1. Introduction

With the rapid development of the national economy, the role of cars in people's lives has become increasingly prominent. According to statistics, by 2023, China's automobile production and sales have exceeded 30 million, ranking first in the world for 15 consecutive years [1]. Automobile technology is also developing rapidly in the direction of security, intelligence and networking. As an important part of the body control system, auto window control plays a pivotal role in improving vehicle safety [2].

At present, the main hardware used in the research of window control system at home and abroad is MCU system, and the research content mainly focuses on the circuit and algorithm design of anti-pinch threshold points. For example, the current ripple signal FFT processing method is used to obtain the adaptive anti-pinch control of the window position [3], and the circuit diagram is used to diagnose and analyze the single switch control fault and multiple switch control fault of Jetta automobile [4], and the automatic threshold of the electric window current anti-pinch mechanism is studied [5].In this design, Siemens S7-200 Smart PLC is used as the control core to build Mazda right front window lifting control simulation system. Through STEP7 and King view software, the control program and man-machine interface development are realized, and the window lifting and anti-clamp interlock control functions are finally realized. Compared with the traditional single-chip microcomputer control, PLC has powerful control functions and good compatibility, which can better meet the development needs of vehicle intelligence, networking and safety.

2. Automobile electric window control technology

Automobile electric Windows are mainly composed of window glass, window glass lifter, motor, door control unit and control switch. Among them, the car window motor is a 12VDC powered DC motor provided by the car battery. When the motor turns positive and negative, the window lifter is driven to move, and then the car window glass moves up and down. At the same time, due to the huge lifting force of the window in the process of closing, it is easy to have a nip accident when the passengers do not pay attention, which brings safety risks to the passengers. Therefore, the current automatic control of the window, are equipped with the window anti-pinch technology, when the window in the automatic rise of the process of clamping, need to reverse protection, to avoid accidents. Usually the Windows with automatic rise are equipped with anti-clip function.

3. Design requirement

The purpose of this design is to use S7-200 Smart PLC as the control core to develop a Mazda right front window lift control simulation system integrating key and anti-clip control functions to achieve the following functions.

• Press the window button to raise the window. If no foreign body signal is detected during the rising process, the window motor will run normally. When the window opening limit is reached, the motor will stop. In this process, if someone or something enters the detection area, the window motor runs in reverse, and the window drops until it reaches the limit or the obstacle disappears, so as to achieve the anti-pinch function.

• When the window switch is pressed, the window drops, the window motor runs in reverse, and the motor stops when the window limit is reached.

• Provide control program development port and HMI monitoring software, real-time observation of window lifting and foreign bodies into the state.

4. Hardware design

The hardware part uses Siemens S7-200 Smart SR20 CPU, Mazda right front window lifter, photoelectric obstacle detector, window lifter switch for controller, executive equipment, sensor and control equipment. At the same time, UTP1305S DC regulated power supply, RXM2AB2JD intermediate relay and other devices are used to realize equipment power supply and positive and negative rotation control of window motor.

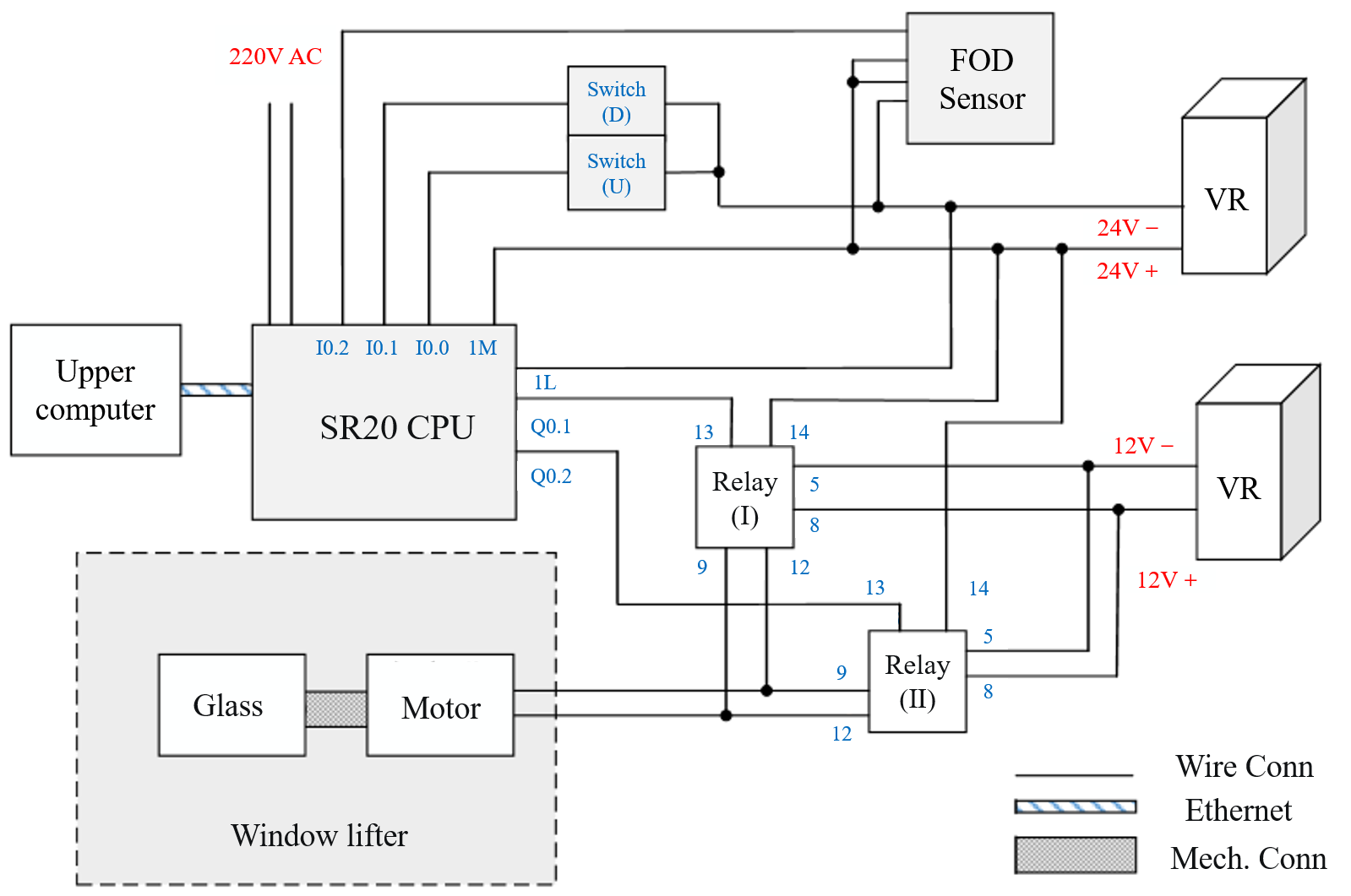

Figure 1. Schematic diagram of hardware wiring

Among them, the Mazda right front window lifter is driven by an electric motor, which moves the window glass up and down. The motor uses a DC motor powered by 12VDC. It drives the window lifter to rise and fall when it moves forward and backward. The photoelectric sensor can detect foreign matter, and can be triggered normally open or normally closed. When an object enters the detection area, its contact will act and send the signal to the controller. The S7-200 Smart SR20 uses 220VAC power supply, relay output, comes with 12 DI and 8 DO channels, and can realize Ethernet communication with the programming host through network cables. The selection of the CPU can meet all the needs of obstacle detection, signal input of lifting control switch and output of positive and negative motor control signal. At the same time, the upper computer can realize programming, download, operation control and real-time monitoring through the STEP7 Micro WIN SMART program. The UTP1305S has two DC regulated power supplies, one for the 2-way relay, sensor and DI input circuit, and one for the window lift motor. According to the design requirements, the design schematic diagram is shown in Figure 1.

Figure 2. Main hardware products and wiring

Figure 2 (a) shows the main hardware products. Among them, the photoelectric obstacle detector uses 24VDC power supply, 24V+ input to the brown line, 24V- input to the black line. The blue and white wires of the photoelectric switch loop with 24V and connect to the I0.2 terminal of the SR20 CPU device. The SR20 CPU uses 220V AC power supply, I0.0 access the ascending window signal, I0.1 access the descending window signal, and input I0.2 access the sensor signal. Q0.0 and Q0.2 are respectively connected to two relays for the window motor lift control. RelayⅠand relayⅡare connected to the actuator loop to control the positive and negative rotation of the window lift motor. They are powered by a 12V voltage regulator, and their coils control their power status through Q0.0 and Q0.2 of the SR20 CPU, respectively, and output to the window lift motor. The connection diagram is shown in Figure 2 (b).

5. Software design

The purpose of the software design is to use STEP7-MicroWin Smart and King view software to develop together to achieve the effect of controlling the window lifting and anti-clip function and human-computer interactive display.

Among them, STEP7-MicroWin Smart is the S7-200 Smart PLC device control software dedicated by Siemens. In this software, it can easily realize the control algorithm writing, compiling, downloading, PLC online monitoring, start, stop control and other functions.

King view is a special interface development software developed by Asia Control Technology Company. The software can realize data communication with S7-200 Smart PLC and visually display information such as foreign object detection and window status to realize man-machine interaction.

5.1. STEP7-MicroWin smart design

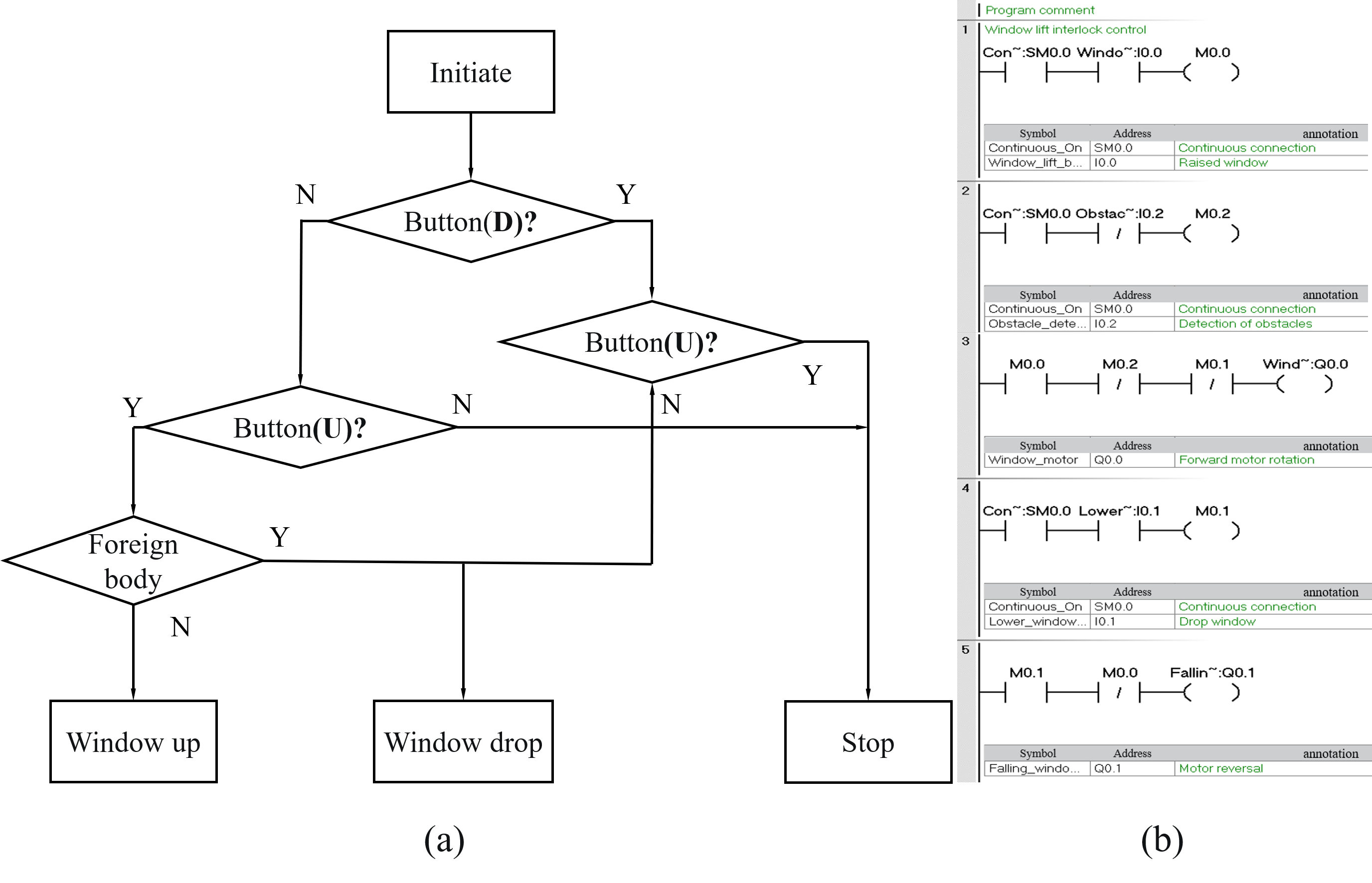

In order to realize the design function, the setting control flow chart is shown in Figure 3 (a). The control program is designed according to the following steps:

(1) Hardware configuration.

(2) Communication connection (in this design, the IP address is set to 192.168.2.1).

(3) Symbol table design. In order to increase the readability and portability of the program, I/O symbols are defined: I0.0 (rising window switch), I0.1 (falling window switch), I0.2 (foreign object detection), Q0.0 (rising window motor), Q0.1 (falling window motor).

(4) Program writing. The main program is written with T-diagram, and the program is divided into different sub-blocks, part of the main program is shown in Figure 3 (b).

(5) program compilation and download. Compile the program after writing, click the "download" icon after success, download it to the PLC and run it.

Figure 3. Control flow chart and screenshot of main program

5.2. King view design

On the HMI, it is necessary to communicate with the SR20 CPU device in real time through STEP7-MicroWin Smart to collect and display the current lifting status of the window, foreign body detection, foreign body detection alarm reminder, and window lifting control buttons. Follow the following steps to develop King view:

(1) Add the driver device.

(2) Add the device. In order to realize the linkage with the PLC device, the communication address of the device is (190.168.2.1:0).

(3) Data dictionary configuration, add data to the data dictionary, and set the data address.

(4) Human-machine interface production, set links.

6. System operation

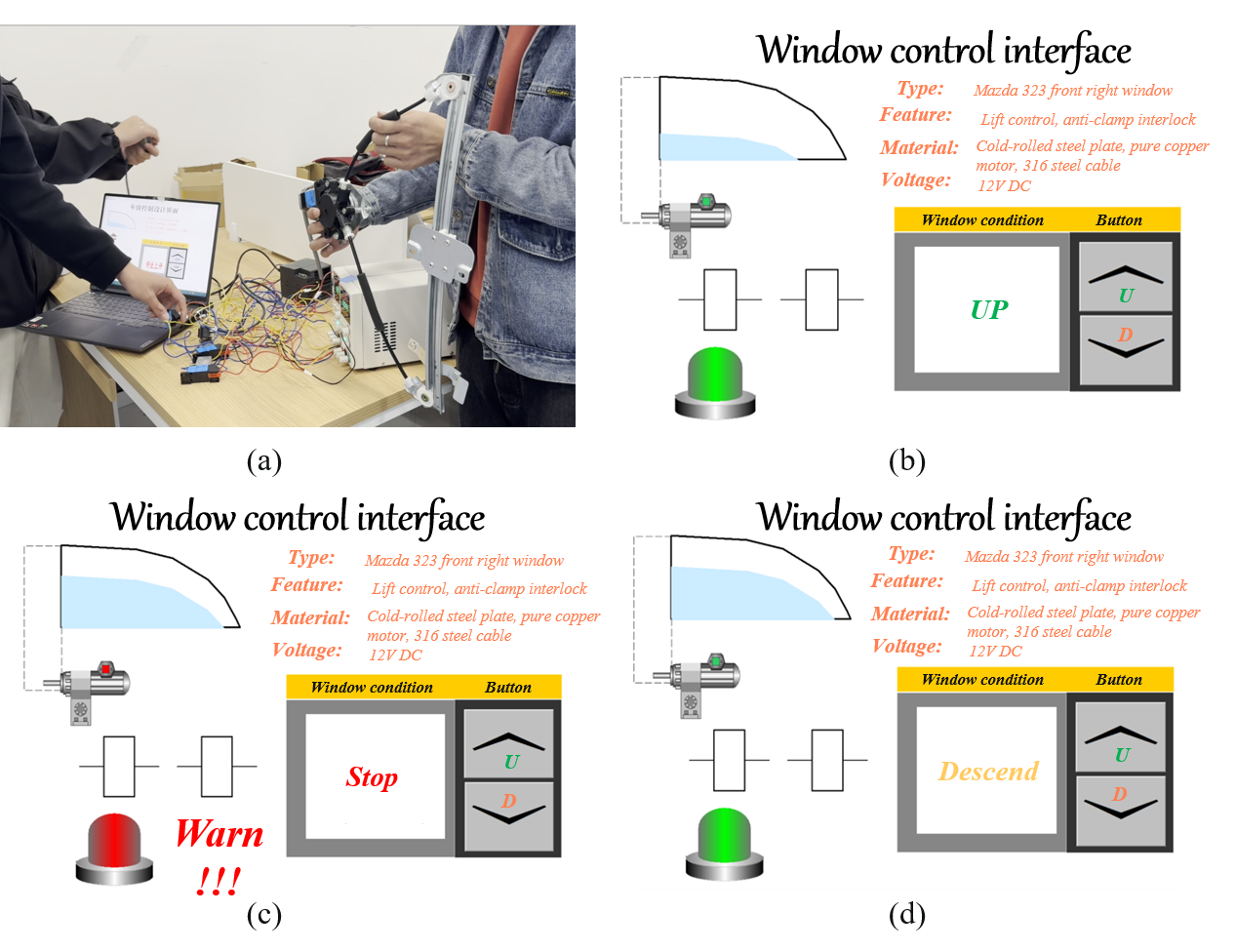

Wiring the hardware equipment according to the schematic diagram, connecting the programming computer with SR20 CPU with network cable, modulating the power supply regulator input of the lifting window switch, sensor and relay 24VDC, adjusting the output parameter of the window motor voltage regulator source to 12VDC, and connecting the SR20 CPU to 220VAC for power supply operation of the equipment. As shown in Figure 4 (a). In the human-machine interface of King view, click "Switch to VIEW" to run the program. Press the window lifter switch, and no input is received for foreign body detection. At this time, the King view interface displays the rising action, as shown in Figure 4 (b), and the window lifter rises. Press the window lift switch and the window rises. At this time, put your hand within the detection range of the sensor. The display of the King view interface is shown in Figure 4 (c). The window lifter stops rising and gives an alarm. Press the drop window switch, the display of King view interface is shown in Figure 4 (d), and the window lifter is lowered. Because there is a logical interlock, the window lift switch is pressed at the same time, and the window does not move. Through actual operation, the device can realize the control of window lifting under normal conditions, and trigger the anti-clip control when foreign objects are detected, and the performance is stable and the response is sensitive, and the operation of the device can be observed at any time through the man-machine interface to meet the design requirements.

Figure 4. System operation

7. Conclusions

The device uses S7-200 Smart SR20 CPU as the control core, and adopts the way of software and hardware co-development to realize the automatic lifting and anti-clip control of car Windows. Through the hardware physical verification, the whole function of the system is complete, the operation result is good, and the expected design goal is reached.

At present, auto window automatic control is mainly realized based on single chip microcomputer or embedded system. In this study, the PLC system with powerful function and strong compatibility in rail vehicle and industrial control is used to realize window control, which provides a new research direction and ideas for window control system research and vehicle intelligent and networked control. At the same time, the construction of the software and hardware platform can also be used as the practical teaching of PLC system and automobile control system in colleges and universities, which has high research and application value.