robots can recognize obstacles intelligently. Finally, through the internal AI and external manual guidance, the rescue robot can successfully rescue the trapped victims. The rescue robot can be controlled wirelessly or wired, and its movement can be guided by ultrasonic sensors that steer it away from obstacles in its path. At the same time, the purpose of using thermography is to find living bodies and distinguish them from cadavers [4].

2.2. Specific Principles

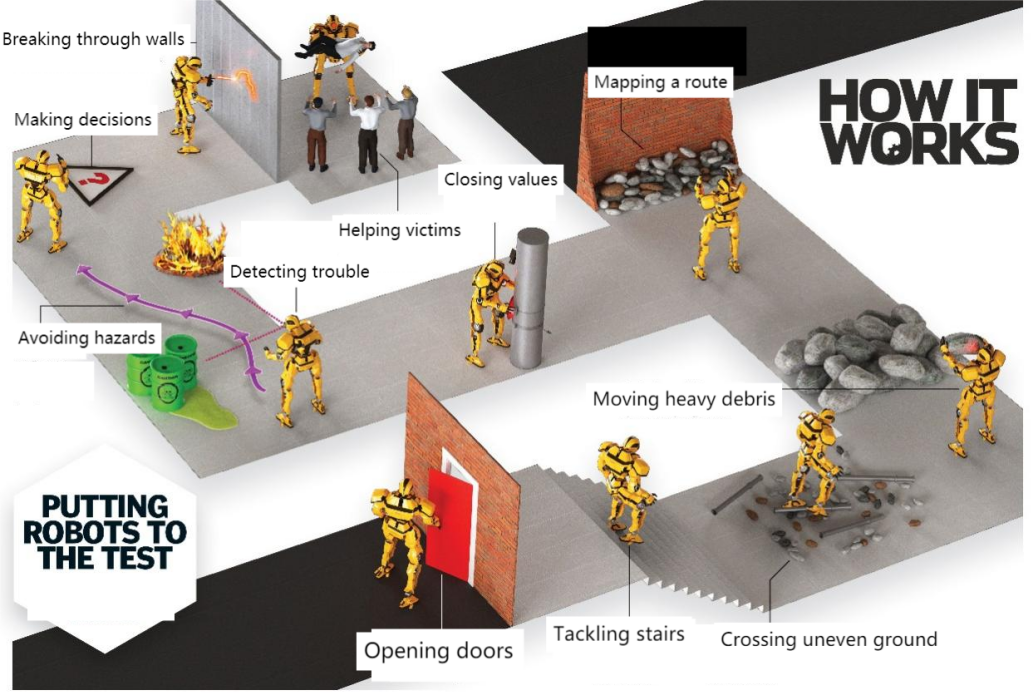

It is clear that there are 10 stages in the rescue process, as shown in Figure 1 [5]. The process begins with access to the scene, and ends with a successful rescue. Before reaching the trapped person, the robot will need to move past the uneven ground and clear obstacles that are unavoidable in its path. At the fifth stage in the process, the robot maps a route, remembers where it has been to help it get out again. Next, in some leaks, the robot has to manually close the valves. Furthermore, as some flammable, explosive or radioactive objects will appear along the path of rescue, the robots will identify and avoid them. Finally, the cutters carried by the robots will cut through the final barrier, allowing the trapped victims to be evacuated.

|

Figure 1. Rescue Robot Rescue Process [5]. |

3. Critical Evaluation

3.1. Evaluation for capability

The term refers to what a robot can achieve in practical use. The goal of robots in hazardous professions is to reduce human casualties in high-risk occupations. For this standard, in fact, robots of this kind are developed to solve a particular problem in a particular situation most of the time. For example, the birth of the Thermite firefighting robot can effectively solve the limitation of rescue channels in the fire scene [1]. Besides that, robot Quency can absorb large doses of radiation while collecting information from around the damaged reactor [3]. In addition, mine rescue robots can effectively and quickly locate survivors from collapsed mines that are inaccessible to humans [2]. However, this design always causes limitations to the practical application of robots. As mentioned above, these robots have highly restricted functions such as firefighting robots opening tunnels [1], mine rescue robots detecting survivors [2], and Quency robots collecting data [3]. As these robots generally only have a few specific functions to perform, this criterion is met.

3.2. Evaluation for practical acceptability

This term refers to the robot's ability to adapt to the complex operating environment. The risk of handling accident is largely due to the complexity and uncertainty at the scene of the accident. Therefore, robots in hazardous professions are required to have strong adaptability to the environment [6]. According to the report, the software and hardware of all three robots are adaptable to certain environments. Nonetheless, the fire-fighting robot mentioned above [1] often fails to play an ideal role in the face of the fire building with a relatively complex corridor structure. Similarly, when the channel at the accident site is too narrow and the water is too deep, the robot Quency cannot pass through smoothly [3]. The report also noted that mine search-and-rescue robots frequently lost contact due to damaged communication cables [2]. At present, robots are not nearly as nimble as humans when it crosses uneven and unpredictable ground [7]. Taken together, these facts suggest that robots perform poorly in consideration of this criterion.

3.3. Other possible problems and solutions

It should be noted that in actual cases, the wireless communication in the disaster area is basically paralyzed, which means that the wireless communication means based on the base station cannot be used normally [8]. At the same time, the existing wireless communication equipment may not be used normally in the disaster area because of various communication interference factors. So, robots should be able to access disaster sites while overcoming these obstacles. We found that in the above rescue robot case, there was less description of the design of data communication between the robot and the operator. One commonly used solution was to use wired communication, but wired communication was limited by the length of the wire and the possibility of the wire being cut. A solution is proposed to solve the communication problem of rescue robots.

Some researchers propose a segmented robot design and a multi - hop communication method that can maintain wireless communication [9]. The communication robot has a modular design, with each module having a wireless router, so when the communication signal weakens, the last module is separated and left in place to be used as a signal repeater, transmitting wireless data from the robot that continues to move forward back to the operator. To complete the wireless signal transmission over a longer distance. If this communication technology is combined with several rescue robots mentioned above, relatively stable data communication between operators and rescue robots can be realized.

3.4. Suggestions

As mentioned above, robots in hazardous professions generally have the problems of single function and poor adaptability to the environment. In regard to the first standard, the requirements that may be involved in the practical application of the robot should be fully considered from the beginning of the design stage, so as to design different functional modules for timely combination and adjustment in actual use [10]. With reference to the second criterion, further actions are needed in two stages: design and use. In the design stage, a complex environment should be considered as far as possible, and corresponding countermeasures should be made. In the use stage, the robot should be avoided in an unsuitable environment.

4. Conclusion

This paper has achieved the aim of evaluating the robots in hazardous professions from capability and practical acceptability. Users and designers of this type of robot can evaluate whether a robot has a high value of use through this standard. In terms of capability, although it is impossible for the three robots mentioned in the paper to complete different kinds of tasks, they manage to complete the basic task objectives in the plan, which meets the standard comprehensively. In terms of practical acceptability, the three kinds of robots mentioned in this paper have examined the running state of robots in different environments in the design stage. However, according to the actual operation cases of robots, these robots perform poorly in relatively complex environments and cannot meet expectations. Therefore, it is assumed that none of the three robots meets this criterion.

There are some limitations of this research. For example, the process of collecting and sorting out literature materials is too hasty, and the scope of browsing related materials is limited. As a result, the establishment of evaluation criteria is not supported by facts, and there are few types of robots in hazardous professions for evaluation, thus the results are not convincing. Overall, the results of this report are helpful for robot designers to identify the shortcomings of existing robots and solve the design defects from the perspectives mentioned in the report.