1. Introduction

The field of intelligent robotics has traditionally been dominated by rigid systems designed for precision and reliability [1]. However, rigid robots face significant limitations in unstructured or dynamic settings, which leads to challenges in adaptability, potential damage to fragile items, and safety concerns in collaborative tasks [2]. These challenges are usually addressed at the cost of higher sensing, modelling and computation.

Soft robotics, a growing field of robotics, has emerged to address some of these limitations. Ang et al. [3] define soft robotics as the study of how soft materials and structures can be utilized to build intelligent robots that interact safely and effectively with their environment. Rus et al. [4] provide a comprehensive overview of the design principles, fabrication techniques, and control strategies for soft robots, highlighting their advantages over traditional rigid robots. Unlike their rigid counterparts, soft robots are constructed from compliant materials, allowing for greater adaptability and safer interactions, greatly simplifying the control system. Their flexibility enables them to handle a wider range of objects, including those with irregular shapes or fragile surfaces, making them ideal for applications in healthcare, food handling, and exploration [5].

Within the domain of intelligent soft robotics, Geometric Bonding Grippers have gained prominence for their simplicity and effectiveness, such as multi-finger grippers [6], clamp grippers [7]. These grippers typically consist of multiple soft fingers that can conform to various object shapes, making them versatile for diverse grasping tasks. The complexity of finger grippers is on sensing and controlling systems. There are a large number of joints to control and stress distribution is very computationally heavy [8]. The other difficulty is to evaluate the minimum and proper contact point at object surface which makes it not perform well when gripping very small or irregularly shaped items [9].

To overcome these challenges, the granular jamming gripper was developed, also known as the universal gripper (see Figure 1 for example). This type of gripper leverages the principle of granular jamming, where a bag filled with granular material transitions between flexible and rigid states through the application of vacuum pressure. By molding itself around an object in its flexible state and solidifying upon vacuum activation, it achieves a secure grasp with enhanced stability, even with irregular or fragile items. Universal grippers can be classified according to suction cup material, type, the technologies used to create the vacuum, and the object materials’ geometry and surface roughness [10]. While universal grippers exhibit promising flexibility and utility, they encounter several performance bottlenecks including limited load capacity, insufficient shape adaptability, and insufficient surface adaptability (see Section 2 for detailed discussion).

Figure 1: Regular granular jamming gripper ([11])

To address the above challenges, this paper presents a novel three-layer granular jamming gripper for intelligent soft robotics, inspired by the idea of inflating air to facilitate more fitted shaping of gripper to the object. It is designed to enhance load capacity and shape adaptability. During the investigation of existing grippers applying air inflation, Ho et al.’s movable jaws gripper [12] came into attention. This gripper utilizes compliant rubber materials with pneumatic inflation and movable jaws to conform to various object shapes. Although both grippers apply inflation as a source of force, they are distinct in theory and design.

To demonstrate the functionality and performance of the tri-layer gripper, physical experiments were conducted. The results show that the novel gripper successfully picks up all objects that the original gripper can handle, with improved grip strength and stability. Moreover, the tri-layer gripper demonstrates its advanced adaptability by successfully handling objects that the original gripper cannot, especially those with complex shapes. The study highlights the significant advancements offered by the tri-layer gripper in addressing the limitations of intelligent soft robotic grippers.

2. Limitations of prior work

2.1. Limited load capacity

The load capacity of traditional granular grippers is constrained by the physical properties of the granular material and the vacuum mechanism [13]. Under high loads, granular particles tend to shift and lose cohesion, resulting in reduced gripping strength.

2.2. Insufficient shape adaptability

Traditional granular grippers struggle to conform to objects with complex geometries, such as flat, thin and small objects, or open objects such as a cup. Contact area measurements indicate that these grippers typically achieve less than 50% surface contact with such objects [14].

2.3. Insufficient surface adaptability

Granular grippers can face challenges when interacting with smooth-surfaced objects. Some studies highlight that while electroadhesion enables the manipulation of flat and fragile objects, the gripper encounters difficulties with varying surface properties, such as oily or smooth surfaces [15].

3. Tri-layer gripper design

3.1. Design overview

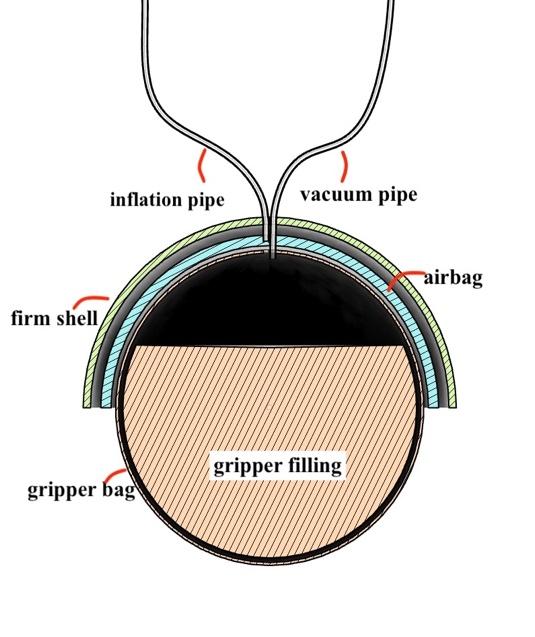

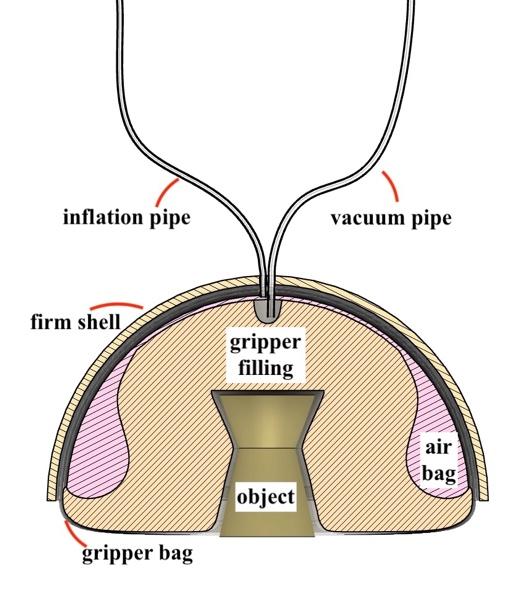

The proposed gripper features a three-layer structure: an outer hard shell to provide structural support and ensures durability under heavy loads (see firm shell in Figure 3 (a)), an inner gripper bag to contain the granular material responsible for gripping objects (see gripper bag in Figure 3 (a)), and an intermediate airbag layer between the hard shell and the gripper bag to exert lateral pressure on the granular material, improving its conformity to objects (see airbag in Figure 3 (a)). The key contribution of the new gripper is the introduction of an airbag that actively presses granular particles against the object’s surface, increasing contact area by adapting to the object’s shape. This not only increases the friction force, but also creates interlocking resistance, altogether increasing the total pulling force, which enables the tri-layer gripper to pick up heavier and irregular shaped objects. To build the final gripper, two air pipes are installed, an inflation pipe is used to pump air into the airbag and a vacuum pipe is used to vacuum the gripper bag (see Figure 3 (e)).

(a) Gripper in relaxed status (b) Gripper in gripping status

Figure 2: Tri-layer granular jamming gripper model

3.2. Building tri-layer gripper

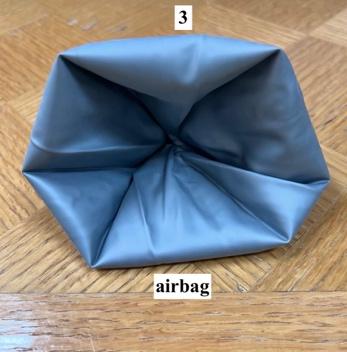

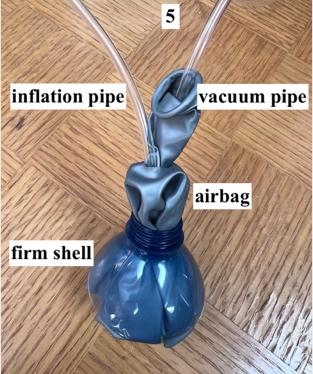

In this subsection, we describe how to build the proposed tri-layer gripper. As demonstrated in Figure 3 (a), materials for building the tri-layer granular jamming gripper include an electrical vacuum (Brekmis [16]), a 500 mL syringe (OLCANA [17]), two plastic tubes, a water bottle cut, a 18 inch latex balloon, a 2.36 inch stress ball, and a bag of millet (approximately 3.5 tbsp used). To build the tri-layer gripper, we first prepare the airbag by cutting a small piece from the bottom of the balloon (see Figure 3 (b)), and then rolling it from bottom to top to form a hollow airbag (see Figure 3 (c)). Next, we assemble the components via attaching one pipe to the airbag and the other one to the gripper bag (see Figure 3 (d)). Last, we pass the pipes and the airbag through the bottleneck and connected the pipes to the vacuum and inflation syringe (see Figure 3 (e)).

(a) Experimental materials (b) Airbag preparation

(c) Finished airbag (d) Assemble components (e) Finished gripper

Figure 3: Steps to make the experimental gripper: a) Prepared materials: a cut bottle top as a firm shell, a hollow airbag made from a latex balloon, and a gripper bag filled with small particles; b) Cut a small piece from the bottom of the balloon; c) Rolled it from bottom to top to form a hollow airbag; d) Assembled the components, attaching one pipe to the airbag and one to the gripper bag; 5) Passed the pipes and the airbag through the bottleneck and connected the pipes to the vacuum and inflation syringe

3.3. Control process for tri-layer gripper

In this subsection, we present the control process for operating the tri-layer gripper. Specifically, the process begins by firmly grasping the rigid outer shell and pressing the gripper against the target object to establish initial contact. Then, the internal airbag gradually inflates, allowing the gripper’s structure to expand and conform precisely to the object’s surface profile and ensuring maximum contact and secure encapsulation. While maintaining inflation, the vacuum mechanism will be activated to extract air from the granular medium, inducing a rigidifying effect that tightly compresses around the object, locking it in place. Once the object is securely grasped, the gripper will be lifted by holding the rigid shell, ensuring a stable and controlled pickup.

4. Experimental setup

To evaluate the performance of the tri-layer granular jamming gripper, we conduct a comparative experiment using two grippers constructed from the same materials. The only difference between them is the presence of an airbag in the tri-layer gripper. The gripper without the airbag functions as a standard granular jamming gripper and serves as the control group.

To ensure a fair comparison, we carefully standardize the experimental conditions. Both grippers are tested under identical environmental settings, with consistent air pressure levels, vacuum strength, and particle type within the gripper bags. Additionally, the same operator performs all tests to minimize variability in handling. To eliminate potential biases, the sequence of object testing is randomized, and each gripper is alternated in testing to prevent any order effects.

The results are then visualized using bar charts, comparing the success rates of both grippers across different object types. These results provide insight into the impact of the airbag on the gripper’s adaptability and gripping strength. Two kinds of experiments are conducted to demonstrate the performance of grippers. One is grasping tests, which show the success rates of grasping various objects of different shapes and sizes. The other is grip force tests, which show the difference in maximum force that are applied to selected objects. The experiments involve picking a set of everyday household objects to assess the effectiveness of each gripper. The selected objects are categorized into two groups: (1) objects that the universal granular jamming gripper could pick up, and (2) objects that the universal gripper struggled to pick up effectively. Each object is subjected to 10 grasping attempts using the same gripping mechanism, ensuring that the force applied, contact angle, and duration of vacuum activation remain consistent. The number of successful picks is recorded for each trial.

5. Experimental results

5.1. Grasping experiments

Following the experimental setup in Section 4, eight objects are selected in the experiment, classified in two categories below (see Figure 4 for images of these objects).

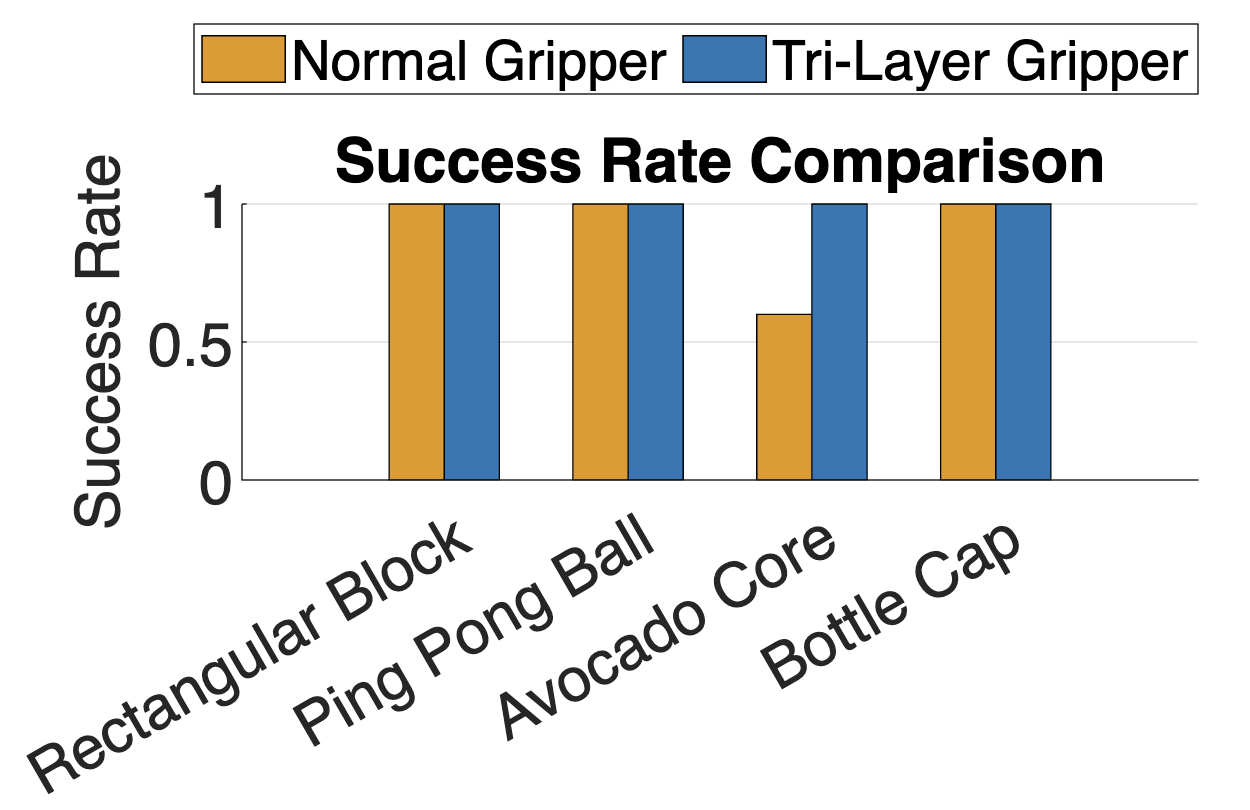

5.1.1. Grasping standard objects

We select the following items as standard objects for comparison (see Figure 4):

• Rectangular Blocks: Due to the rigidity and relatively regular shape of the blocks, the traditional gripper may have trouble with an insufficient contact area or an unstable grip, leading to poor grasping performance.

• Ping Pong Ball: Due to its light weight and spherical shape, the traditional gripper can easily grasp it. However, because the surface of the ping pong ball is smooth, the traditional gripper may slip off or fail to maintain a secure hold.

• Avocado Core: Though the shape of the avocado core is relatively regular, its larger weight makes it difficult for the traditional gripper to maintain a strong grip, causing the item to slip off easily.

• Bottle Cap: The bottle cap is a typical cylindrical item. The traditional gripper can grasp it, but because the height is minor and the surface is smooth, the gripper may slip off or fail to maintain a secure hold.

Figure 4: Experiment objects. First row is composed of standard objects, the second row is composed of complex objects. From left to right, row by row, the objects are: rectangular block, ping pong ball, avocado core, bottle cap, upright cone, inclined GU10 LED bulb, t-shaped hook, and flat piece of block

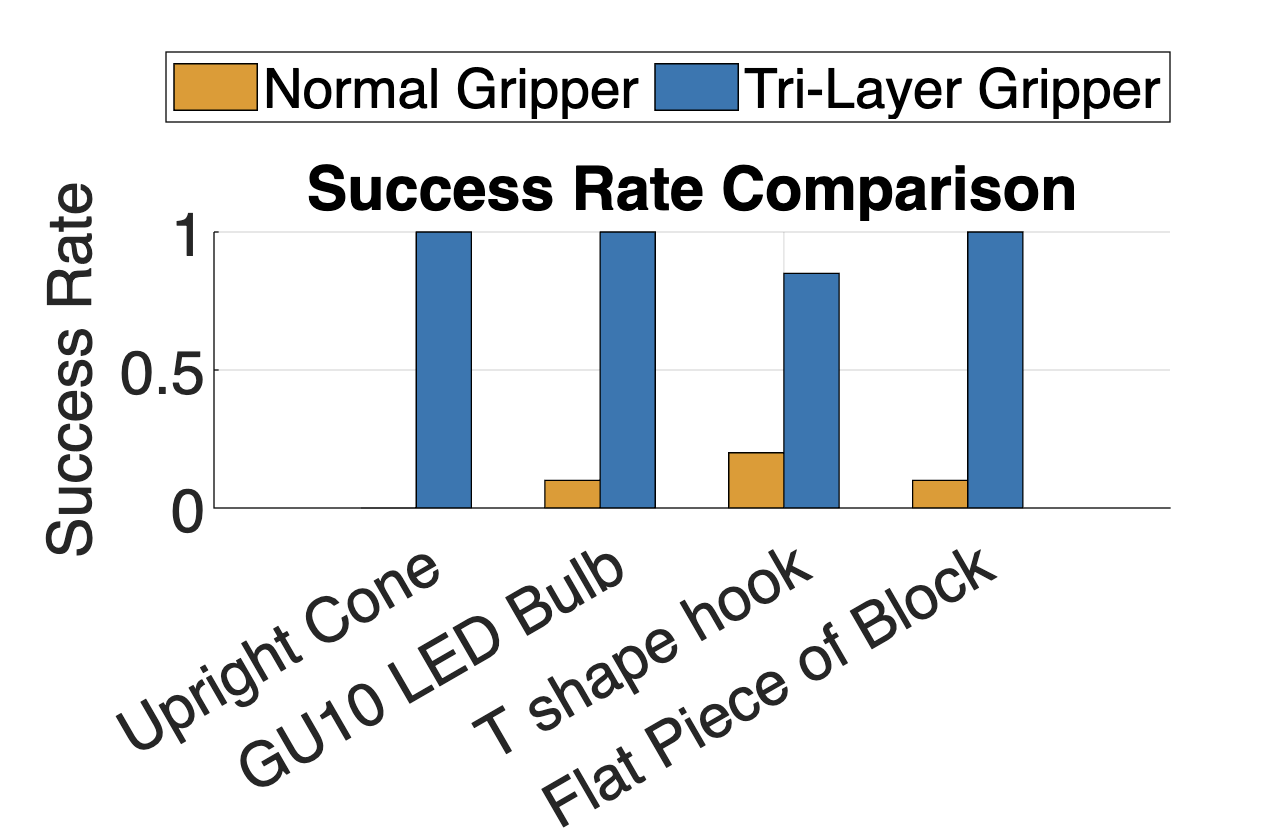

5.1.2. Grasping complex objects

We select the following items as complex objects for comparison:

• Upright Cone: With a narrow top and wide base, as well as a smooth surface, the traditional gripper has difficulty gripping the base, leading to slippage.

• PInclined GU10 LED Bulb: With a smooth surface, a narrow top, and a wide bottom, and due to its heavy weight, the traditional gripper cannot create enough friction to secure the object.

• T shape hook: With a smooth surface and irregular shape, the traditional gripper can only make limited contact, making it difficult to generate enough force.

• Flat Piece of Block: With an irregular surface and thin structure, the traditional gripper cannot create effective contact, leading to minimal gripping force.

5.1.3. Grasping results

The following image shows the gripper in the action of gripping objects.

Figure 5: Tri-layer gripper when gripping

In the standard objects experiment, objects can be gripped by both universal gripper and tri-layer gripper. In the experiment involving complex objects, the tri-layer gripper could grip objects that the universal gripper could not grip or could not consistently grip. The grasping results show that the tri-layer gripper generally performs better than the universal gripper.

(a) Grasping of standard objects (b) Grasping of complex objects

Figure 6: Comparative grasping results for standard and complex objects

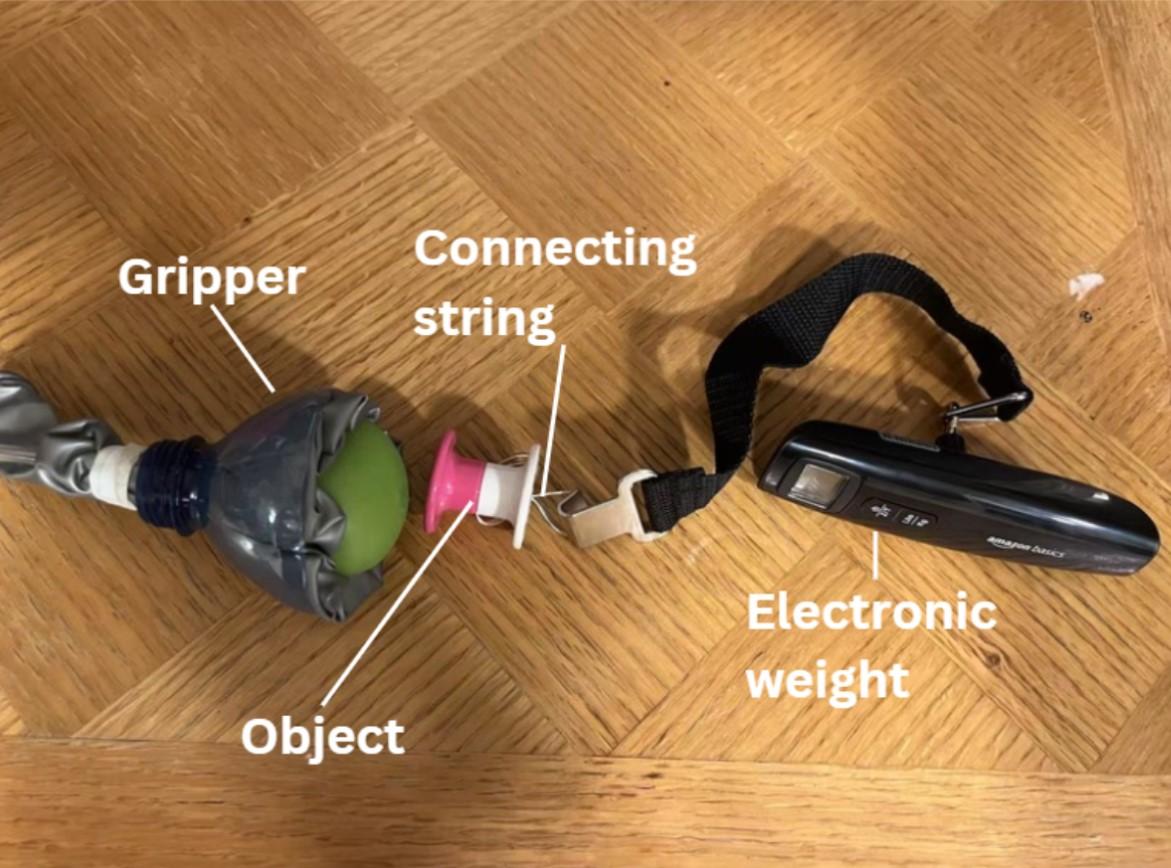

5.2. Grasping force experiments

To measure the gripping force, a portable digital scale is used to test the grip force of universal gripper and tri-layer gripper. Additionally, a string handle is added to each tested object so that the digital scale can attach to the objects.

Figure 7: Gripping force comparison setup

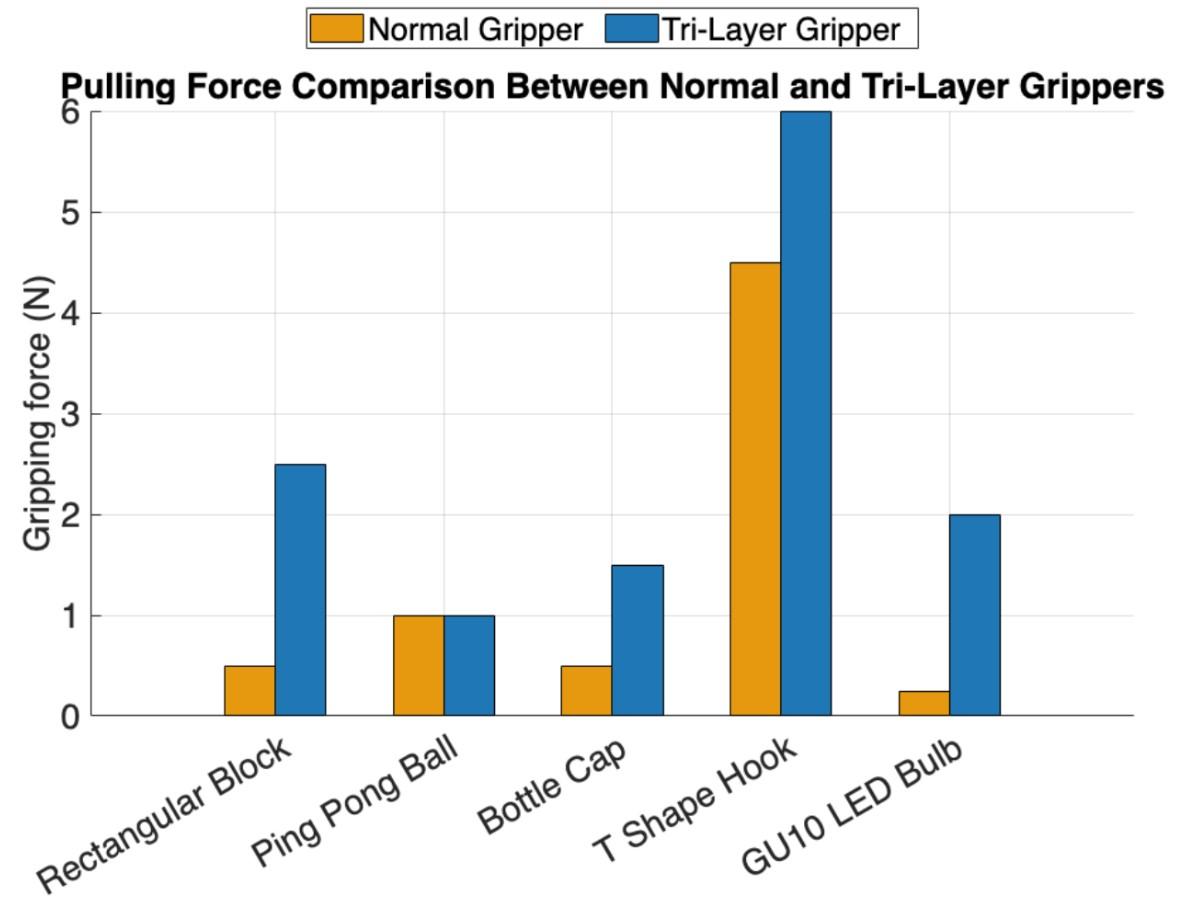

During experiments, five objects are selected to test the gripping force, including a rectangular LEGO block, a ping pong ball, a bottle cap, a T-shaped hook, and a GU10 LED bulb. Gripping force is recorded by reading the digital scale. In total, two tests are made for each object and the mean value of the two records is used to represent gripping force.

Figure 8: Comparative gripping force results for standard and complex objects

As shown in Figure 8, in the case of all the above items, the tri-layer gripper exhibits better performance compared with the normal gripper. Since the novel tri-layer gripper inflates the airbag and applies pressure to the gripper bag, it generates greater friction and conforms more closely to the shape of the object, resulting in a significantly stronger grip. Therefore, the tri-layer gripper demonstrates a better ability to grasp these challenging objects. Furthermore, the tri-layer gripper exhibits superior performance in grasping the tested items with smooth surfaces (e.g. GU10 LED bulb) or greater weight (e.g. rectangular LEGO block). This indicates that the tri-layer gripper can offer a firmer and more stable grip compared to the normal gripper, enhancing overall reliability and control.

6. Discussion

This paper introduces a novel granular jamming gripper with a three-layer structure, developed to address critical performance limitations of traditional grippers in intelligent soft robotics. The gripper incorporates an intermediate airbag between the firm shell and the granular medium, aiming to enhance shape adaptability and grip strength.

The experimental prototype is constructed using toy and household waste materials, leading to several limitations. The oversized airbag does not always fit perfectly within the shell, and the inflation mechanism—a manual syringe—sometimes is inefficient due to minor air leakage. Despite these drawbacks, the tri-layer gripper consistently outperforms the normal gripper without an airbag.

The airbag's ability to expand and apply lateral pressure significantly improved the gripper’s ability to conform to irregular shapes. This enhanced surface contact and better force distribution around the object reduced slippage and increased grip stability. In particular, the tri-layer gripper demonstrates superior performance in grasping smooth or convex objects, a known weakness in traditional granular jamming grippers.

Future improvements to the tri-layer gripper could focus on enhancing material selection and refining the manufacturing process to improve durability, flexibility, and performance. Both the control and experimental designs currently rely on rudimentary materials, limiting efficiency and longevity. Size also remains a constraint, affecting the range of graspable objects. Future iterations might explore miniaturization for delicate applications, or scaling up for heavy-duty use. Additionally, optimizing the airbag and granular medium could yield stronger, more adaptive grips, while integrating more advanced sensors and intelligent control systems would enhance automation and real-time feedback in dynamic environments.

7. Conclusion

The tri-layer granular jamming gripper presents a meaningful advancement over traditional designs, offering improved grip strength, adaptability, and performance in handling smooth or irregularly shaped objects for intelligent soft robotics. The integration of an airbag layer demonstrates clear functional benefits and opens promising directions for future development in intelligent soft robotics.