1. Introduction

In China, gas disasters in mines are extremely severe, and the prevention and control of gas outburst accidents encounter numerous formidable challenges. As the mining depth increases, the geological and engineering conditions become more complex, leading to higher risks of gas disasters and greater difficulties in their prevention and control. Photoacoustic spectroscopy (PAS) technology, characterized by high sensitivity, strong selectivity, and low maintenance costs, shows great potential and broad application prospects in the field of mine gas monitoring. From 2018 to 2022, coal mine accidents presented a "fluctuating asymmetric V-shaped" distribution pattern. The explosive, flammable, asphyxiating, and adsorptive characteristics of mine gas pose significant hazards to human life and safety [1]. The existing methods for mine gas detection methods mainly include: photoacoustic spectroscopy (PAS), non-dispersive infrared spectroscopy (NDIR), differential absorption lidar (DIAL), Fourier-transform infrared spectroscopy (FTIR), and differential optical absorption spectroscopy (DOAS) [2]. When conducting a literature review on research related to multi-component gas monitoring in mine gas, the literature survey method is first employed.A large number of domestic and international literatures on mine safety, gas monitoring, especially those focusing on multi - component gas monitoring in mine gas, are extensively collected and organized. Through systematic analysis of these documents, the current concerning state of mine work safety is clarified, as well as the significant hazards posed by multi-component gases in mine gas, which contain flammable and explosive components, pose to human health are made clear. This highlights the importance of real-time monitoring of multi-component gases in mines. The shortcomings of existing technologies include low sensitivity, poor selectivity, and susceptibility to interference from other gases. The emergence of photoacoustic spectroscopy technology provides a new technical means for real-time monitoring of multi-component gases in mine gas. This study will conduct an in - depth exploration of the feasibility of optimizing photoacoustic spectroscopy technology with the use of high - precision optical components. It aims to offer new ideas and methods for enhancing the performance of photoacoustic spectroscopy and expanding its application scope.

2. Photoacoustic spectroscopy technology

2.1. Principle of photoacoustic spectroscopy technology

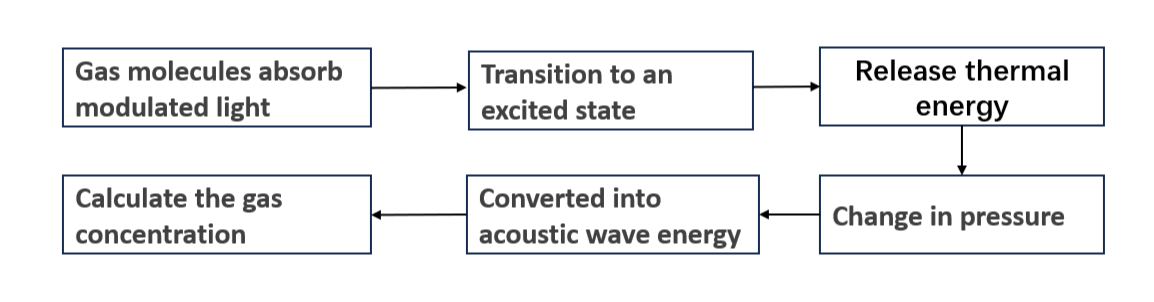

Photoacoustic spectroscopy (PAS) is a technique that measures the sound emitted by gases upon absorbing light energy from a laser. The specific process is illustrated in Figure 1. Gas molecules absorb the modulated light from the laser and transition to an excited state. As excited gas molecules are unstable, they quickly return to a lower energy state. During this transition from the high-energy state to the low-energy state, thermal energy is released. According to the principle of thermal expansion and contraction, the pressure increases, and this pressure change is converted into acoustic wave energy by a transducer. Finally, the gas concentration is calculated indirectly through this sequence of events. Notably, employing high - frequency lasers can optimize this method, significantly enhancing detection sensitivity, as reported in references [3] and [4].\

Figure 1: Schematic diagram of the principle of photoacoustic spectroscopy technology

2.2. Applications of photoacoustic spectroscopy technology

In the photoacoustic cell, gases including carbon monoxide (CO), hydrogen (H₂), and trace moisture (H₂O) are introduced. Owing to the distinct pressure change signals generated after these gases absorb modulated light, their concentrations can be calculated [5]. Photoacoustic spectroscopy (PAS) has demonstrated significant application potential in gas detection due to its advantages of high sensitivity, high selectivity, and non-contact measurement. Particularly in the monitoring of multi-component gases in mine gas, PAS provides new approaches and methods to address the challenges of traditional monitoring technologies. Apart from CO and H₂, PAS is also capable of real - time monitoring of gases such as methane (CH₄), carbon dioxide (CO₂), oxygen (O₂), hydrogen sulfide (H₂S), and trace moisture (H₂O). The underlying monitoring principle lies in the fact that different gas molecules exhibit characteristic absorption of light at specific wavelengths. After absorbing light energy, a thermal effect is generated, causing a local temperature rise and subsequent pressure variations. By detecting the pressure change signals generated by different gases after absorbing light at specific wavelengths, the concentrations of these gases can be calculated.

Photoacoustic spectroscopy technology offers substantial technical advantages:

• High Sensitivity: It can detect gas concentrations at the ppb (parts per billion) or even ppt (parts per trillion) level, meeting the early warning requirements for trace gas leaks in mine gas.

• High Selectivity: By selecting light sources with specific wavelengths, interference from other gases can be effectively avoided, improving monitoring accuracy.

• Real-Time Online Monitoring: It enables real-time online monitoring of mine gas concentrations, providing timely and accurate data support for gas disaster early warning and prevention.

• Non-Contact Measurement: PAS does not require sample pretreatment, avoiding interference with the measured gas, and is suitable for complex and harsh mine environments.

In the domain of mine gas outburst early warning, the application principle of photoacoustic spectroscopy is rooted in the well - known fact that abnormal rises in gas concentration and gas emission typically occur prior to gas outbursts. By using PAS to monitor the trends of gas concentration changes in real time and combining factors such as geological structures and mining activities, a gas outburst early warning model can be established. This enables early warning of gas outburst accidents. The advantages of PAS in this field are significant:

• High Sensitivity: It can detect minute changes in gas concentration, significantly improving the timeliness and accuracy of early warnings.

• Multi-Parameter Monitoring: PAS supports simultaneous monitoring of multiple gas components, providing more comprehensive data for gas outburst early warning.

• 24/7 Continuous Monitoring: It ensures timely detection of abnormal gas conditions, offering strong support for mine safety production.

In summary, photoacoustic spectroscopy technology, with its unique technical advantages and wide range of applications, holds a pivotal position in the monitoring of multi - component gases within mine gas and the early warning of gas outbursts. This technology furnishes robust technical backing for ensuring the safety of mine production.

3. Real-time monitoring of mine gas based on photoacoustic spectroscopy technology

3.1. Characteristics of mine gas

3.1.1. Composition of mine gas

Mine gas mainly pertains to toxic gases in mines. Predominantly composed of methane (CH₄), some cases, it specifically refers to methane alone. Under specific conditions of high temperature and high pressure, coal formation is accompanied by physical and chemical changes, leading to the continuous generation of gas. The main components of mine gas include methane (CH₄), carbon dioxide (CO₂), and nitrogen (N₂), along with trace amounts of carbon monoxide (CO), hydrogen (H₂), hydrogen sulfide (H₂S), and sulfur dioxide (SO₂) [6].

3.1.2. Properties of mine gas

Mine gas displays properties including asphyxiation, combustibility, explosiveness, and adsorption. When the concentration of mine gas in the air significantly exceeds that of oxygen, it can cause symptoms in humans, such as difficulty breathing and dizziness. Owing to the intricate geological conditions of mines and the innate characteristics of gas, mine gas is highly combustible. During mining operations, electrical equipment carried by workers can easily trigger gas explosions. The impure nature of gas itself makes it prone to explosion when exposed to open flames or sparks from electronic devices.

3.2. Classification of real-time multi-component gas monitoring technologies

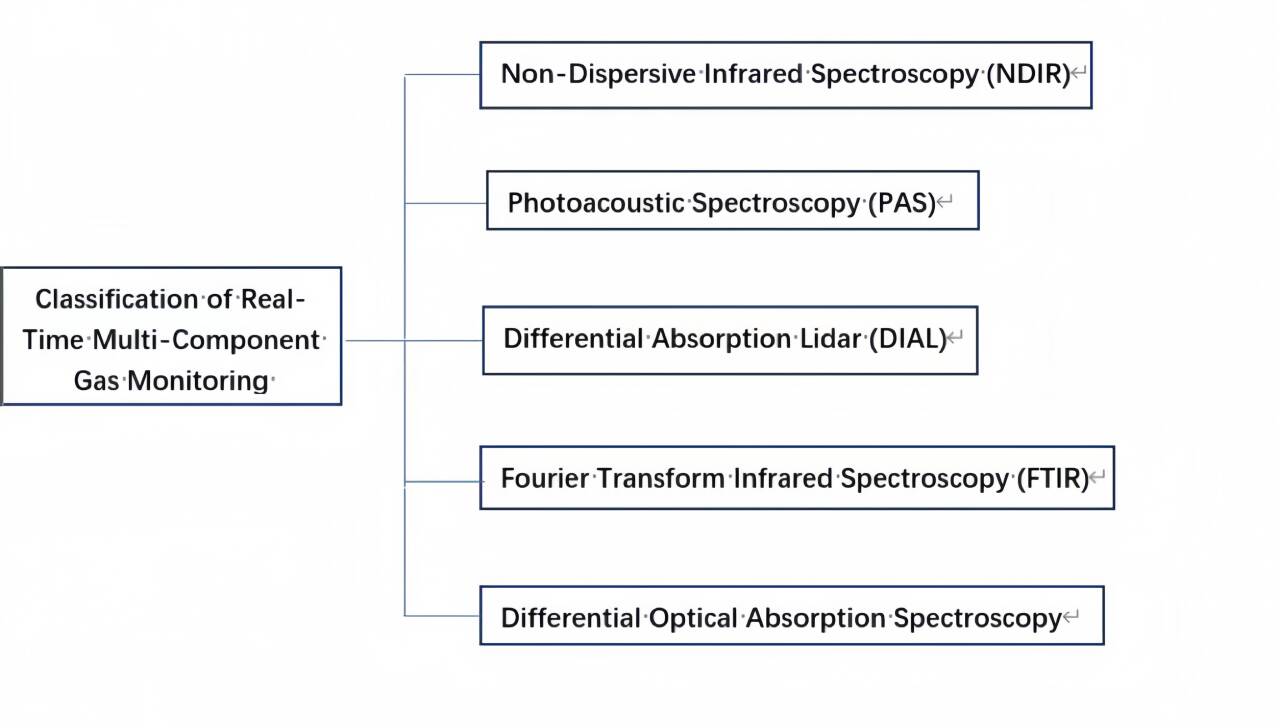

Monitoring methods based on spectroscopy take advantage of the absorption characteristics of gas molecules at specific light wavelengths for detection. These methods are known for their high sensitivity and selectivity and are widely used in real-time multi-component gas monitoring. As depicted in Figure 2, real-time multi-component gas monitoring technologies can be classified into five categories. hotoacoustic Spectroscopy (PAS) is a method used for detecting acoustic signals generated by gas molecules after absorbing light energy. It is suitable for multi-component gas monitoring due to its high sensitivity and non-contact measurement. NDIR, a non-dispersive infrared spectrometer, is used for monitoring gases like methane and carbon dioxide. FTIR, a Fourier transform infrared spectrometer, analyzes gas absorption spectra but is limited by complex equipment and high costs. Differential Absorption Lidar (DIAL) uses lidar to detect gas concentration distributions but is primarily used for atmospheric environment monitoring due to high equipment costs and operational requirements. Differential Optical Absorption Spectroscopy (DOAS) analyzes absorption characteristics of gases in the ultraviolet-visible spectrum but has poor selectivity for complex gas mixtures, limiting its application in multi-component gas monitoring. In summary, spectroscopy-based monitoring methods each have their own advantages and disadvantages. In practical applications, the appropriate technology should be selected based on specific requirements to achieve efficient and accurate gas monitoring goals.

Figure 2: Classification diagram of real-time multi-component gas detection technologies

3.3. Characteristics and classification of photoacoustic spectroscopy technology

3.3.1. Characteristics of photoacoustic spectroscopy technology

Photoacoustic spectroscopy (PAS) demonstrates remarkable high sensitivity, enabling the precise detection of trace amounts of substances. This technology also offers excellent selectivity, allowing for the targeted detection of specific substances while minimizing interference from other factors. Moreover, PAS has the versatility to measure substances in diverse states, such as solids, liquids, and gases. In terms of detector characteristics, PAS does not show wavelength selectivity for to the wavelength of the excitation light. Unlike conventional methods that rely on photodetectors to receive optical signals, PAS utilizes acoustic transducers to capture sound signals. This unique signal reception mode eliminates the need to consider the effects of optical interference during optical path design, which is a critical concern in traditional optical signal reception systems [7].

3.3.2. Classification of photoacoustic spectroscopy technology

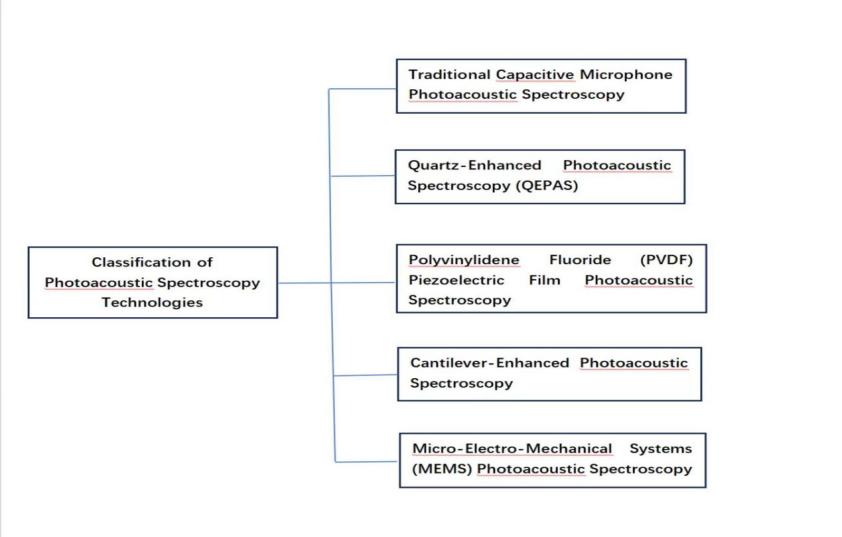

Photoacoustic spectroscopy technology can be classified into five main types in Figure 3:

• Traditional Capacitive Microphone Photoacoustic Spectroscopy: Detects photoacoustic signals through changes in capacitance, suitable for conventional gas analysis.

• Quartz-Enhanced Photoacoustic Spectroscopy (QEPAS): Utilizes the high-quality factor of quartz tuning forks to significantly enhance detection sensitivity, making it ideal for trace gas detection.

• Polyvinylidene Fluoride (PVDF) Piezoelectric Film Photoacoustic Spectroscopy: Employs piezoelectric materials, offering wide-frequency response and rapid response characteristics, suitable for dynamic gas monitoring.

• Cantilever-Enhanced Photoacoustic Spectroscopy: Amplifies photoacoustic signals through the mechanical vibration of cantilevers, suitable for high-precision trace gas analysis.

• Micro-Electro-Mechanical Systems (MEMS) Photoacoustic Spectroscopy: Combines MEMS technology, featuring compact size and low power consumption, making it suitable for portable gas detection devices.

These technologies each have their own advantages and are widely applied in fields such as environmental monitoring, industrial safety, and medical diagnostics.

Figure 3: Classification diagram of photoacoustic spectroscopy detection technologies

3.4. Application of photoacoustic spectroscopy technology in real-time multi-component gas monitoring

3.4.1. Application scenarios

Hu Runze utilized photoacoustic spectroscopy (PAS) technology to detect each gas in a mixed gas sample individually. By identifying optical filters, interference was effectively mitigated. A novel KNN-SVM algorithm was proposed, which combines the advantages of K-Nearest Neighbors (KNN) and Support Vector Machines (SVM) to perform secondary classification on ambiguous data. Experimental findings indicated that, in contrast to the traditional SVM algorithm, the KNN - SVM algorithm showed distinct advantages in gas classification and prediction. It achieved an accuracy rate of 99.167% and an AUC (Area Under Curve) metric of 99.375%. This enables more accurate identification of mixed gas types and concentration inversion. Additionally, considering the impact of temperature on the detection system, the study conducted simulation analysis and practical testing, revealing that temperature variations cause deviations in photoacoustic signal measurements. To tackle this issue, a WOA-BP (Whale Optimization Algorithm-Backpropagation) temperature compensation model was established. Experimental results confirmed that this model performs excellently in terms of prediction fitting and error reduction. These experiments fully demonstrate the feasibility and effectiveness of photoacoustic spectroscopy technology in multi-component gas detection [8].

3.4.2. Technical methods

Zhou Qixuan designed an experiment based on photoacoustic spectroscopy (PAS) technology, which is divided into three main steps [9].

• Design of the Photoacoustic Cell and Optical Path: A non-resonant photoacoustic cell was selected, and its structure was optimized through software simulation. The material and dimensions were determined, and a physical prototype was fabricated. An infrared light source and ellipsoidal reflector were used, and appropriate optical filters were chosen. Considering the interference of water vapor, zinc selenide (ZnSe) was selected as the window material.

• Circuit Design: A preamplifier circuit was designed to preprocess weak signals, and a lock-in amplifier was used to extract useful signals. The circuit was validated through MATLAB simulation. An STM32 development board was programmed to control the relevant components.

• Experimental Validation: Carbon dioxide (CO₂) was used to study influencing factors and determine optimal conditions. Under these conditions, multiple gases were detected, and repeated experiments were conducted to verify stability. The system was also used to monitor gases released by fruits, demonstrating its capability to monitor changes in mixed gas components.

3.4.3. Advantages and disadvantages of photoacoustic spectroscopy

Photoacoustic spectroscopy technology presents substantial advantages in real-time multi-component gas monitoring, prominently featuring “high sensitivity” and “high selectivity” [10]. This technology capitalizes on the photoacoustic effect, where gas molecules absorb light at specific wavelengths, converting light energy into detectable acoustic signals. This mechanism enables precise identification and quantitative analysis of target gases. Given that the generation of photoacoustic signals is directly tied to the light absorption by gases, background interference is negligible, which substantially boosts detection sensitivity. As a result, PAS is especially well - suited for monitoring low - concentration gases. Additionally, the rapid response characteristics of PAS allow for real-time monitoring of multi-component gases within a short time, meeting the demand for fast detection in industrial production and environmental monitoring scenarios. Furthermore, PAS amalgamates the benefits of optical and acoustic detection methods. It showcases excellent resistance to electromagnetic interference and maintains stable performance in complex industrial settings Its simple structure and low cost also make it economically advantageous for large-scale applications. However, photoacoustic spectroscopy technology also has some limitations in practical applications. Firstly, its detection range is constrained by the wavelength of the light source and the absorption characteristics of the gas. For gases with less distinct absorption features, detection sensitivity may significantly decrease, affecting the overall performance. Secondly, the strength and stability of photoacoustic signals are susceptible to environmental temperature and pressure changes. Acoustic sensors are sensitive to these factors, which may lead to reduced detection accuracy. Finally, acoustic signal loss can also impact the final results. This loss occurs on the inner wall surfaces of the instrument cavity and is associated with the type of gas being measured and the material of the photoacoustic cell.However, using photoacoustic cell materials with higher hardness can significantly reduce this loss [11].

4. Conclusion

Photoacoustic spectroscopy (PAS) technology is renowned for its outstanding selectivity, high sensitivity, and low maintenance costs. Mine gas, as a complex multi-component gas system, necessitates real-time monitoring of its components to safeguard mine safety. The application prospects of PAS technology in real-time mine gas monitoring lie in its ability to provide continuous, online, and real-time monitoring, accurately identifying target gases within a mixture of multiple gases. In the future, the challenges for PAS technology include improving its stability and optimizing the detection of gases with less distinct absorption features.